Model 4P14 Flat Deck, Closed Front

Installation, Operation and Maintenance

4 Rev 08/11/17

4P14-X-IOM-A.doc

Receiving

The shipment should be thoroughly inspected as

soon as it is received. The signed bill of lading is

acknowledgement by the carrier of receipt in good

condition of shipment covered by our invoice.

If any of the goods called for on this bill of lading are

shorted or damaged, do not accept them until the

carrier makes a notation on the freight bill of the

shorted or damaged goods. Do this for your own

protection.

NOTIFY Challenger Lifts AT ONCE if any hidden

loss or damage is discovered after receipt.

IT IS DIFFICULT TO COLLECT FOR LOSS OR

DAMAGE AFTER YOU HAVE GIVEN THE

CARRIER A CLEAR RECEIPT.

File your claim with Challenger Lifts promptly.

Support your claim with copies of the bill of lading,

freight bill, and photographs, if available.

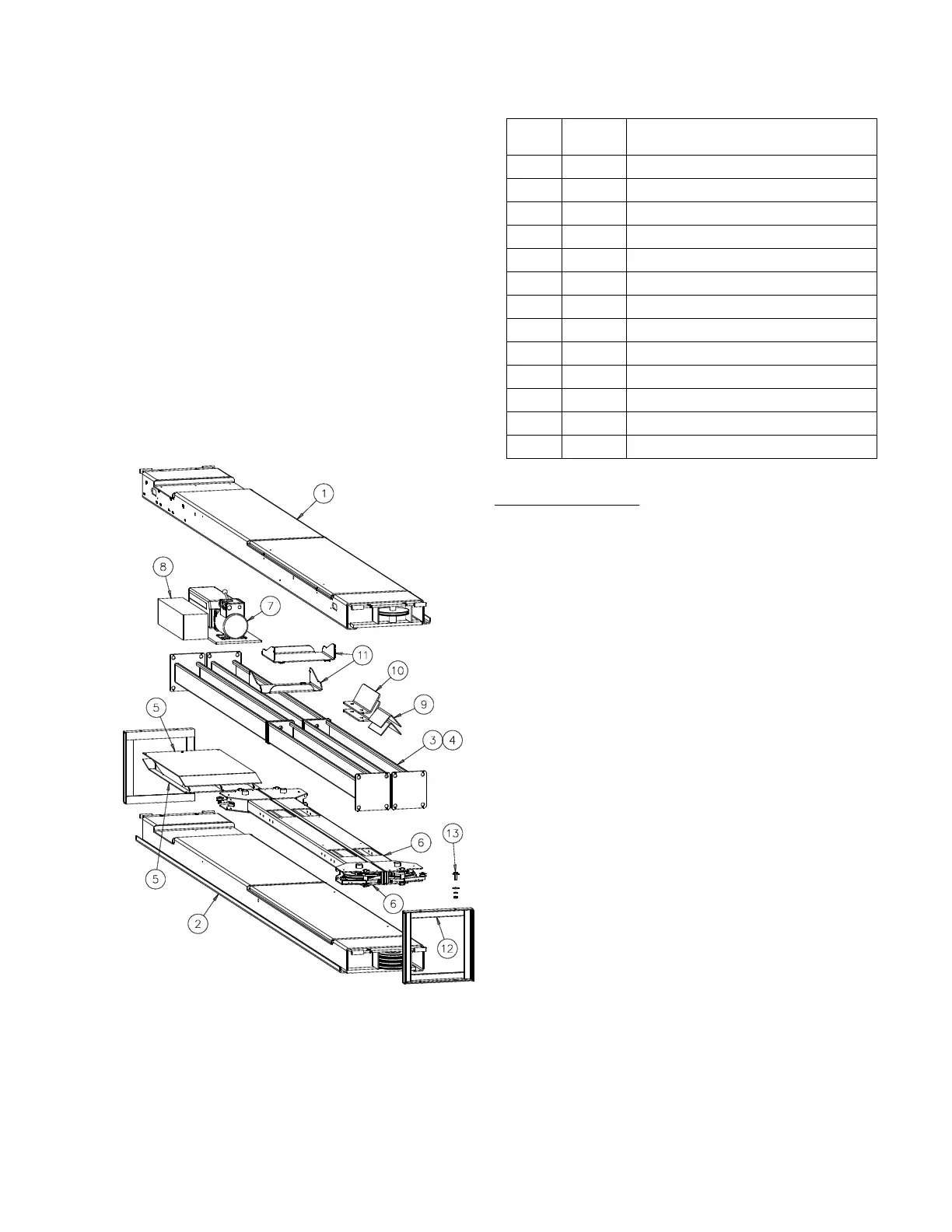

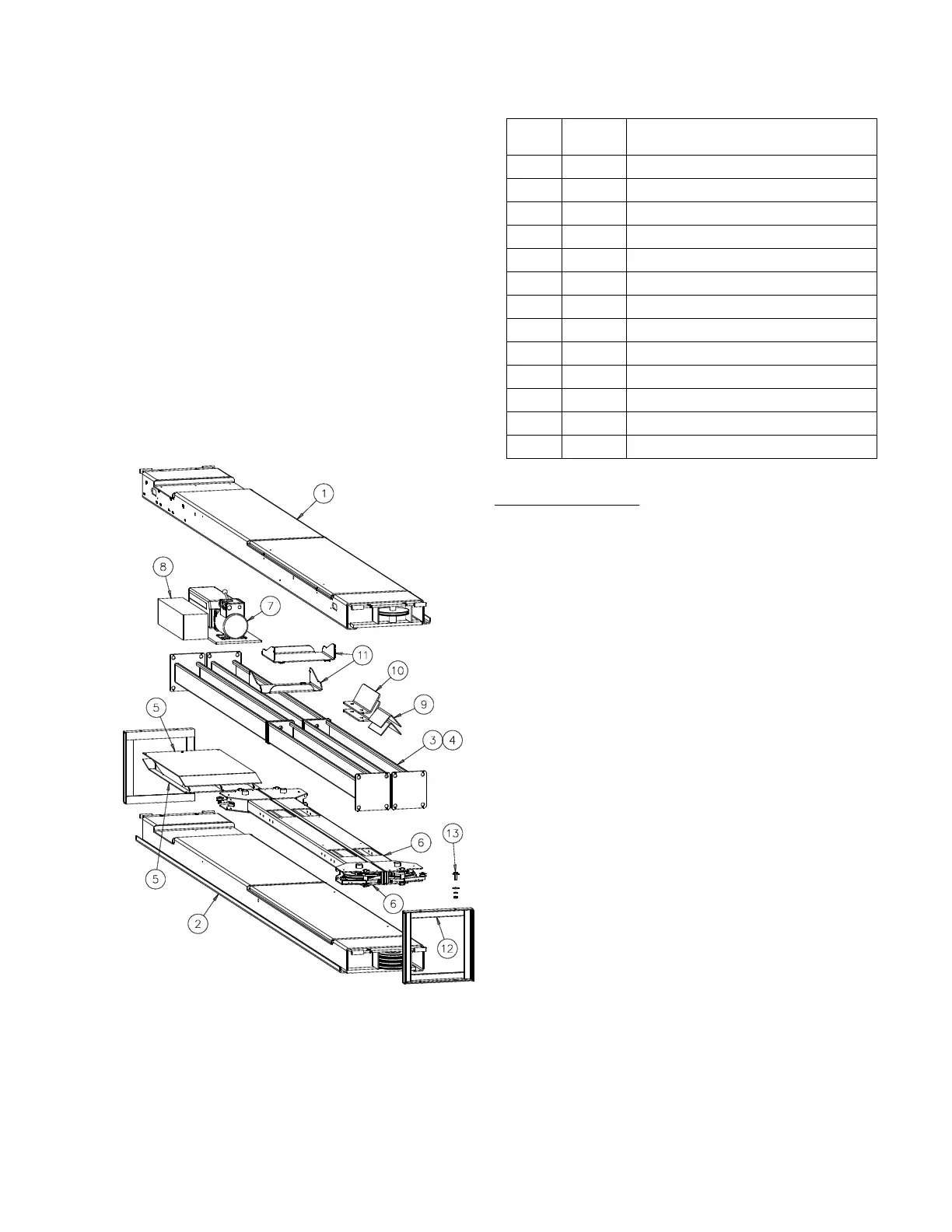

Fig 2 – Package Components

Component Packing List

ITEM

#

QTY/

LIFT

DESCRIPTION

1 1 IDLER RUNWAY ASS’Y.

2 1 POWER RUNWAY ASS’Y

3 1 POWER COLUMN ASS’Y

4 3 IDLER COLUMN ASS’Y

5 2 ENTRANCE RAMP WELD

6 2 CROSS BEAM ASS’Y

7 1 POWER UNIT

8 1 HARDWARE BOX

9 2 MOVABLE WHEEL CHOCK

10 2 FRONT WHEEL STOP

11 2 WORK STEP (alignment lifts only)

12 2 SHIPPING BRACKET WELD

13 8 ½” SHIPPING HARDWARE

INSTALLATION

IMPORTANT: Always wear safety glasses while installing lift.

TOOLS (MINIMUM REQUIRED)

a. Tape measure, 25ft

b. Chalk line

c. 4ft level

d. 10” & 12” adjustable wrench

e. Standard open end wrenches 3/8”, 7/16”, 1/2",

9/16”, 5/8”, (2) 11/16”, 3/4", 15/16”, 17mm

f. 6mm allen wrench

g. Box knife

h. Thread locking compound

i. Thread tape sealant (for air line)

j. Needle nose pliers

k. Hammer drill with 3/4” diameter carbide tipped

bits

l. 2lb hammer

m. Torque wrench: 150 foot pounds minimum with

1 1/8” socket

n. 8 ft. Step ladder

o. Blocking – (4) 4x4x30”, (4) 1x4x12”

p. Transit for leveling alignment lift

L

AYOUT

1) Lay out the service bay according to the

architect’s plans or owners instructions, Fig 1.

Be certain that the proper conditions exist, see

page 3.

2) Unpack lift. Remove all packaging from Power

Runway (power runway has four cable sheaves

at rear end) and pull threaded cable ends out.

Make sure the cables are in the proper sheaves

at the 4-stack, Fig 3.

Loading...

Loading...