Model 4P14 Flat Deck, Closed Front

Installation, Operation and Maintenance

8 Rev 08/11/17

4P14-X-IOM-A.doc

31) BE CERTAIN ALL FITTINGS AND CONNECTIONS

ARE

TIGHT. IT IS THE INSTALLERS

RESPONSIBILITY TO INSURE SYSTEM IS LEAK

-

FREE. Fill the Power Unit with three gallons of

clean 10wt anti-foam anti-rust hydraulic oil or

Dexron III ATF. D

O NOT USE OILS WITH

DETERGENTS.

32) Energize the power unit and raise the lift

approximately 1 ft off the ground and look

underneath the power runway to verify that

the cable lugs are resting firmly against the

cylinder pull bar.

33) Level the runways and crossbeams using a 4

ft. level. With the lift resting in its locks, find

the highest corner and adjust the other three

column ladder bars until the runways are

level front-to-rear and side-to-side. Tighten

jam nut against bottom side of each column

top plate.

34) Adjust cables until all four locks are

synchronized when lift is raised. Tighten

cable jam nuts against adjustment nuts.

35) Install 4mm air line from air valve assembly

thru opening in runway to Tee fitting. Fig 12.

FRONT

4mm AIR LINE

4mm TEE

POWER UNIT

w/ AIR VALVE

ASS'Y

REAR

4mm TEE FACTORY

INSTALLED AT EACH

CROSS BEAM END

4mm SPLICE

4mm TEE FACTORY

INSTALLED AT EACH

CROSS BEAM END

FRONT

4mm TEE

4mm SPLICE

POWER UNIT

w/ AIR VALVE

ASS'Y

4mm AIR LINE

REAR

4mm TEE FACTORY

INSTALLED AT EACH

CROSS BEAM END

FRONT

4mm TEE

4mm SPLICE

POWER UNIT

w/ AIR VALVE

ASS'Y

4mm AIR LINE

REAR

4mm TEE FACTORY

INSTALLED AT EACH

CROSS BEAM END

FRONT

4mm TEE

4mm SPLICE

POWER UNIT

w/ AIR VALVE

ASS'Y

4mm AIR LINE

REAR

Fig 12 – Lock Release Air Line Routing

36) Route power side front and rear cross beam

air lines through power runway to Tee fitting.

Route idler side front and rear cross beam air

lines through idler runway and connect

together with 4mm air line splice provided.

Route airline through welded rings on the

outside internal edge of runways.

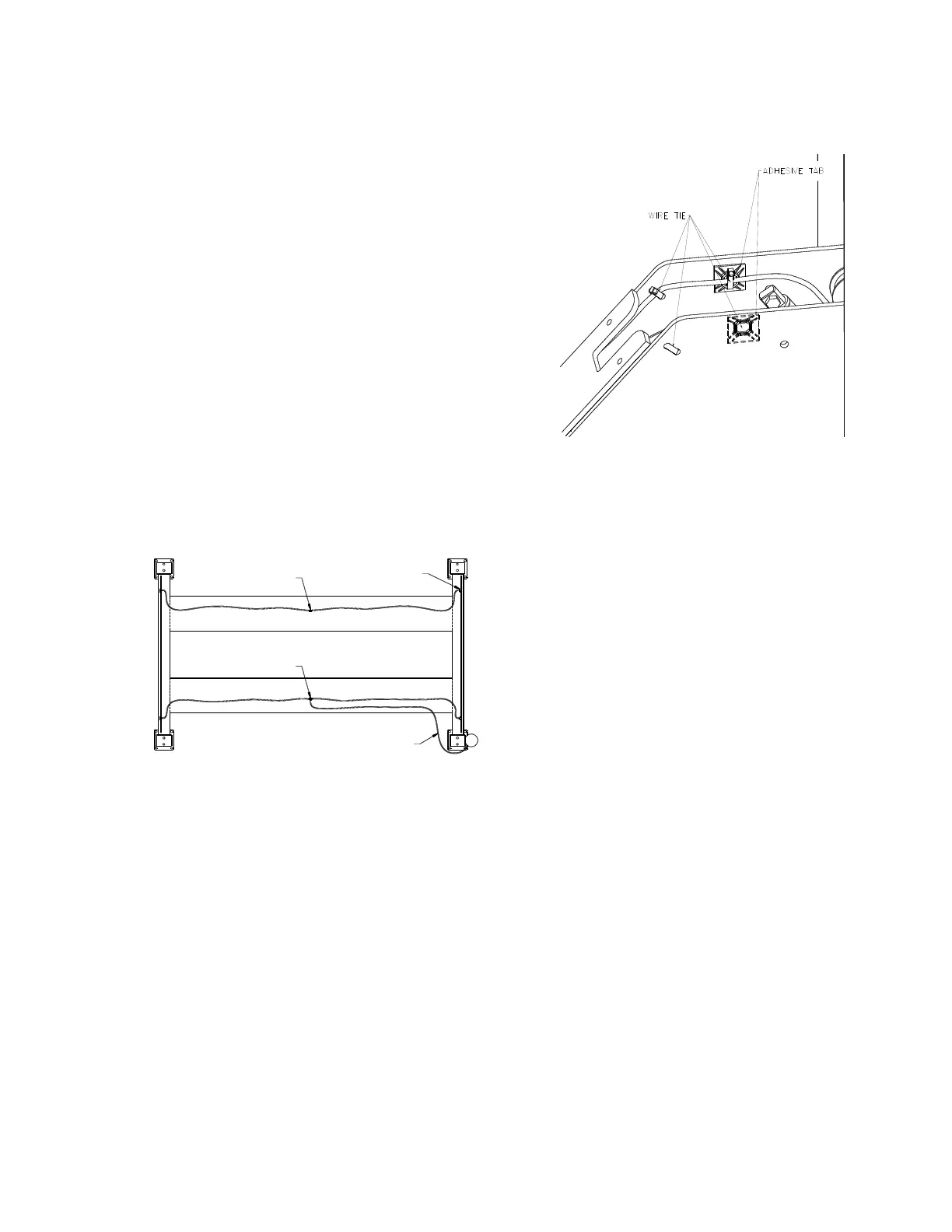

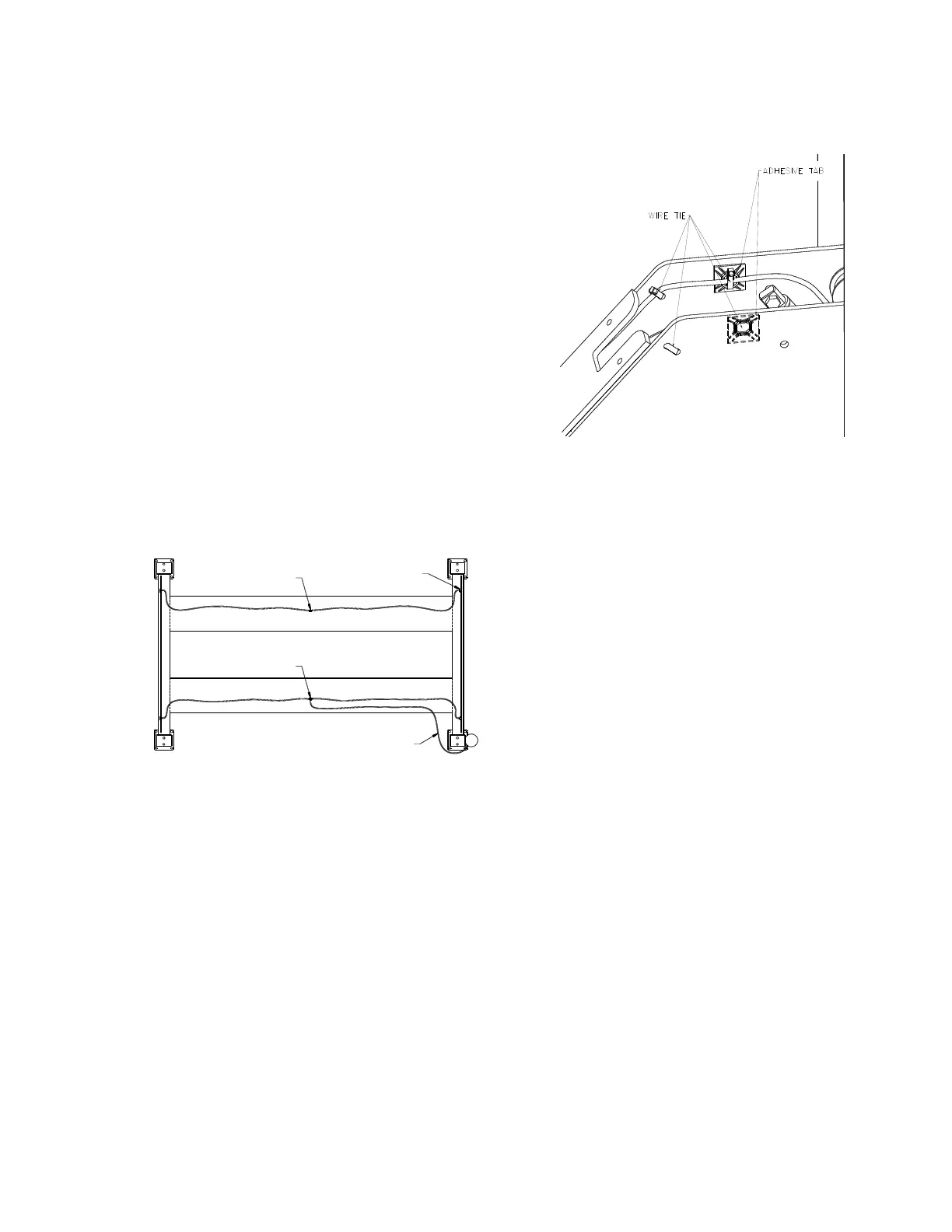

37) Use the provided wire ties and adhesive tabs

to connect the 4mm air line inside the ends of

the front and rear cross beam to the side

plate welds as shown in Fig 13.

Fig 13 – 4mm Air Line Connection

38) Use the hose barb and clamp provided to

connect the button valve to a suitable air

source. Air supply must be clean, dry,

lubricated, and regulated to 90-120 psi.

The FRL, must be within 30 feet of valve.

Failure to provide clean, dry, lubricated,

and pressure regulated air will void

warranty on pneumatic components.

39) Energize air valve assembly and insure that

all air cylinders are working properly.

40) Raise and lower lift several times to bleed

hydraulic cylinder. Hydraulic cylinder is self-

bleeding. Lower lift and check fluid level in

reservoir. Add fluid as needed.

41) Run lift to full rise and continue running motor

approximately 5 more seconds. Check

hydraulic hose and connections for leaks.

Re-tighten fitting if leaking.

42) Raise lift approximately half way. Slowly jog

power unit until you hear one of the locks

engage. Adjust locking ladder until it just

barely raises the crossbeam end. Back off

1/2 turn. Repeat for each column.

Loading...

Loading...