Model 4P14 Flat Deck, Closed Front

Installation, Operation and Maintenance

5 Rev 08/11/17

4P14-X-IOM-A.doc

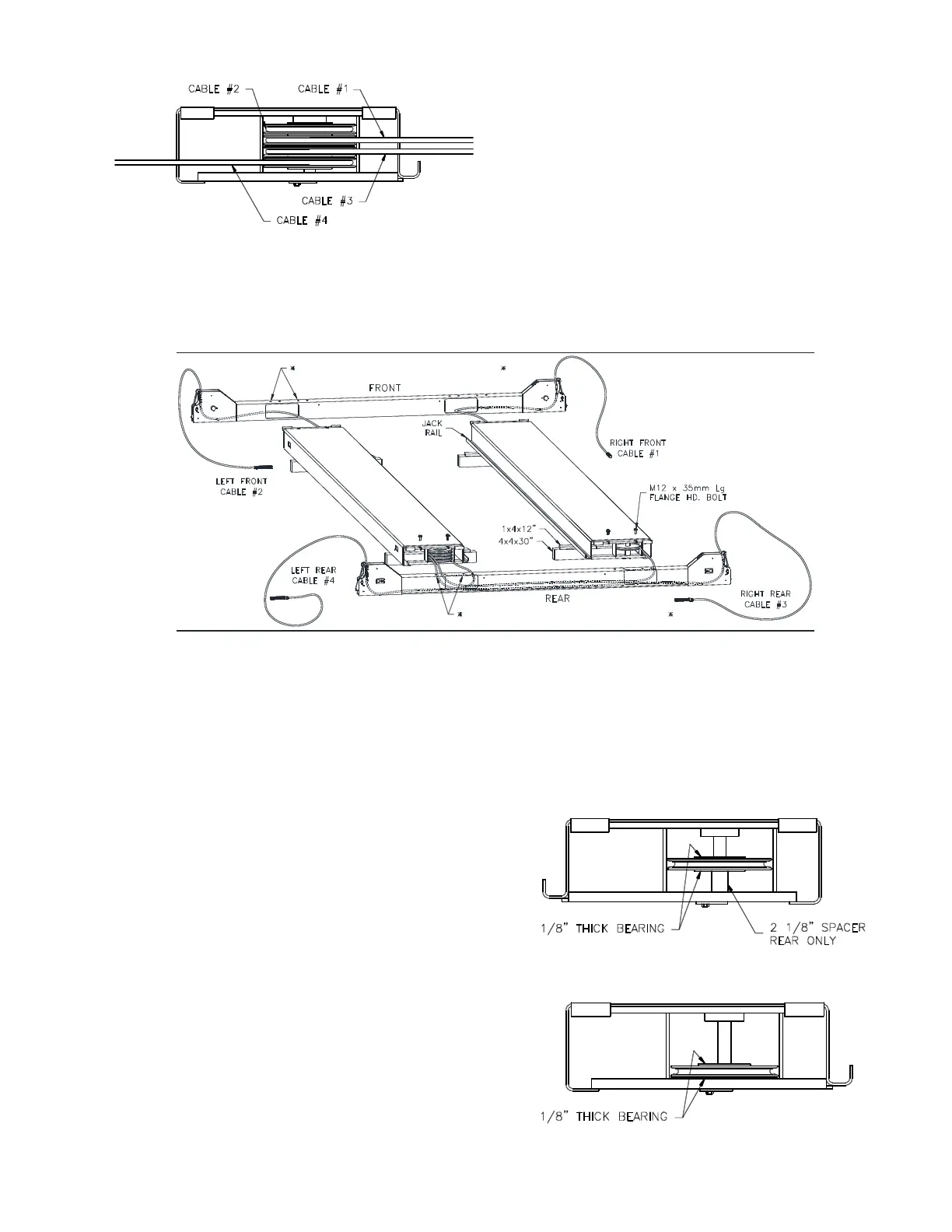

Fig 3 – Power Runway 4-Stack (rear view)

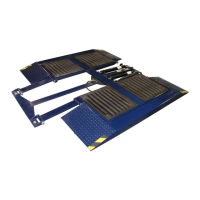

3) Position runways on blocking (see Fig 4) per

layout lines established in step 1. Use four 30”

long 4x4’s spanning the width of the runway and

four 12” long 1x4’s to shim up the jack-rail side

of the runway. Cable #1, #3, & #4 should be

extending out from the rear of the power runway

and cable #2 from the front of the power runway,

Fig 4.

4) Position the front and rear cross beams, Fig 4.

(Both cross beams are identical.)

5) Reach in through either of the access holes in

the cross beam tube and pull out the roll of 4mm

dia. plastic air line connected to the air cylinder

at the end of the cross beam. Repeat for

opposite access hole and position the cross

beam near the end of the runways as in Fig 4.

POWER RUNWAY MUST USE OUTER SET OF HOLES

POWER RUNWAY MUST USE OUTER SET OF HOLES

POWER RUNWAY MUST USE OUTER SET OF HOLES

POWER RUNWAY MUST USE OUTER SET OF HOLES

POWER RUNWAY MUST USE OUTER SET OF HOLES

POWER RUNWAY MUST USE OUTER SET OF HOLES

POWER RUNWAY MUST USE OUTER SET OF HOLES

POWER RUNWAY MUST USE OUTER SET OF HOLES

Fig 4 – Runway Layout

6) Remove the four (4) cross beam sheaves

(one sheave from each end) and the two idler

runway sheaves (also one sheave from each

end). The runway sheave pins do not need

to be removed, just lowered enough to

remove the sheaves.

7) Starting from the bottom of the sheave stack,

route cable #4 through the access hole and

up out the left end of the rear beam. Repeat

for cable #3 out the right end of the rear

beam. Route cable #1 through the access

hole, and back out the idler side access hole.

Look through the idler end of the cross

beam and ensure that cable #1 and #3

have not crossed.

8) Route cable #1 through the idler runway, into

the front cross beam access hole, and out

the right end of the front beam. (Don’t forget

to route it up over the cross-braces in the

bottom of the runway.)

9) Route left front cable #2 through the access

hole and up out the left end of the front

beam.

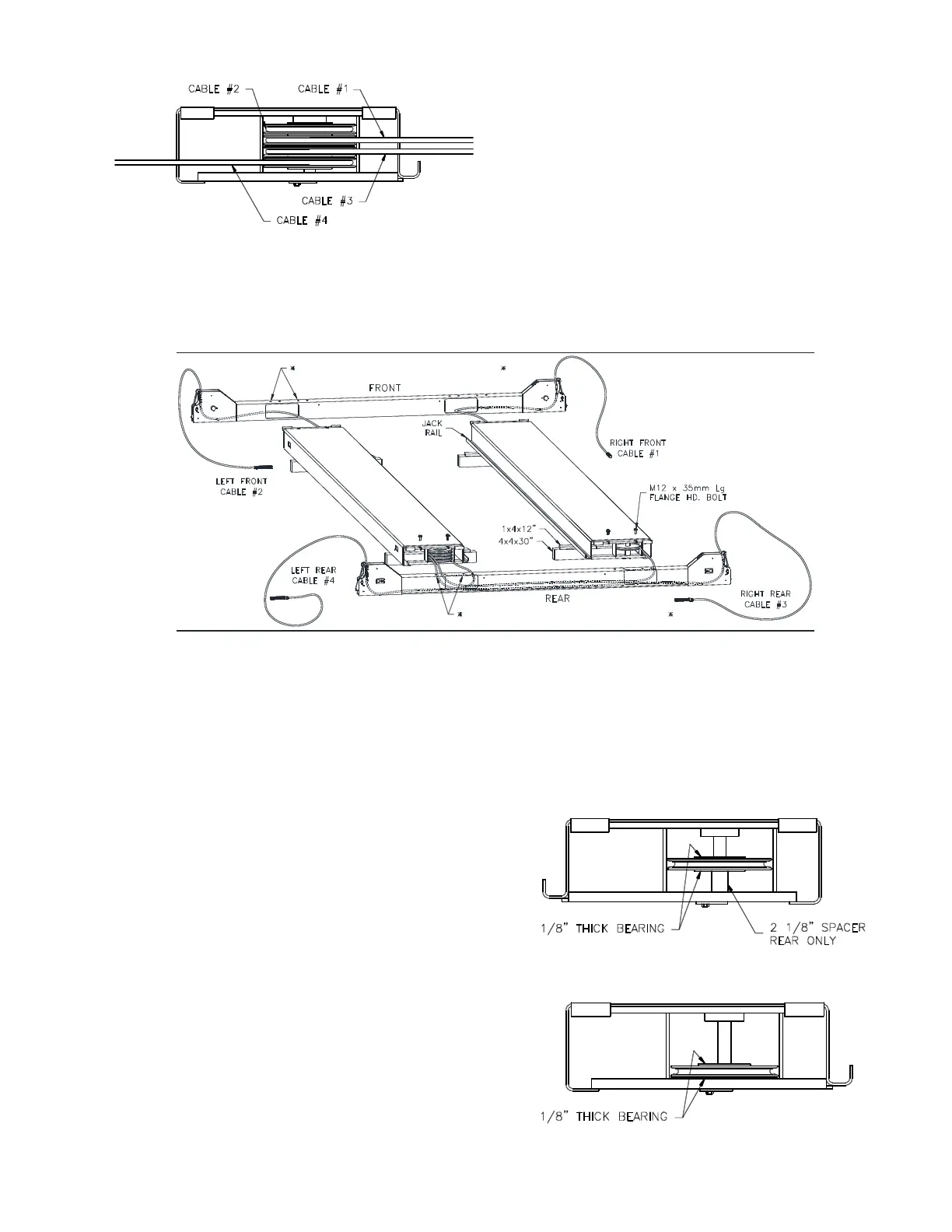

10) Reinstall the cross beam sheaves with one

plastic bearing washer on each side of each

sheave.

11) Reinstall the idler runway sheaves, with one

plastic bearing above and below each

sheave per figures 5 & 6. Note: use one

2 1/8” long spacer at the idler rear sheave

only.

12) Confirm that a 2 1/8” spacer is installed at the

rear of the idler runway and none at the front

of power or idler runways.

Fig 5 – Rear

Single-Stack (idler runway)

Loading...

Loading...