Model 4P14 Flat Deck, Closed Front

Installation, Operation and Maintenance

7 Rev 08/11/17

4P14-X-IOM-A.doc

20) The anchor bolts must be installed at least 8”

from any crack, edge, or expansion joint.

21) Use a concrete hammer drill with a 3/4 inch

carbide bit. Tip diameter should conform to

ANSI Standard B94.12-1977 (.775 to .787).

Do not use excessively worn bits or bits

which have been incorrectly sharpened. A

core bit may be necessary if an obstruction is

encountered. Never substitute with shorter

anchor.

22) Drill the anchor holes using the base plate as

a template. Drill through the floor if possible

or to a depth of 5 inches minimum.

23) Vacuum dust from the hole for proper holding

power.

24) Shim columns to plumb using the shims

provided or steel washers. DO NOT shim

more than 1/2" at any given point. Use a level

no less than 24” in length to plumb columns.

25) Assemble washer and nut to anchor with nut

just below impact section of bolt. Drive

anchor into hole until nut and washer contact

base. Tighten anchor bolts and recheck

column for plumb. Re-shim as required.

26) Torque to 150 foot-pounds to set anchors.

NOTE: Level bubble should not only be

between the lines, the bubble should be

centered

between the lines. If the provided

shims do not allow sufficient centering of the

bubble, it is best to lean the rear columns in

the direction toward each other and the front

columns in the direction toward each other.

27) Install the four cable ends with one flat

washer, one load nut, and one jam nut.

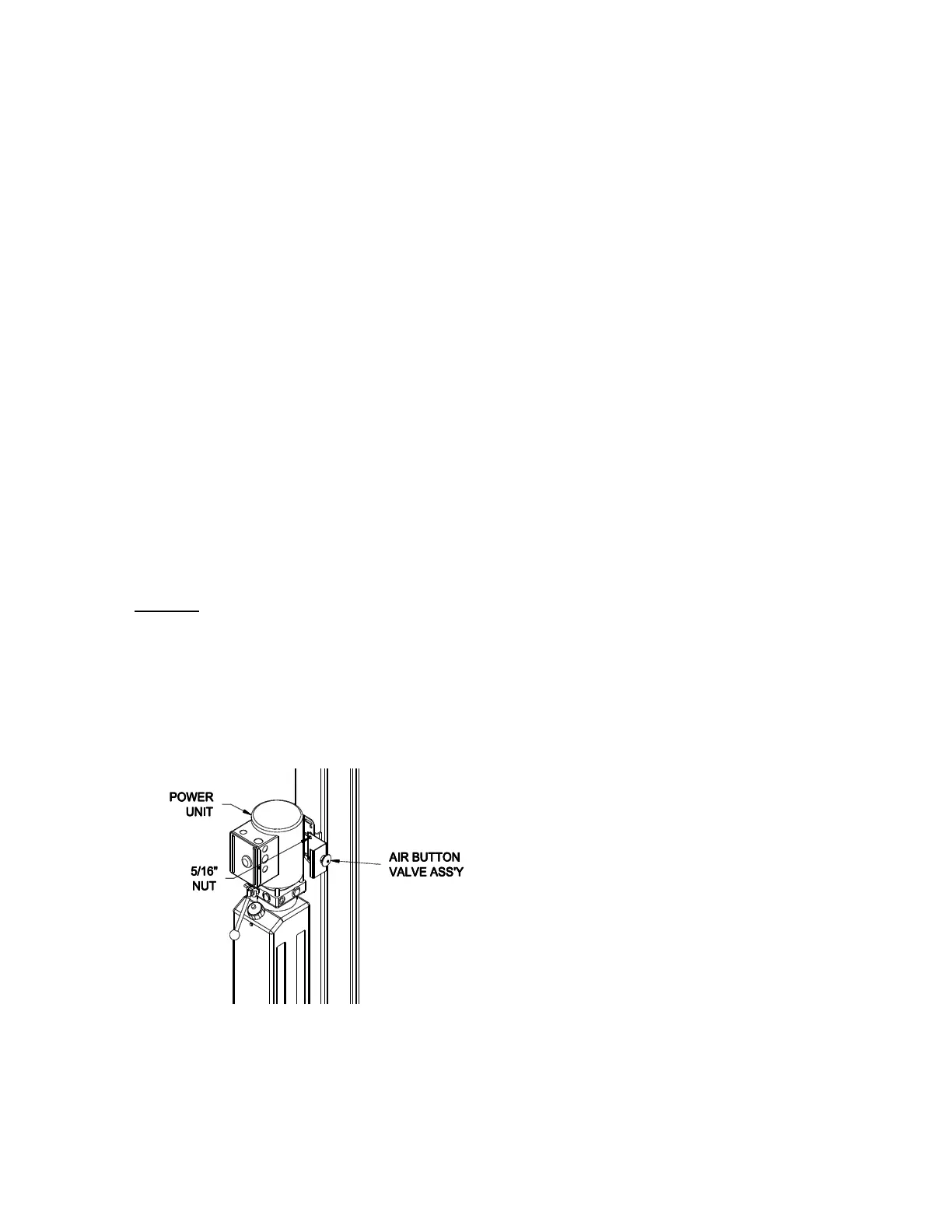

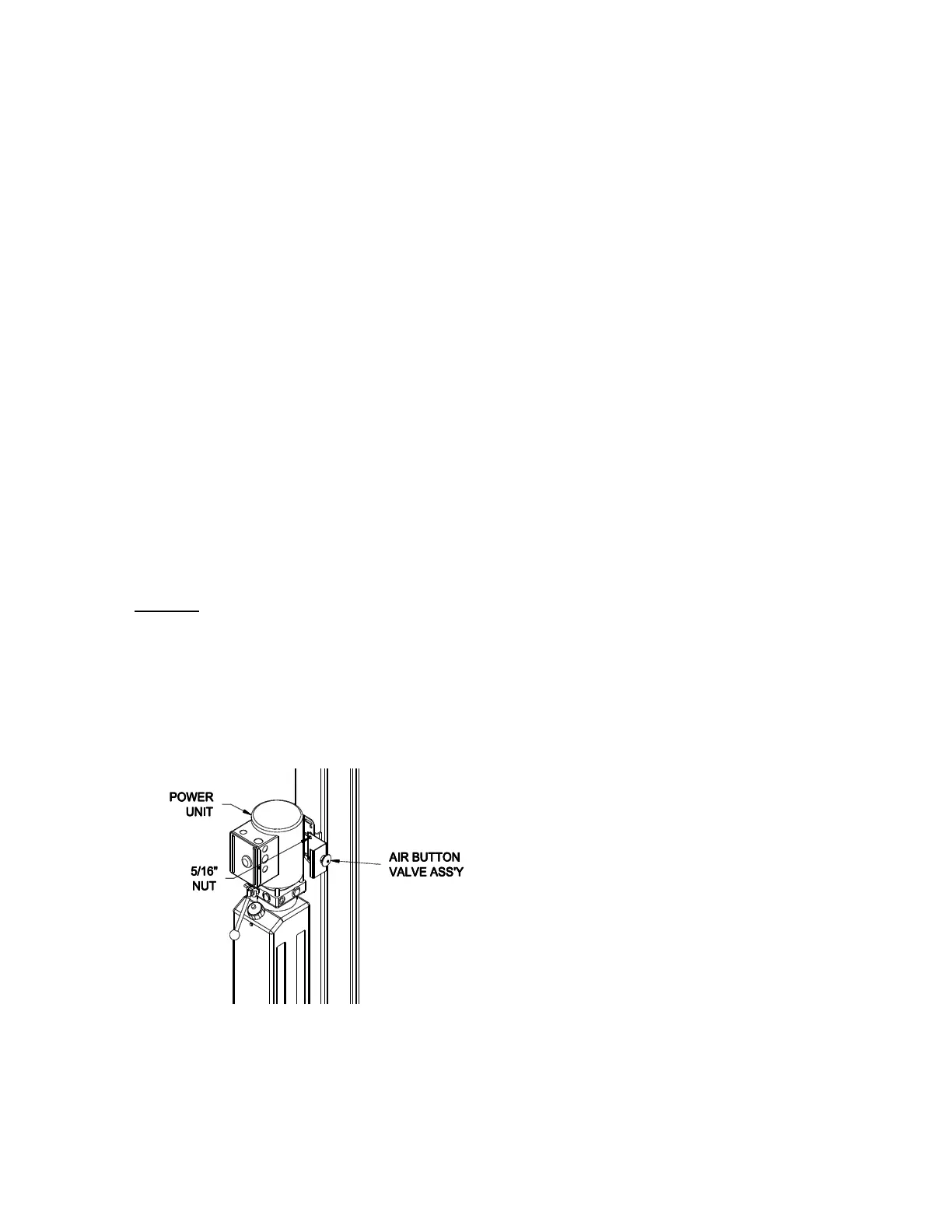

28) Install the power unit and the air button valve

assembly on the power column, Fig 11.

Fig 11 –

Air Button & Power Unit Mounting

29) Install O-Ring end of 90 degree hydraulic

elbow (9/16-18 O-Ring x 37 Male JIC) to

power unit output port. The hydraulic hose is

pre-installed to the hydraulic cylinder and

secured inside the runway. Pull loose end

out through 1 ½” x 4 ½” slot in the side of the

power runway near the power unit and attach

to the elbow fitting.

Do Not Use Teflon Tape or Pipe Dope on

fittings.

30) Have a certified electrician connect the

power unit to a suitable electrical power

source as shown in Fig 16.

Loading...

Loading...