35

C

Mechanical Operators

Symptoms And Solutions

SYMPTOM: The Motor Hums And The Motor Output Shaft Will Not Rotate

POSSIBLE CAUSE: SOLUTION:

Brake did not release (if present) Check the solenoid and check brake adjustment settings.

Door locked or jammed Check door.

Dead phase Check the power supply.

Brake may not be disengaging when starting

relays energize (if present)

Manually disengage and test again. Repair if needed.

SYMPTOM: Door Will Not Move In Either Direction

POSSIBLE CAUSE: SOLUTION:

Clutch is loose Adjust the clutch.

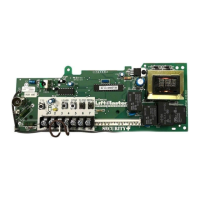

The pulley V-belt is loose Adjust belt by adjusting motor position.

The drive chain has broken Replace drive chain.

Manual disconnect may be engaged Disengage the disconnect.

SYMPTOM: Door Travels In One Direction Only

POSSIBLE CAUSE: SOLUTION:

Bad or miswired limit switch Test continuity of switches and replace as needed. Verify wiring with

schematic provided.

Bad or miswired 3-button control station Rewire or replace control station.

Open or close relay miswired or defective Rewire or replace relay.

SYMPTOM: Motor Hums And Starts When It Is Spun

POSSIBLE CAUSE: SOLUTION:

Faulty centrifugal start switch (no start switch

on 1/3 and 1/2 HP motors using Logic 2.0)

Tap the motor; if it runs now, the centrifugal switch may be faulty –

replace the motor.

Faulty capacitor Replace capacitor.

SYMPTOM: Motor Does Not Hum Or Run In Either Direction

POSSIBLE CAUSE: SOLUTION:

Motor thermal overload tripped Let the motor cool down so internal overload can reset itself, or press

the reset depending on model.

Power is not connected properly Check terminals, circuit breaker, fuses and electrical service panel.

Open and close limit switches are activated Check limit switches.

Control station wired wrong, or has a stuck

button, or auxiliary device is not functioning

properly

Check continuity from common to NC prongs. Readjust or replace

switches. Remove control stations and auxiliary devices. Test the

operator by jumping T4 and T3, then cross T3 and T1 to open T3 and

T2 to close. Reattach items one at a time and test operation between

each component installation using the component of low-

voltage control wires. Replace, repair, or rewire non-working devices.

Bad start switch in motor (single phase only) Check across black wires on coil of IR relay. Should read same as line

voltage.

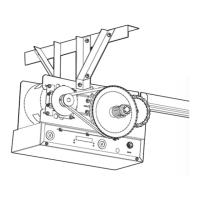

SYMPTOM: Jackshaft Or Hoist Operator Makes Clicking Noise

POSSIBLE CAUSE: SOLUTION:

External interlocks Interlocks must be “normally closed”. Check switch and wiring.

Miswired motor Verify the motor is wired correctly

The operator is mounted wrong; the drive

sprockets are not in line with the driven

sprockets and the chain is clicking

Reposition the operator.

Loading...

Loading...