36

C

Mechanical Operators

Symptoms And Solutions

SYMPTOM: Door Drifts After The Operator Is Shut Off

POSSIBLE CAUSE: SOLUTION:

Brake needs adjusting (if present) Check and adjust brake.

Door poorly balanced Check and adjust door/springs.

SYMPTOM: Door Travels Down And Then Stops And Reverses

POSSIBLE CAUSE: SOLUTION:

A sensing device is being activated Check wiring of the sensing device.

Radio receiver may be sending a long signal

to the operator; this can cause the operator

to travel down off the open limit, then reverse

again

Try disconnecting the receiver. If the problem disappears, use a

LiftMaster Brand Receiver

SYMPTOM: Door Opens And Then Stops Short Of The Full Open Position

POSSIBLE CAUSE: SOLUTION:

Limit nut not set correctly Adjust limit nut.

An obstruction may be preventing the proper

operation of the door

Check door for obstruction.

The clutch may need adjustment Check the sensitivity of the clutch.

Defective limit switch activating prematurely Check limit switch; replace if necessary.

SYMPTOM: Operator Does Not Open Or Close In Response To Command From 3-Button Control Station

POSSIBLE CAUSE: SOLUTION:

Bad wire to 3-button control station Recheck wiring.

Circuit breaker has tripped Reset circuit breaker.

Damaged transformer Check transformer and circuit for 24V.

If equipped with electric interlock, there may

be a poor contact to the interlock switch

Verify all interlock switches are working correctly and wiring is

making good contact.

Blown fuse Replace fuse.

SYMPTOM: The Door Will Not Close Completely

POSSIBLE CAUSE: SOLUTION:

The limit assembly depression plate is not

properly engaged with nylon limit nut

Check and adjust if necessary.

The door is binding or meeting an obstruction Look for obstruction.

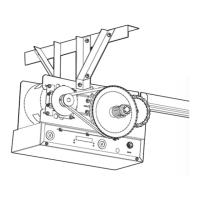

Loose drive or limit chain can cause the chain

to “jump” the sprocket teeth

Check the chain as necessary. The limit chain can be adjusted/

tensioned at the electrical box assembly via two mounting screws.

SYMPTOM: Motor Runs In Wrong Direction

POSSIBLE CAUSE: SOLUTION:

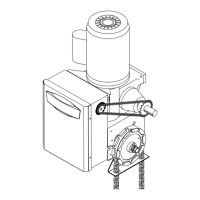

Operator is upside down For MJ, install operator with motor toward the ceiling. For MT,

the electrical box and motor should be toward the floor. Correct if

necessary.

Motor is wired incorrectly Check and correct wiring.

Three-phase wires are in the wrong order Rearrange any two incoming three-phase power legs on the

terminal strip.

Loading...

Loading...