Now with

Built in

Radio Receiver

315 MHz

Now with

Built in

Radio Receiver

315 MHz

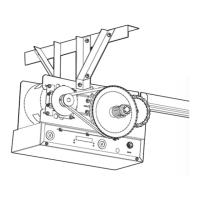

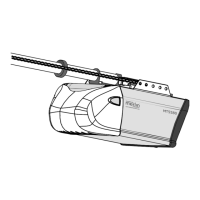

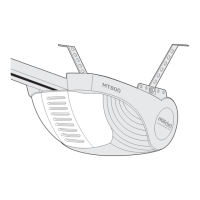

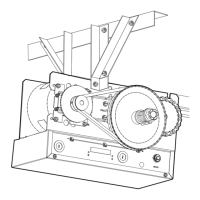

MEDIUM DUTY DOOR OPERATOR

MODELS MT5011U & BMT5011U

INSTALLATION MANUAL

NOT FOR RESIDENTIAL USE

Your model may look different than the model illustrated in this manual.

THIS PRODUCT IS TO BE

INSTALLED AND SERVICED BY A

TRAINED DOOR SYSTEMS

TECHNICIAN ONLY.

Visit www.liftmaster.com to locate a

professional installing dealer in your area.

OPERATOR RATING: 12 cycles per hour,

50 cycles per day; maximum

Serial #

(located on electrical box cover)

Installation Date

2 YEAR WARRANTY