25

CONDITION POSSIBLE CAUSE FIX

OPERATOR WILL NOT

RESPOND TO ANY

COMMANDS

A) No power

➤ Verify primary line voltage (120 Vac, 60 Hz) is present at terminals L1 & L2.

The LED will fl ash when power is present.

B) Stop circuit not complete

➤ Verify Stop Button input (terminals 3 & 5) is properly wired and stop button is

not stuck.

C) Stuck button on 3-button

control station

➤ Verify that all buttons are actuating freely and releasing properly.

D) Interlock input activated ➤ Verify jumper is located at terminals 3 & 4 if interlock is not present.

➤ Verify interlock is properly wired and not activated.

E) Motor overload tripped ➤ Overload is internal within motor. Allow to cool and retry.

F) Accessory failure

➤ Attempt to close by holding the CLOSE button for more than 5 seconds. If door

closes, check accessory for proper wiring, polarity, connections or damage.

➤ Verify photoelectric sensors are aligned or sensing edge is not activated.

G) Possible component failure ➤ Call Technical Support for assistance.

OPERATOR MAKES

NOISE BUT DOOR DOES

NOT MOVE

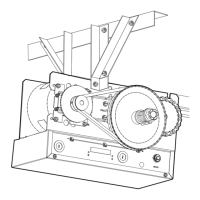

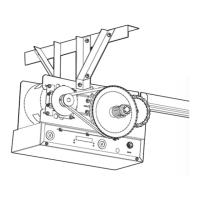

A) Clutch slipping ➤ Adjust clutch, see ADJUSTMENT section.

B) Brake not releasing (if present) ➤ Verify brake assembly operation and wiring.

C) Door operation problem ➤ Disconnect trolley and check door for proper operation.

OPERATOR MOVES IN

THE WRONG DIRECTION

OPEN and CLOSE button wiring

connection reversed

➤ Check 3-button control wiring.

DOOR DRIFTS AFTER

OPERATOR STOPS

A) Door not balanced properly ➤ Disconnect trolley assembly and check door for proper operation.

B) Clutch slipping ➤ Adjust clutch, see ADJUSTMENT section.

C) Brake not functioning properly

➤ Check brake mechanism to ensure brake lever is free and brake pads are

engaging the brake disc.

DOOR OPENS/CLOSES

TOO FAR

Limits not adjusted properly ➤ Adjust limits. See ADJUSTMENT section.

DOOR REVERSES

UNEXPECTEDLY

Intermittent Entrapment Protection

Device activation

➤ Check all connections.

TTC NOT FUNCTIONING

A) Monitored Entrapment

Protection Devices

➤ Check all connections. Verify photoelectric sensors are not blocked and the

sensing edge is not activated.

B) TTC temporarily disabled ➤ Close and Open the door. TTC will be re-enabled.

C) TTC not programmed properly ➤ Reprogram TTC. See PROGRAMMING TTC section.

RADIO FUNCTIONALITY NOTE: Built in radio receiver compatible with all LiftMaster 315 MHz remote control devices.

NO RESPONSE

A) Remote control is not

programmed

➤ See PROGRAMMING REMOTE CONTROLS section.

B) Remote control not compatible ➤ Obtain qualifi ed LiftMaster remote control device.

C) Low battery ➤ Replace battery.

REMOTE CANNOT BE

LEARNED

A) Low battery ➤ Replace battery.

B) Remote control not compatible ➤ Obtain qualifi

ed LiftMaster remote control device.

POOR RADIO RANGE

A) Low battery in remote ➤ Replace battery.

B) Antenna not confi gured ➤ See SETUP RADIO ANTENNA.

C) Ambient radio interference or

building structural issue

➤ Use EXTERNAL ANTENNA kit (see ACCESSORIES page).

Technical Support 1-800-528-2806

TROUBLESHOOTING

Loading...

Loading...