advanced identification and correction strategy such as enrich air/fuel mixture shall be

adapted to reduce ignition advance angle.

Operational theory: Knock sensor consist of piezoelectric non-resonant quartz and

converts electric signal into mechanical energy in form vibrations. The sensor is

connected to engine ECU through a shielded wire. When knock occurs, ECU will receive

peak values of high-energy signal, which is discriminable from normal combustion signal.

During knocking, air/fuel mixture shall accordingly enrich to ensure exhaust temperature is

within the safe specification when appropriate reducing of ignition advance angle is needed,

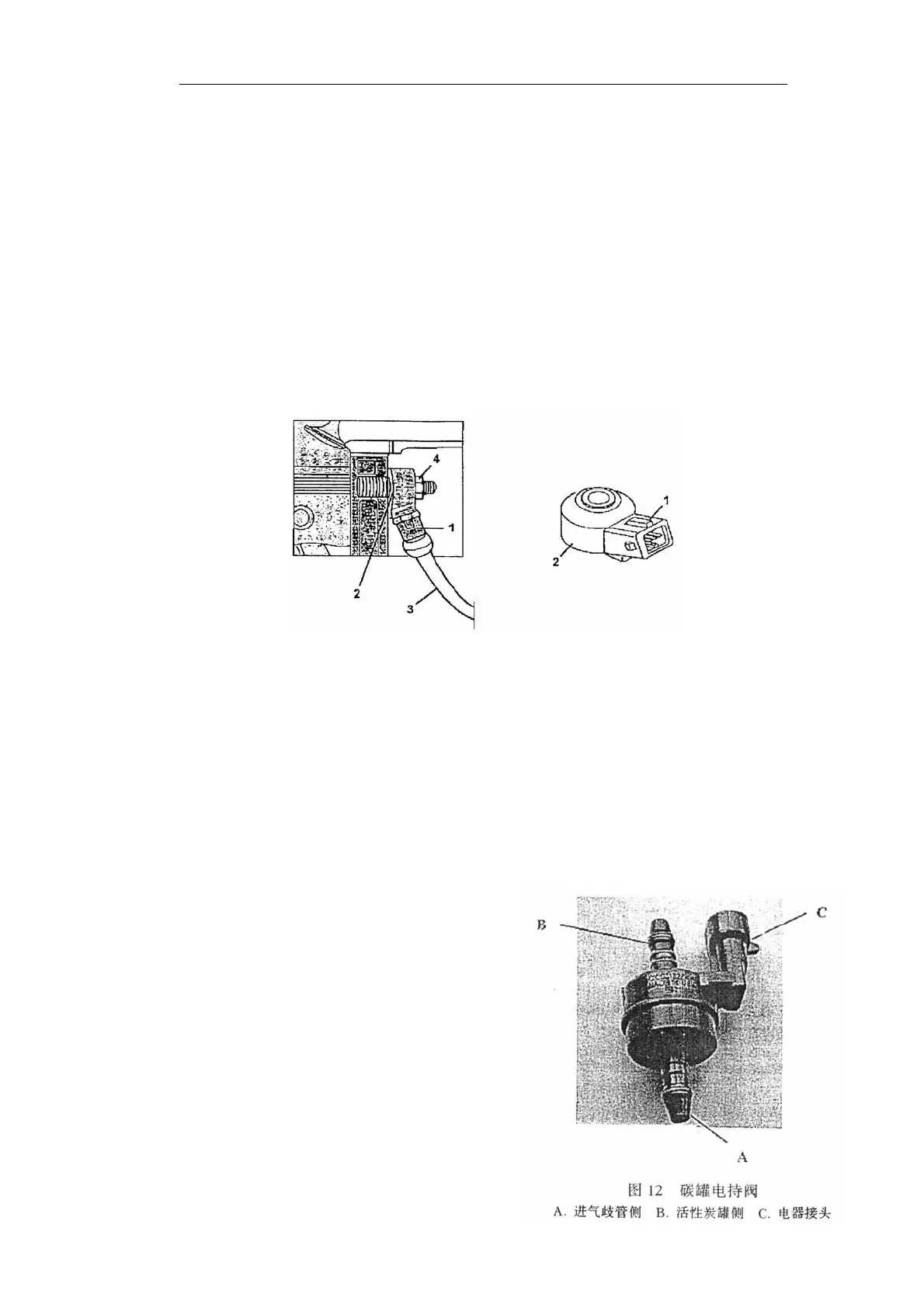

The knock sensor is installed on the cylinder body between cylinder2 and cylinder3,

on the side of intake manifold. Tighten torque is 19.6±4.9Nm. USE SPECIAL CARE to

this torque specification.

5. Preventing fuel from evaporating and fuel vapor recycle system

By this system, fuel vapor formed in fuel tank and fuel feed system is combusted in engine

combustion chamber after filtering, prevent fuel vapor from being exhausted into

atmosphere.

(1) Active carbon canister

Active carbon canister is used for absorbing and storing fuel vapor in fuel tank and fuel

vapor is then transferred into air intake manifold through carbon canister control solenoid.

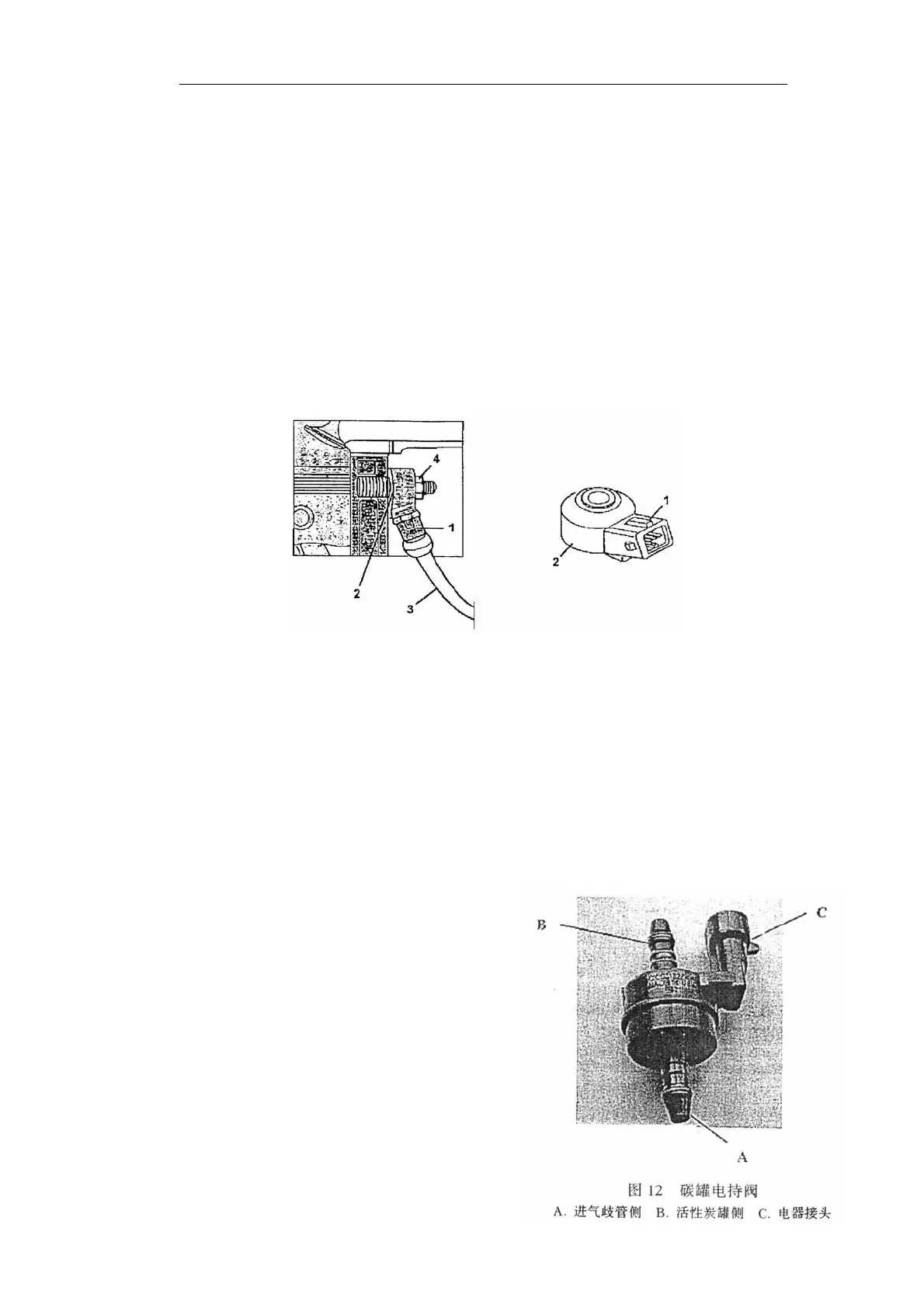

(2) Carbon canister solenoid

Under the control of ECU, carbon canister

solenoid has the following functions:

1. When ngine stop running and under stop

condition, carbon canister solenoid prevent

fuel vapor in fuel tank from entering air intake

manifold. When ignition key is turned to MAR

position, closed carbon canister solenoid will

start to work. l start to work.

2. At the stage of engine start-up, carbon canister

keep closed to prevent fuel vapor over enriching

air/fuel mixture, which will last till engine

Fig 11 Konck Sensor

1. Knock sensor connector 2. Knock sensor 3. Sensor wiring 4. locking nut

Loading...

Loading...