Maintenance Manual for Chery·Windcloud M7.9.7 EFI System

4. Knock Sensor KS

Purpose: this sensor is designed to provide

ECU with engine knocking information so

as to carry out knocking control.

Composition and principle: knock sensor

is a sort of vibration acceleration sensor,

which is fixed on engine cylinder block.

ECU controls engine ignition via signals

detected by pressure-sensing element.

Failure diagnosis: ECU monitors on

various sensors, actuators, power

amplification circuits and sensing circuits. In

case any of the following situations occurs,

failure mark of the knock sensor is set.

Knock sensor failure

Knocking control data processing circuit

failure

Cylinder-detecting signal is unreliable

After failure mark of knock sensor being set,

knocking closed-loop control is shut down,

reduceing a safety angle from the ignition

advance angle stored in ECU. When error

frequency cuts down to below setting value,

failure mark restores.

Installation hint: tightening torque is

20±5Nm.

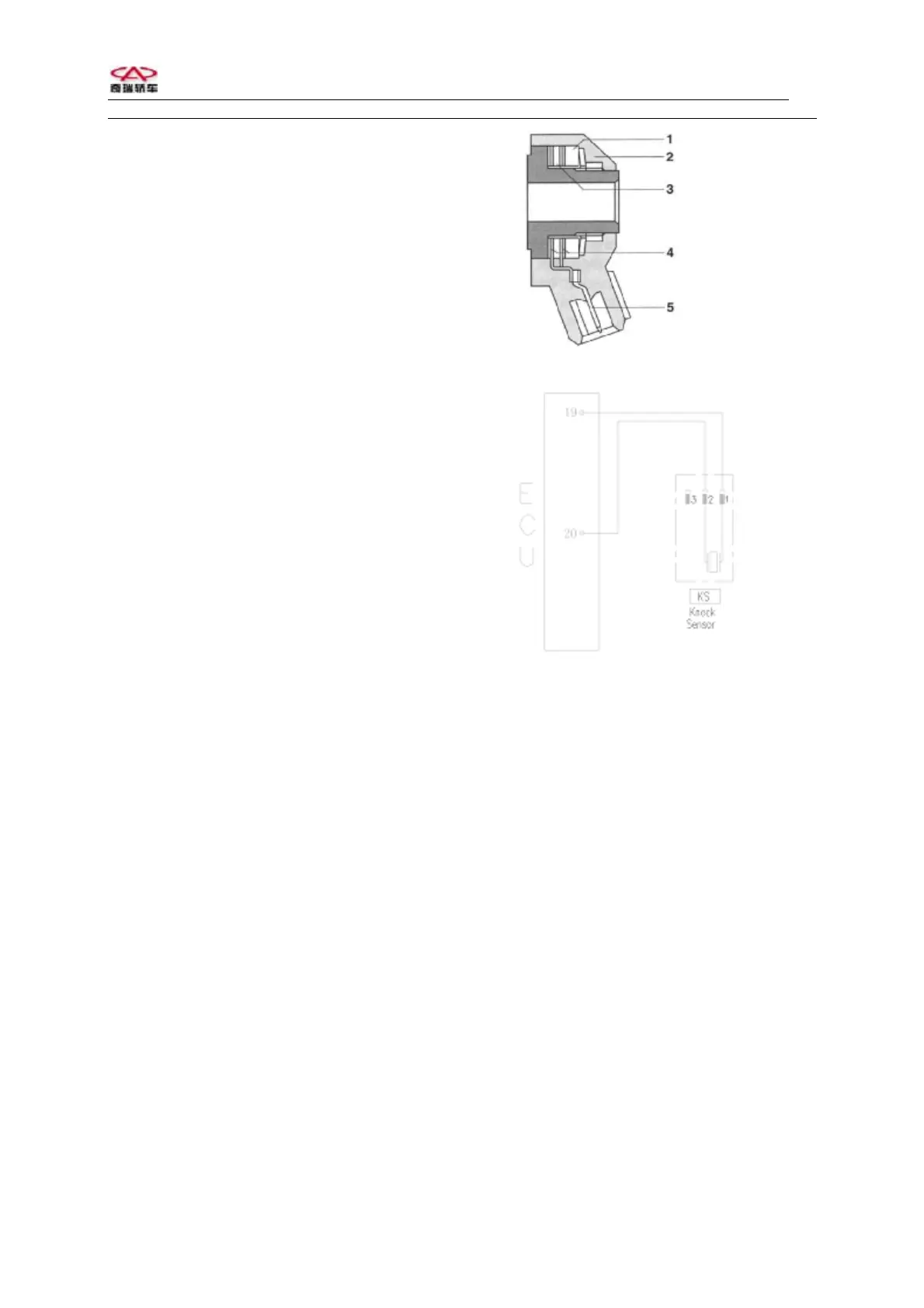

Knock sensor with cable

1.

noc

ing bloc

2. Casing

3. Piezoelectric ceramics

4. Contactor

5. Electric connection

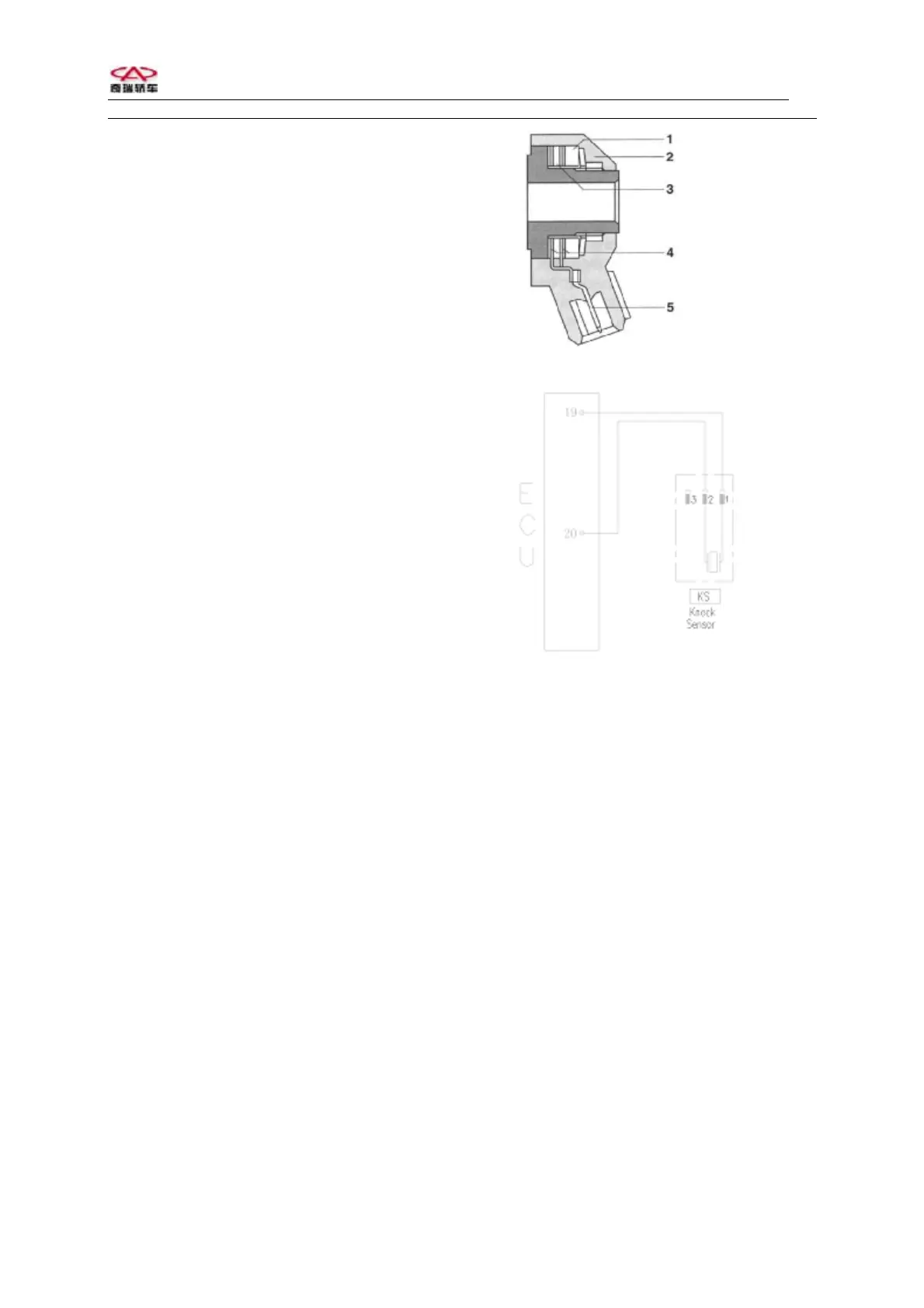

Circuit diagram of knock sensor

Pins:

1 Knock sensor signal 1 (ECU19#)

2 Knock sensor signal 2 (ECU20#)

Troubleshooting: mainly check if there is

short circuit or open circuit on the

connection between 2 lines on senosr and

corresponding ECU pins.

If gasket is added during installation; if

tightening torque is proper.

If there is stitching defect between sensor

and cylinder, or there is foreign matter

between them.

4

Loading...

Loading...