Model 108 FLEX-AUGER Installation Manual

in the instructions on page 54.

C. Use a small screw driver to remove the caulk concealing the

Sensitivity Adjustment Screw (see figure below).

D. IMPORTANT: A Proximity Switch may be used in a feed bin

boot to shut the fill system down when it no longer senses

feed.

A Proximity Switch may also be used as a feed level switch

at the control end of the line. In this application the switch is

used to shut the system down when it senses feed.

Before adjusting the Proximity Switch, carefully consider

how you want the switch to react when it senses feed. For

addition information, see the instructions shipped with the

Proximity Switch.

Greater switch sensitivity is achieved by turning the Sensi-

tivity Adjustment Screw clockwise.

Less switch sensitivity is achieved by turning the Sensitivity

Adjustment Screw counterclockwise.

Note the screw orientation before beginning adjustment.

Adjust the Sensitivity Adjustment Screw 1/4 turn, test

switch, continue adjusting as required.

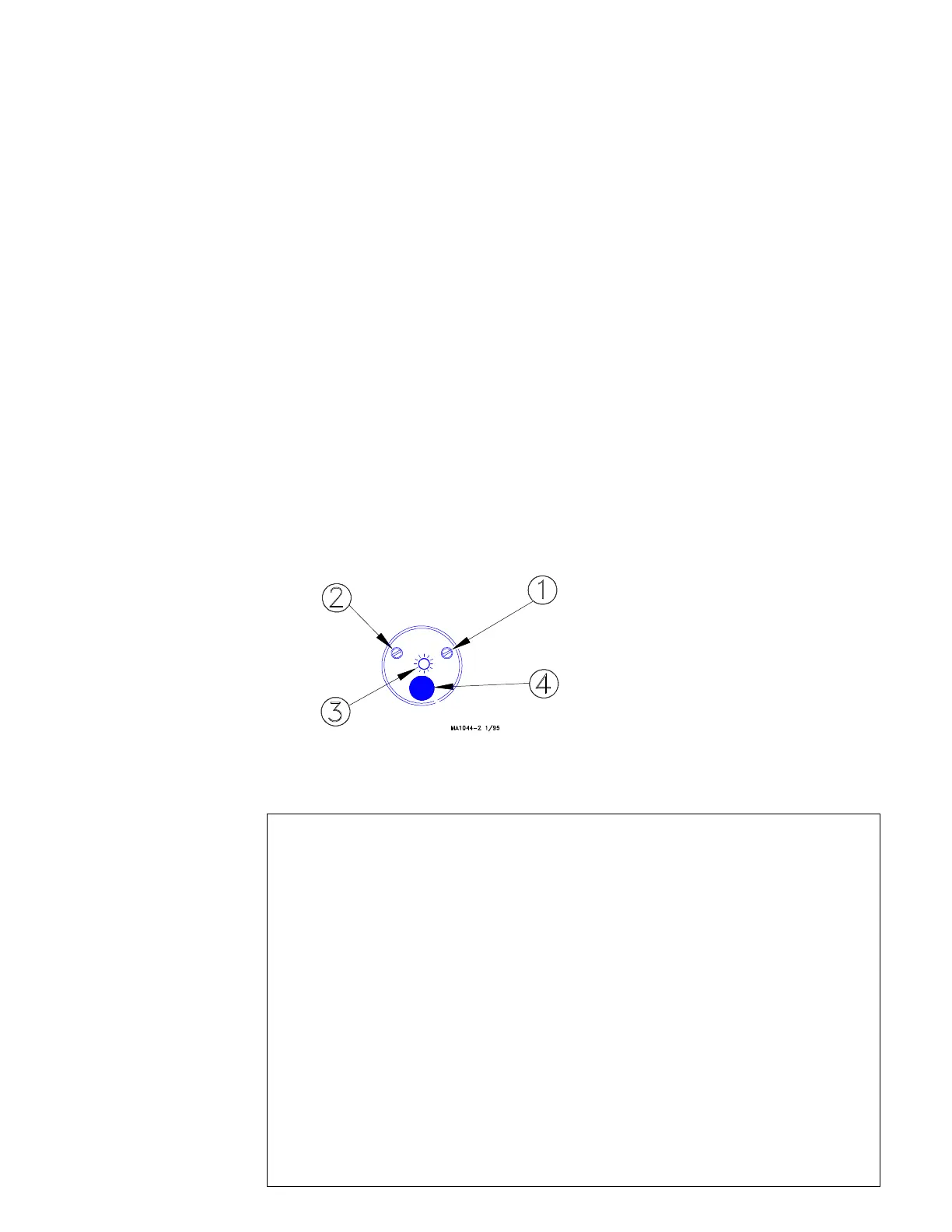

Proximity Switch (End View)

Key Description

1 Sensitivity Adjustment Screw

2 Delay Adjustment Screw

3 Indicator Light

4 Power Cord

10. Discard damaged or replaced equipment according to local

and national codes. Many of the components may be recy-

cled.

Cementing the PVC Auger Tube

The auger tubes and elbows for the FLEX-AUGER systems are made of special-

ly formulated PVC tubing. Use the PVC solvent cement to make strong, reliable

bonds.

FOLLOW DIRECTIONS ON THE CAN FOR SAFE HANDLING OF CEMENT.

1. Be sure tube is cut off squarely. Remove burrs from outside and inside the

end of the tube.

2. Dry fit all parts. Tube should fit inside belled end of next tube to full depth

without excess force.

3. Clean surfaces to be joined. SURFACES MUST BE FREE OF DIRT OR

GREASE!

4. Apply a generous coat of cement to both the inside of the belled end and

outside of the other tube. Be sure cement covers all of the joint area so

there are no bare spots.

5. Quickly join the tubes, giving them a twisting motion to bring them into

alignment as they are joined.

6. Keep pressure on the joint until the PVC cement sets up.

Loading...

Loading...