WELDSKILL 100, 135, 150 MIG

3-9

Installation

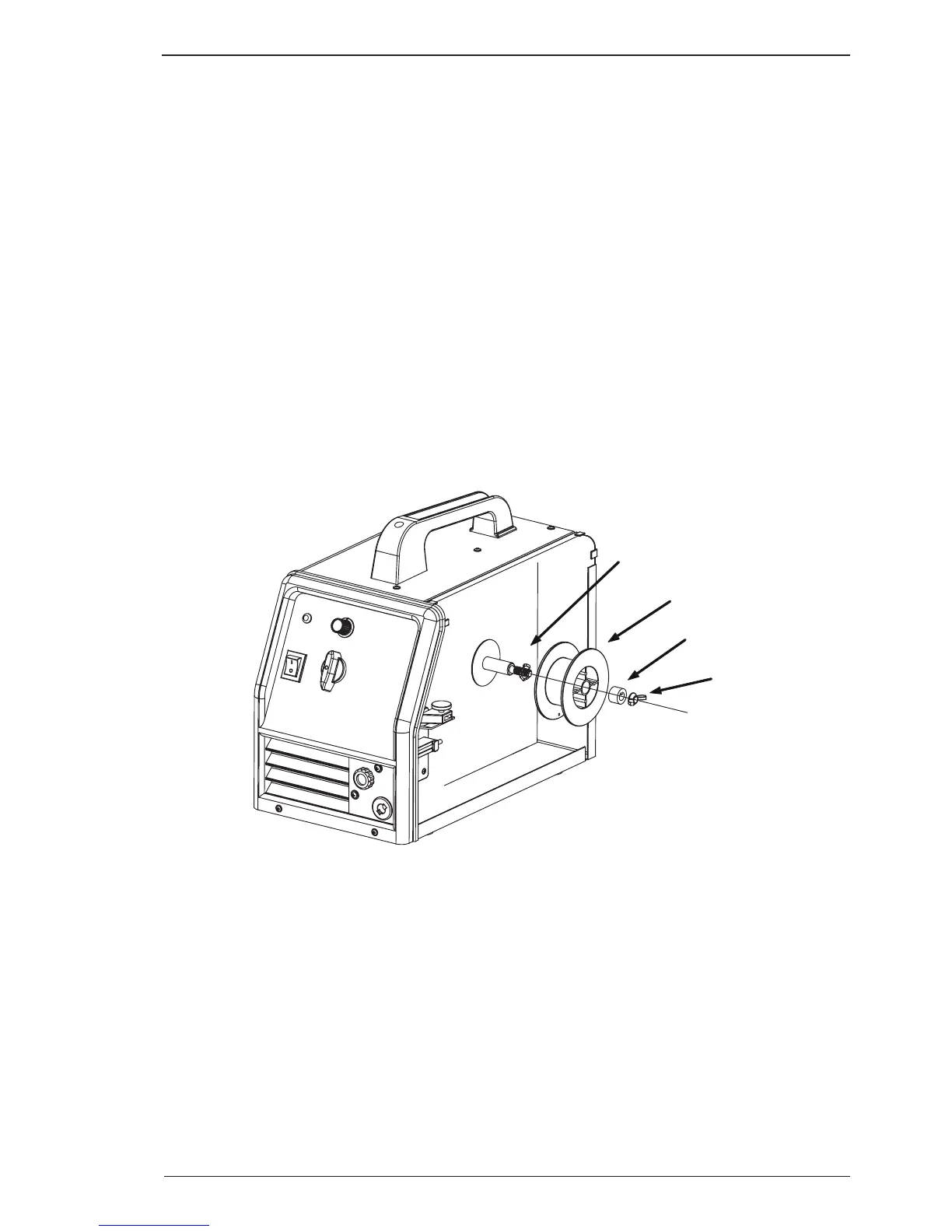

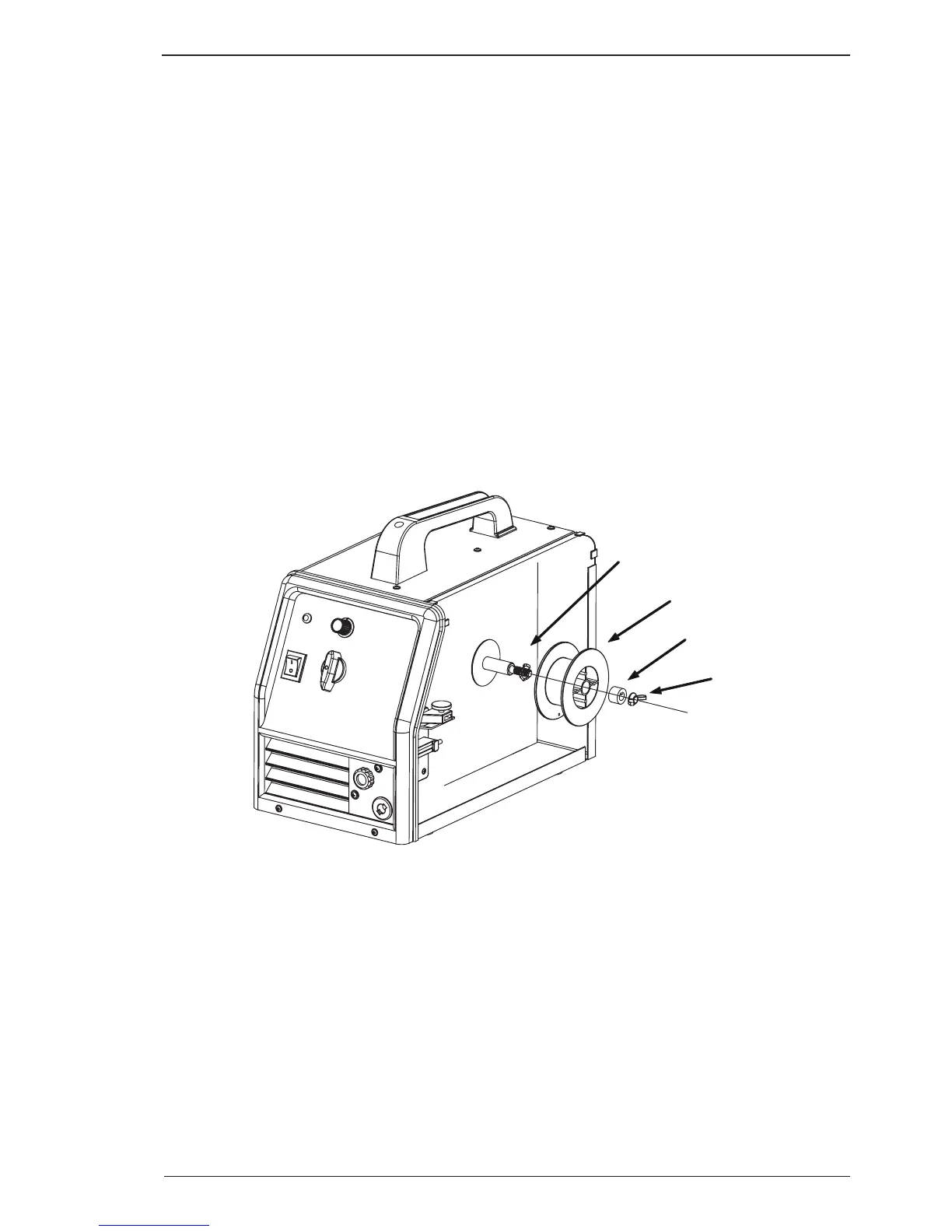

3.12 Installing Minispool (100mm diameter) – WeldSkill 135 and 150 MIG

As delivered from the factory, the unit is set for a Minispool (100mm diameter).

Assemble parts in sequence shown below in figure 3-9.

1. Friction Washer

2. Minispool

3. Spacer

4. Wingnut

Adjustment of this wingnut will control the Mig Wire Spool Brake. Clockwise rotation of the wingnut

tightens the brake. The Brake is correctly adjusted when the spool stops within 10 to 20mm (measured

at the outer edge of the spool) after Mig Torch trigger is released. Wire should be slack without becom-

ing dislodged from the spool.

Friction Washer

Minispool

Spacer

Wingnut

Art # A-09004

Figure 3-9: 100mm Spool Installation

Loading...

Loading...