WELDSKILL 100, 135, 150 MIG

4-3

Operation

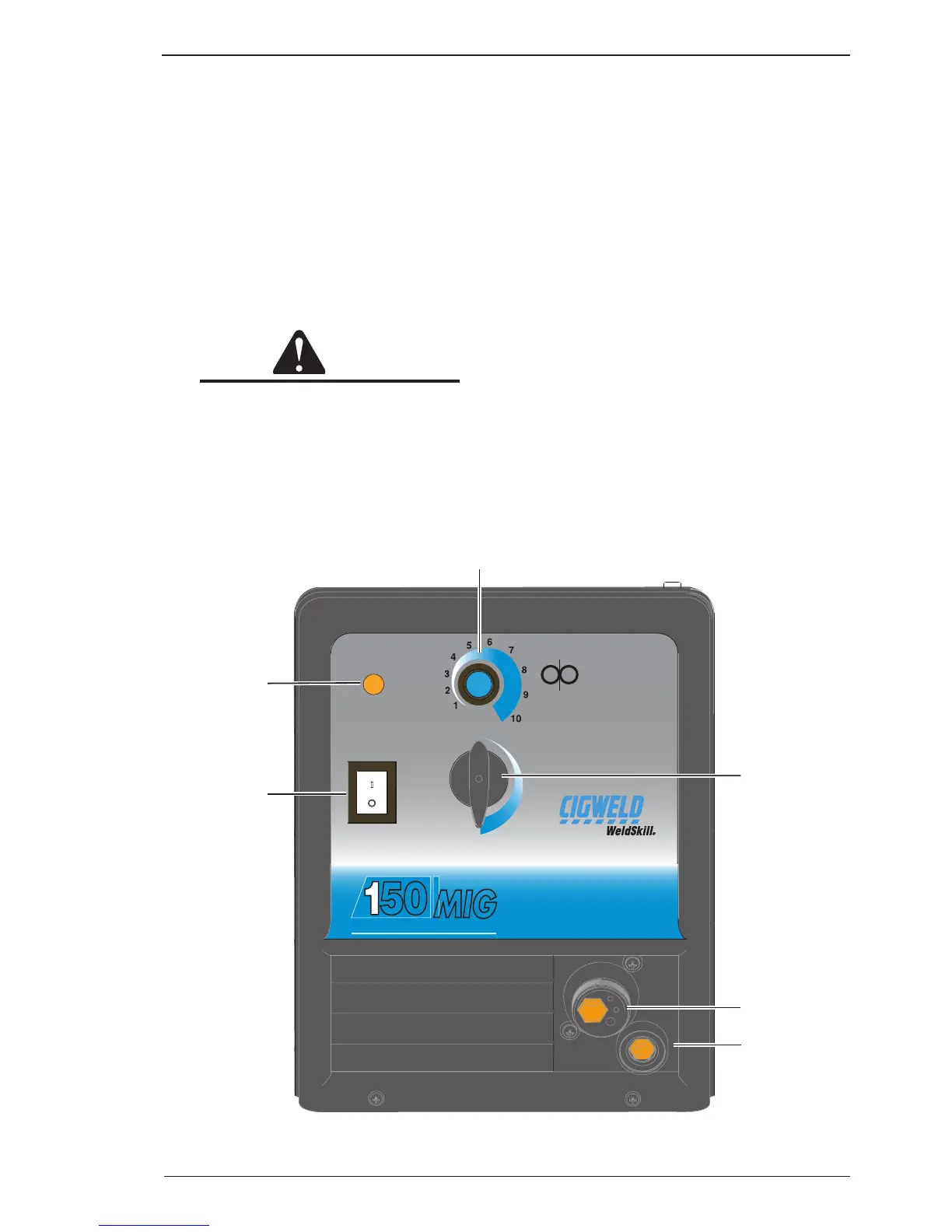

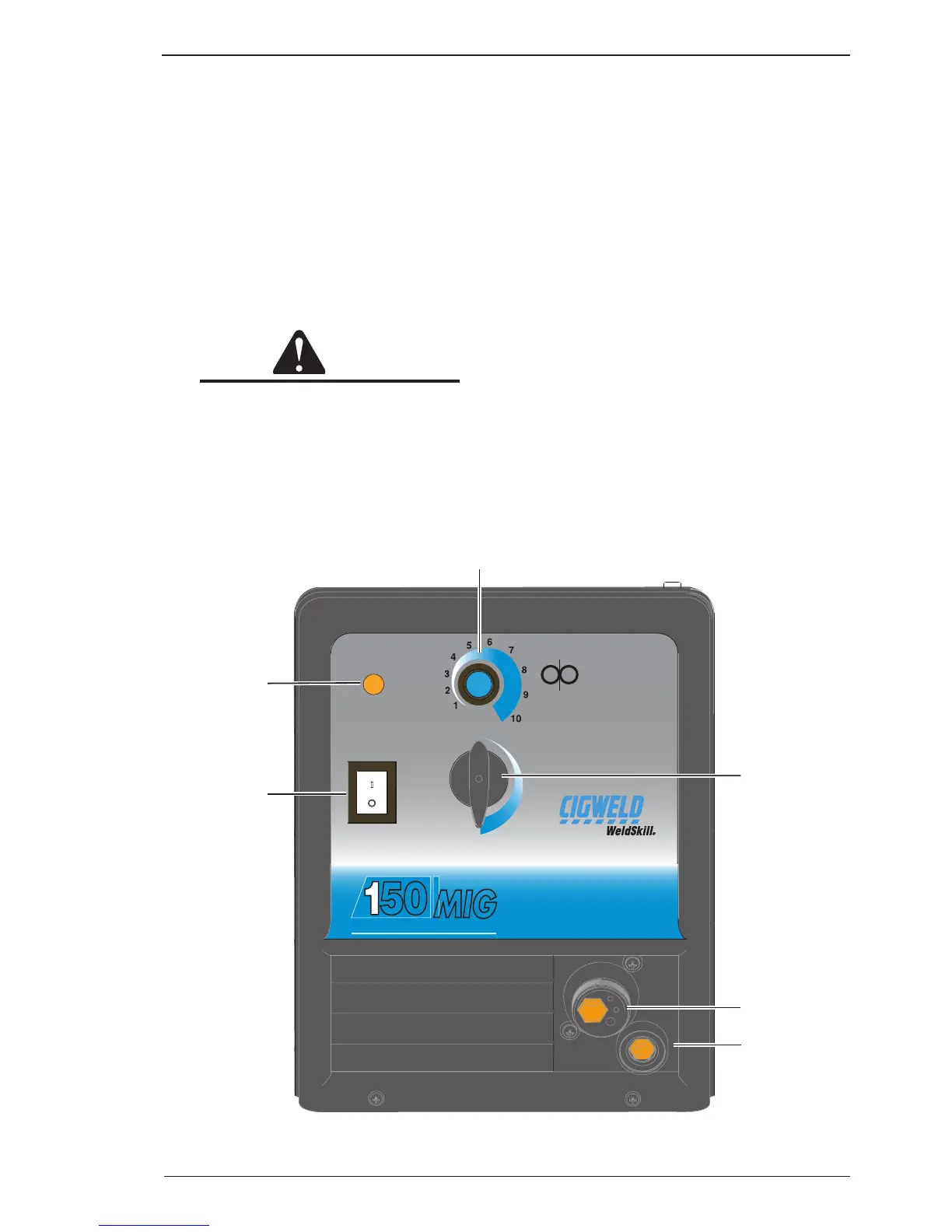

4.03 WeldSkill 150 Mig Power Source Controls, Indicators and Features

A. Wirespeed Control

The Wirespeed Control knob controls the weld-

ing current via the electrode wire feed rate which

determines the speed of the wire feed motor.

B. Output Voltage Control Switch

The Output Voltage Control Switch sets the volt-

age level to the welding terminals as it is rotated

in the clockwise direction. There are 4 positions

available. The OFF switch position disconnects the

power from the controls.

CAUTION

The Output Voltage Control Switch MUST

NOT BE SWITCHED during the welding

process. Some internal electrical compo

-

nents are at Mains voltage potential with

this switch in the OFF position.

C. MIG Torch Connection (Euro)

Fit the MIG Torch to the Power Source by pushing

the torch connector into the torch adaptor and

screwing the plastic torch nut clockwise to secure

the torch to the torch adaptor.

D. Work Cable and Clamp Port Dinse Connector Socket

The work cable and clamp are routed through this

opening.

E. Control On/Off Switch with in-built Indicator Light

The Control On/Off Switch Indicator illuminates

when the Control On/Off switch is in the On position

and the correct mains voltage is present.

F. Over Heat Indicator

The Power Source is protected by a self resetting

thermostat. The Indicator will illuminate and weld-

ing current ceases if the duty cycle of the power

source has been exceeded. If the Over Heat Indica-

tor Illuminates wait for the Over Heat Indicator to

extinguish before resuming welding.

Loading...

Loading...