0-5461 6-5 OPERATION

6.03 TIG (GTAW) Basic Welding Technique

Gas Tungsten Arc Welding (GTAW) or TIG (Tungsten Inert Gas) as it is commonly referred to, is a weld-

ing process in which fusion is produced by an electric arc that is established between a single tungsten

(non-consumable) electrode and the work piece. Shielding is obtained from a welding grade shielding gas

or welding grade shielding gas mixture which is generally Argon based. A filler metal may also be added

manually in some circumstances depending on the welding application.

Non-Consumable

Art # A-09658_AC

Figure 6-4: TIG Welding Application Shot

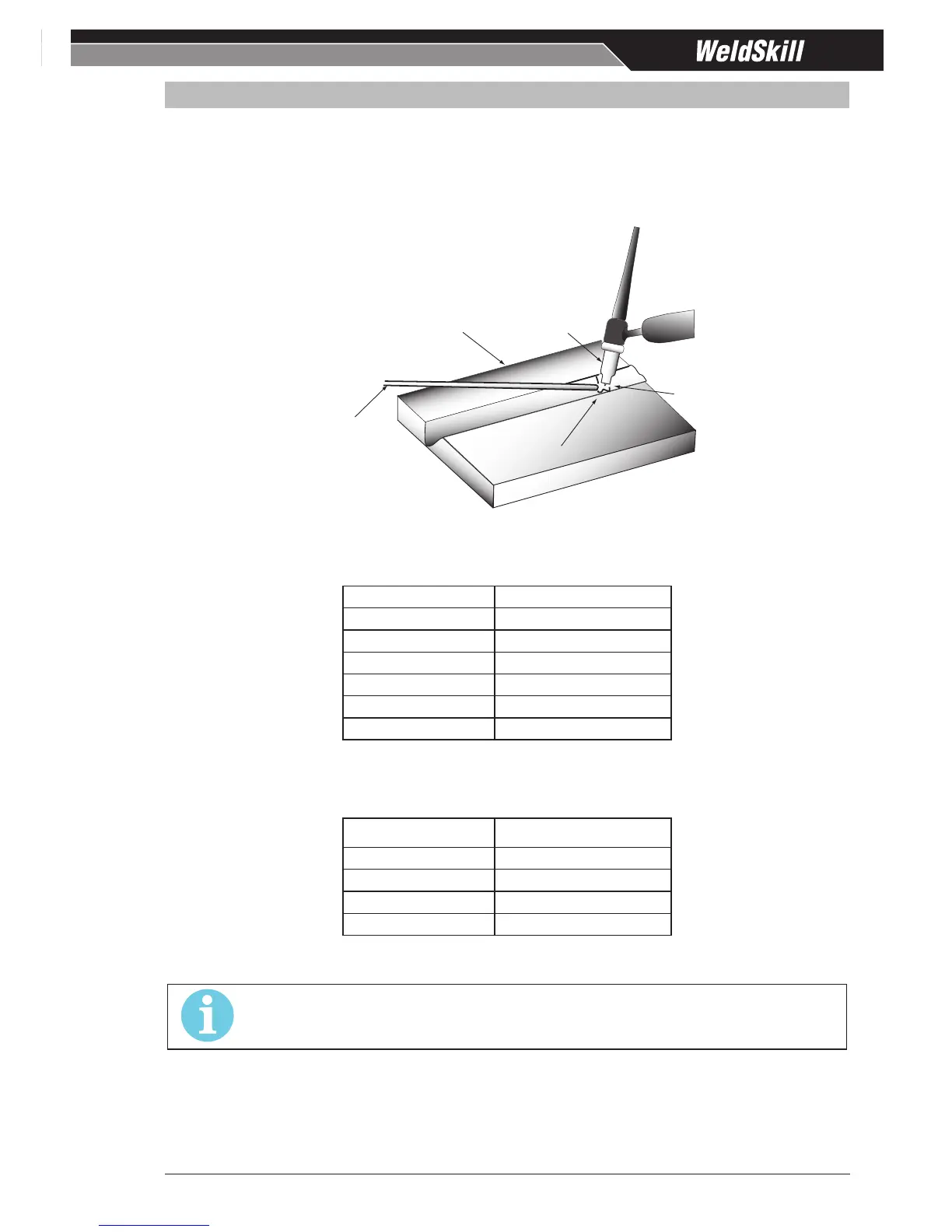

Tungsten Electrode Current Ranges

Electrode Diameter DC Current (Amps)

0.040” (1.0mm) 30-60

1/16” (1.6mm) 60-115

3/32” (2.4mm) 100-165

1/8” (3.2mm) 135-200

5/32” (4.0mm) 190-280

3/16” (4.8mm) 250-340

Table 6-1: Current Ranges for Various Tungsten Electrode Sizes

Guide for Selecting Filler Wire Diameter

Filler Wire Diameter DC Current Range (Amps)

1/16” (1.6mm) 20-90

3/32” (2.4mm) 65-115

1/8” (3.2mm) 100-165

3/16” (4.8mm) 200-350

Table 6-2: Filler Wire Selection Guide

NOTE!

The operator should use the welding current range values as a guide only, then nally adjust the current setting to suit

the application.

Loading...

Loading...