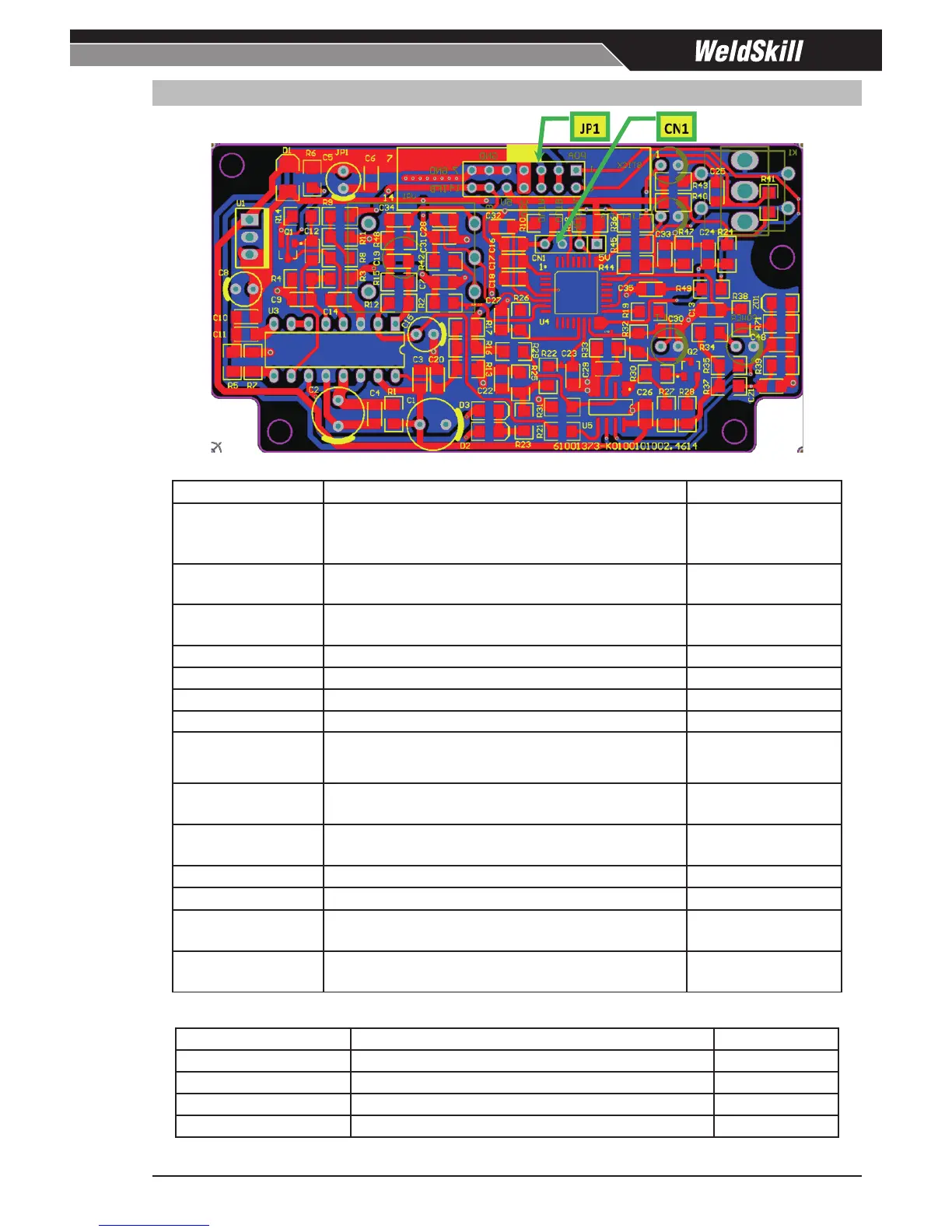

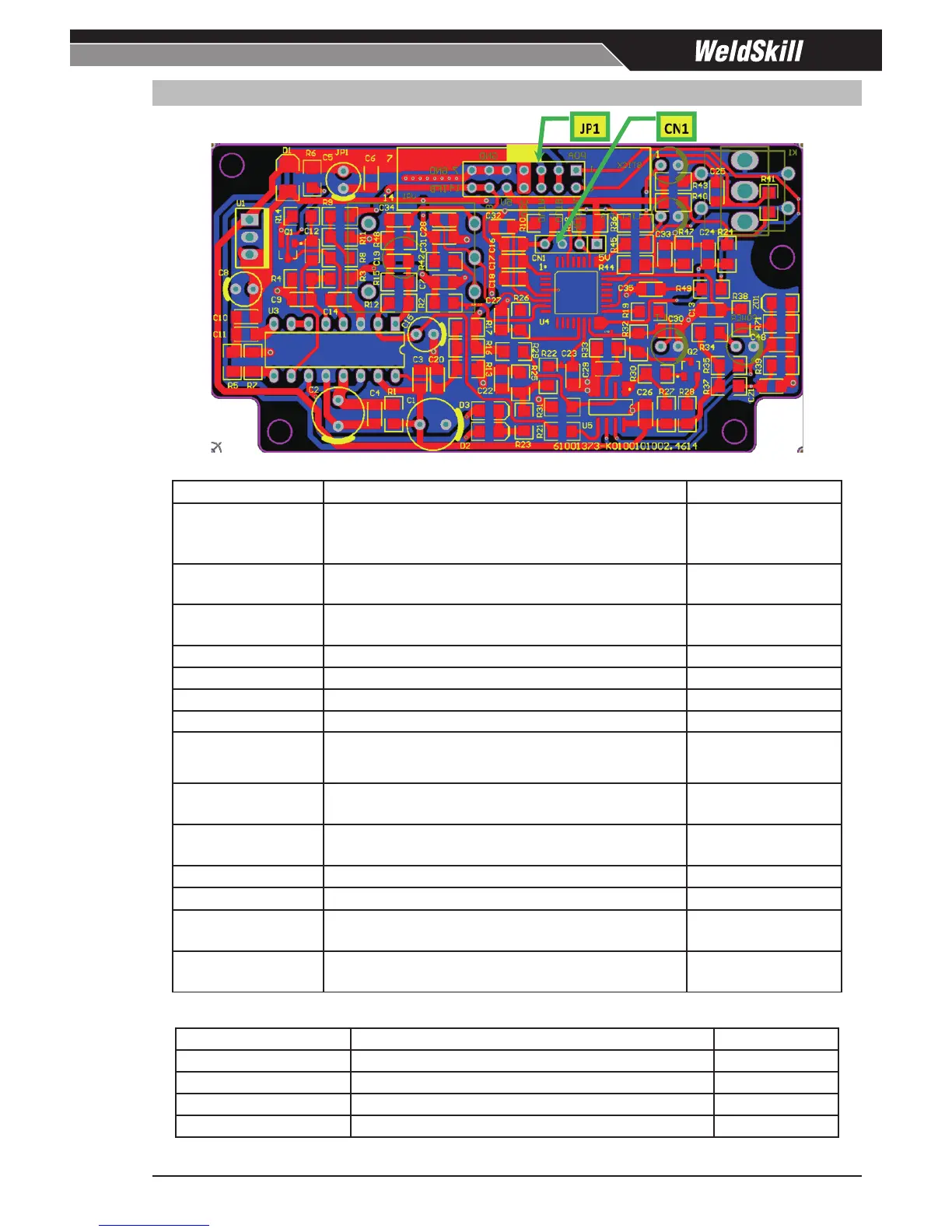

JP1 Header Pin Pin function Signal

1

PDA-SHORT signal which is used to detect a short cir-

cuit at the welding terminals 5V = No short at welding

terminals; 0.2V = Short at welding terminals

5 VDC

2

OUTA IGBT 1/2/3/4 PWM drive signal, 15V p-p square

wave signal

15 VDC pk

3

OUTB IGBT 1/2/3/4 PWM drive signal, 15V p-p square

wave signal

15 VDC pk

4

Vcc-A = +15V supply +15 VDC

5

0V 0 VDC

6

0V 0 VDC

7

0V 0 VDC

8

Thermostat signal from Inverter PCB

2.5 VDC (Tr.1 closed)

5 VDC (Tr.1 open)

9

OUTA IGBT 1/2/3/4 PWM drive signal, 15V p-p square

wave signal

15 VDC pk

10

OUTB IGBT 1/2/3/4 PWM drive signal, 15V p-p square

wave signal

15 VDC pk

11

Vcc-A = +15V supply 15 VDC

12

+5V supply to Inverter PCB +5 VDC

13

PEAK-IFB Primary current feedback signal from

Inverter PCB

14

PEAK-IFB Primary current feedback signal from

Inverter PCB

Table 12-6 JP1 Header pin function (connects to JP1 header on Inverter PCB)

CN1 Header Pin Pin function Signal

1 +5V supply +5 VDC

2

Programming pin

Digital Signal

3

0V 0 VDC

4

Reset pin Digital Signal

Table 12-7 CN1 Header pin function (used for uploading program to Control PCB)

Loading...

Loading...