14

MODELS

DRIVE

SHAFT

BOLT

SIZE

/GRADE

TIGHTEN-

ING

TORQUE

ft-lbs

C32H0-

UFAC10

C32H0-

UFAC18

C32H0-

UFAC20

C32H0-

UFAC28

C32H0-

UFAC30

C32H0-

UFAC38

C32H0-

UFAC40

C32H0-

UFAC48

C32H0-

UFAC50

C32H0-

UFAC58

C32H0-

UFAC60

C32H0-

SC2390A

M16,

Class 10.9

(Metric)

(Hi-

Tensile)

210 - 220

(285 - 298)

(see note #2,

#3)

Note 1 – It is recommended that a medium strength

threadlocker (Loctite 243–blue) be used in the

assembly and of all hardware. This may be purchased

as part number C126758, 50ml bottle.

Note 2 – 4 of the hi-tensile bolts and/or nuts, that are

used to connect the driveshaft to the drive disc and that

connect the driveshaft to the pump companion flange,

will require a “crow’s foot” wrench attached to a

standard torque wrench to apply the required tightening

torque. A standard socket will not work due to

proximity of the bolts and/or nuts with the driveshaft

yoke. The tightening torque values listed for these

bolts and/or nuts have been corrected for using a

“crow’s foot” adapter which extends the standard

torque wrench’s length.

Note 3 – For the high torque required for these nuts, it

is recommended that a boxed-end crows foot be used.

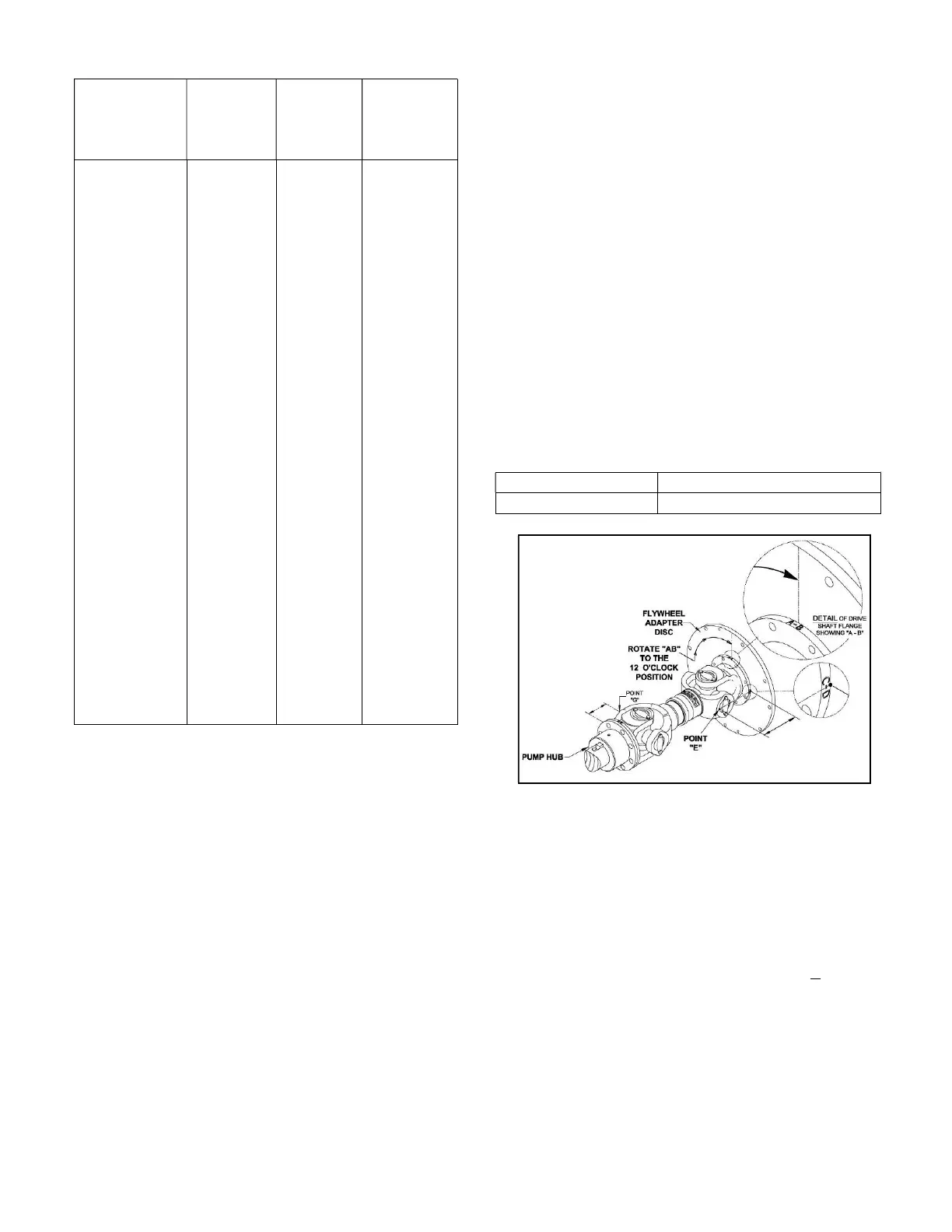

The following steps describe the proper way to check

alignment. A small pocket scale or ruler with

millimeter markings is recommended to make all

measurements.

Before removing the drive shaft guard, disconnect the

negative battery cable from both batteries.

A) To check the Horizontal Parallel Offset, the

driveshaft must be in the proper orientation.

1. Rotate the shaft so the reference “AB” on the

flywheel adapter disc or the circumference of

the drive shaft flange (against the flywheel

adapter disc) is in the 12 o’clock position

shown on Figure #7a.

2. Measure from the face of the flywheel adapter

disc to point E. (Point E is on the bearing bore

as shown in Figure #7a). This measurement

must be:

142.5 + 1.5mm SC2390A

Figure #7a

B) With the driveshaft in the same orientation as the

previous step (Step A), check the Horizontal

Angular alignment of the shafts.

1. Measure from the mating surface of the

companion hub to point G shown on figure

#7b. (Point G is the furthermost point on the

bearing bore). This measurement must be

equal to the measurement at point E + 0.5 mm.

Loading...

Loading...