43

(Note: There is no engine mounted High

Coolant Temperature switch to jumper

across).

Alarm 4: Over crank:

Lift and hold the OVERSPEED RESET

SWITCH for 5 seconds prior to initiating the

6 crank cycles from the fire pump controller.

Ensure that the OVERSPEED RESET

SWITCH is held for the entire duration of

each of the 6 crank attempts. Each time,

while the engine is resting for 15 seconds

between cranking attempts, release the

OVERSPEED RESET SWITCH for 3

seconds. Before the engine cranks again,

activate the OVERSPEED RESET SWITCH

and continue holding throughout the crank

attempt, releasing in between each attempt.

NEVER shut off the fuel supply to the

engine to prevent it from starting. Shutting

off the fuel supply will cause an air lock

condition in the fuel system and possibly

cause fuel system component damage.

Alarm 5: Low Engine Coolant Temperature:

With engine at rest, lift low coolant

temperature switch for 25 seconds.

Alarm 6: ECM Warning: Lift the

OVERSPEED RESET SWITCH for 2

minutes with engine not running to verify

ECM Warning Alarm; note engine will

automatically switch to alternate ECM.

Alarm 7: ECM Failure: After ECM Warning

Alarm has been tested, continue lifting

OVERSPEED RESET SWITCH for

additional 2 minutes with engine not running

to verify ECM Failure Alarm. After

activation of both ECM Warning and Failure

Alarms, activate the ECM Failure Reset

Switch inside the engine control panel.

3.5.5 Battery Requirements

All Clarke engine models require 8D batteries, as

sized per SAE J537 and NFPA20. The battery

should meet the following criteria:

Cold Cranking Amps (CCA @ 0°F): 1200

Reserve Capacity (minutes): 430

Refer to Clarke drawing C131885 (see

www.clarkefire.com) for additional information

on Clarke supplied batteries.

3.6 ENGINE SPEED ADJUSTMENT

All governor and speed control functions are

programmed into each ECM at the factory. During

Start-Up Inspection, some minor speed adjustment

may be required.

To adjust the speed of the engine:

A. Start the engine by following the “To Start

Engine” Procedure in this manual.

B. Let the engine warm-up.

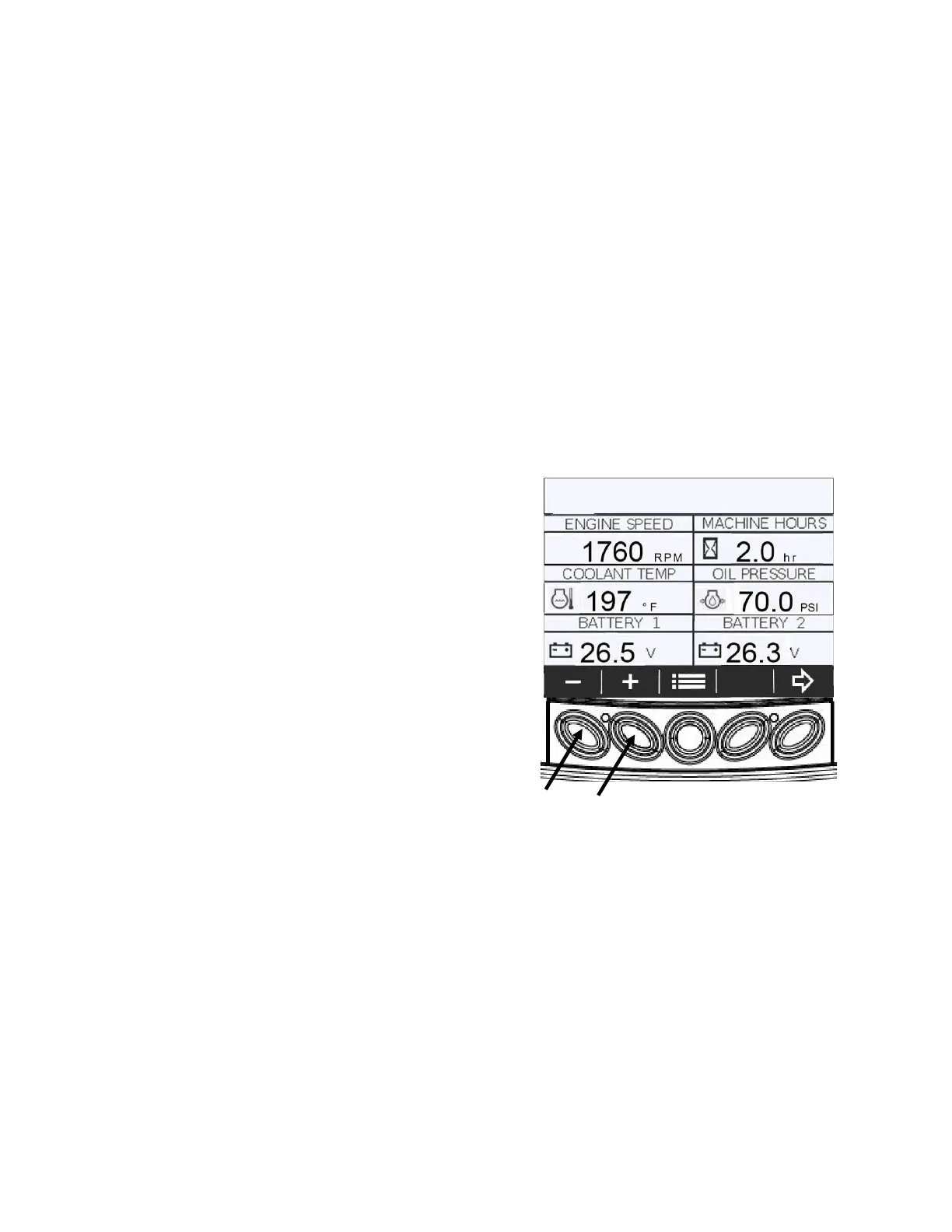

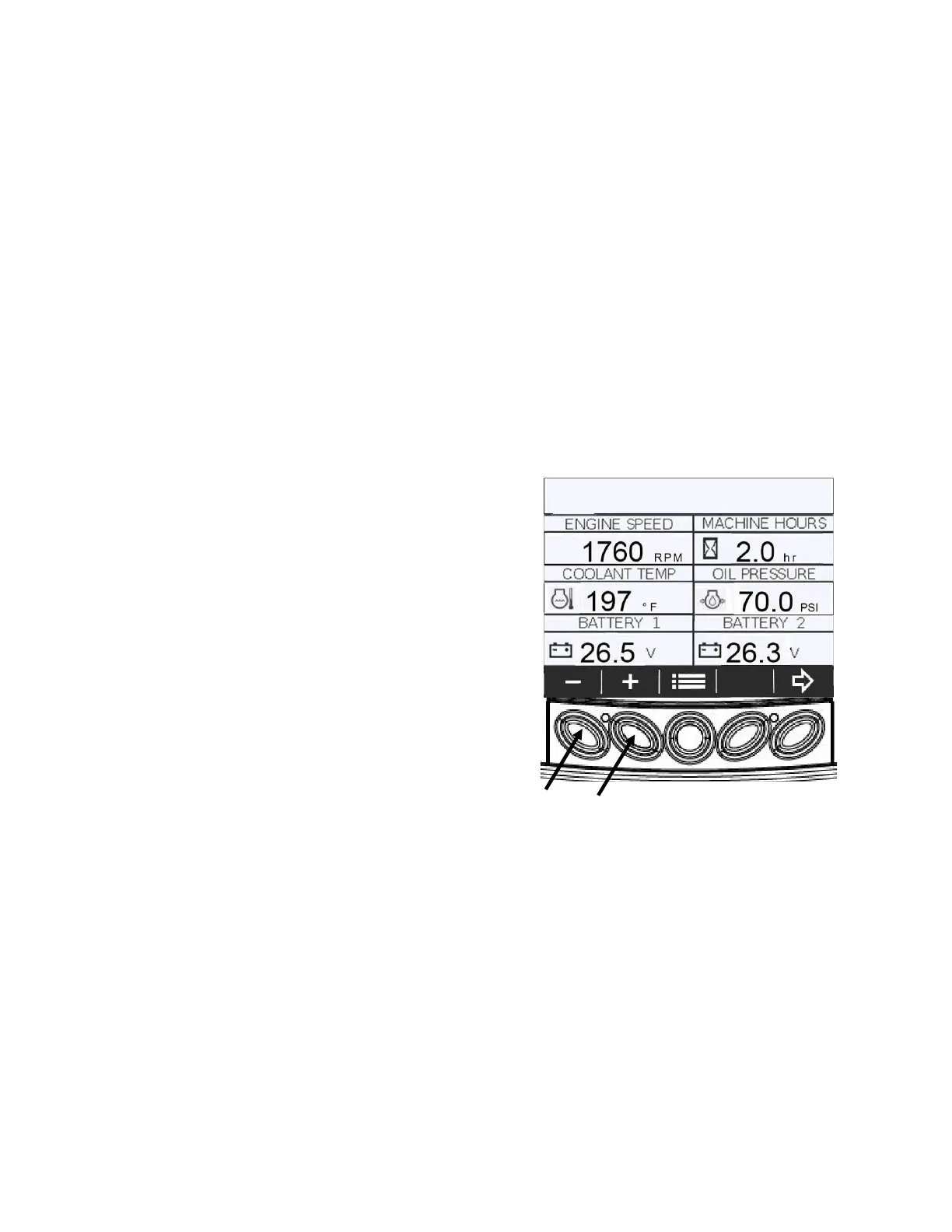

C. While observing the tachometer on the

Powerview Gauge, from the 6-up display,

press the appropriate bump switch on the

gauge. (Refer to Figure # 23).

D. Speed will increment by 5 rpms each time +

or – is pressed.

E. Stop engine by following “To Stop Engine”

Procedure in this manual.

F. Switch to Alternate ECM and repeat steps A

through D.

G. Stop engine by following “To Stop Engine”

Procedure in this manual.

H. Switch back to Primary ECM.

Figure #23

4.0 MAINTENANCE SCHEDULE

4.1 ROUTINE MAINTENANCE

NOTE: The following Routine Maintenance schedule

is based on an engine usage rate not exceeding 2

hours per month. For UL/FM engine models, also

refer to NFPA25.

LEGEND:

Check

Clean

Replace

o Lubricate

Bump

Switches

Loading...

Loading...