36

greatly reduce the cooling systems efficiency and

protection capabilities.

Recommended supplemental coolant inhibitors are a

combination of chemical compounds which provide

corrosion protection, cavitation suppression, pH

controls and prevents scale. These inhibitors are

available in various forms, such as liquid packages or

integral parts of an extended life coolant.

It is imperative that inhibitors are used in all Caterpillar

engine cooling systems. A pre-charge dosage must be

used at the initial fill with a conventional coolant, that

is not fully formulated, and the maintenance dosage

must be added at each service interval. Conventional

coolants must meet ASTM D4985 or ASTM D6210 to

be used in Cat engines. Conventional coolants rely on

inorganic inhibitors and are (re)charged with a

Supplemental Coolant Additive (SCA)

An extended life coolant that meets ASTM D4985 or

ASTM D6210 and contains less than 125 ppm of

silicon (present as silicate) can be used in Cat engines

to the recommended maximum service life. Extended

life coolants rely on organic inhibitors and are

recharged with an Extender. Extenders are typically

added at one half the service life of the coolant.

Inhibitors become depleted through normal

operation; additional inhibitors must be added to

the coolant as required to maintain original

strength levels.

To properly check inhibitor concentration, it may be

necessary to contact your local Service/Dealer for

assistance. Refer to Parts Information Section to

obtain the part number for the factory Coolant Analysis

Kit. This kit can be purchased for a nominal fee for

analyzing the conditions of the engine’s coolant.

3.4.6 Procedure for Filling Engine

During filling of the cooling system, air pockets may

form. The system must be purged of air prior to being

put in service. This is best accomplished by filling

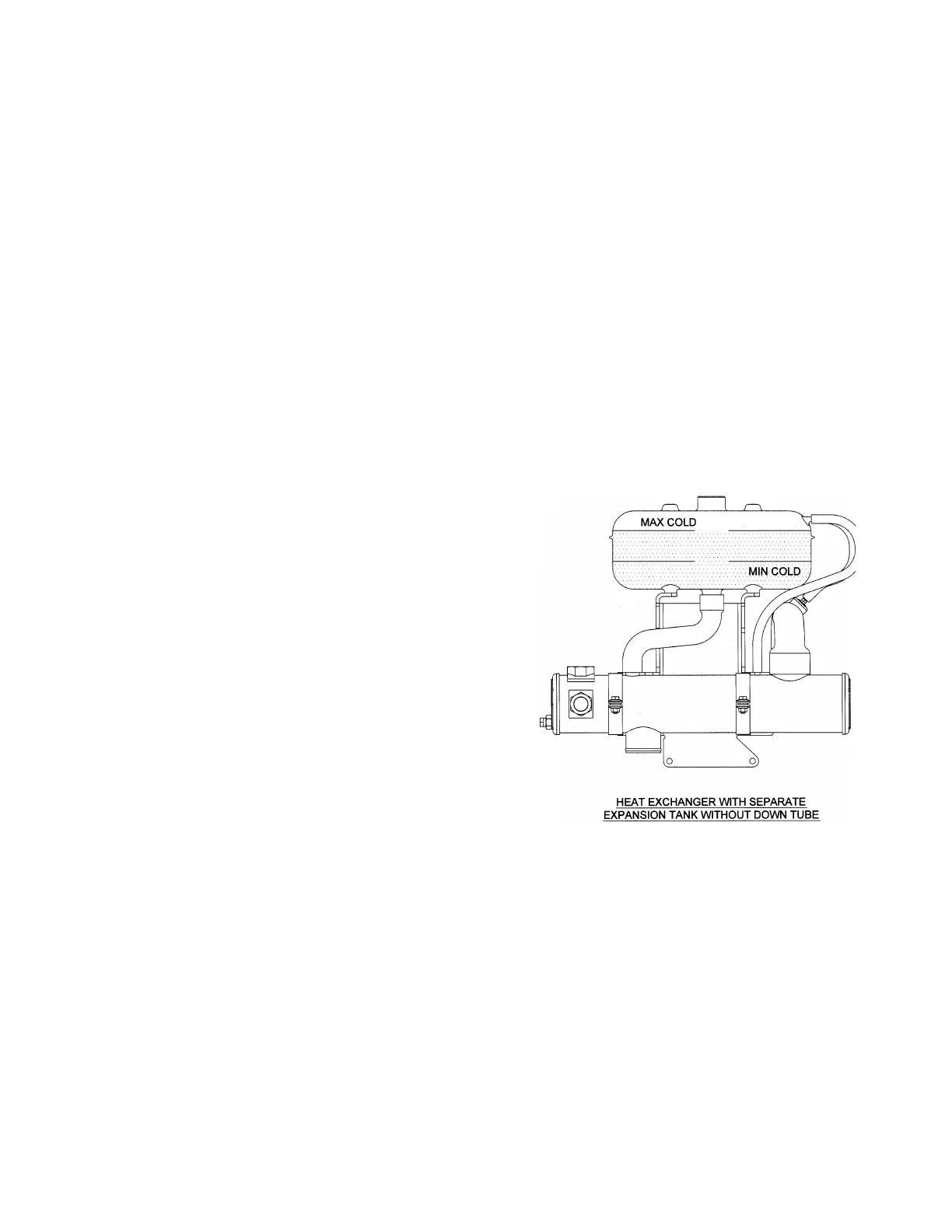

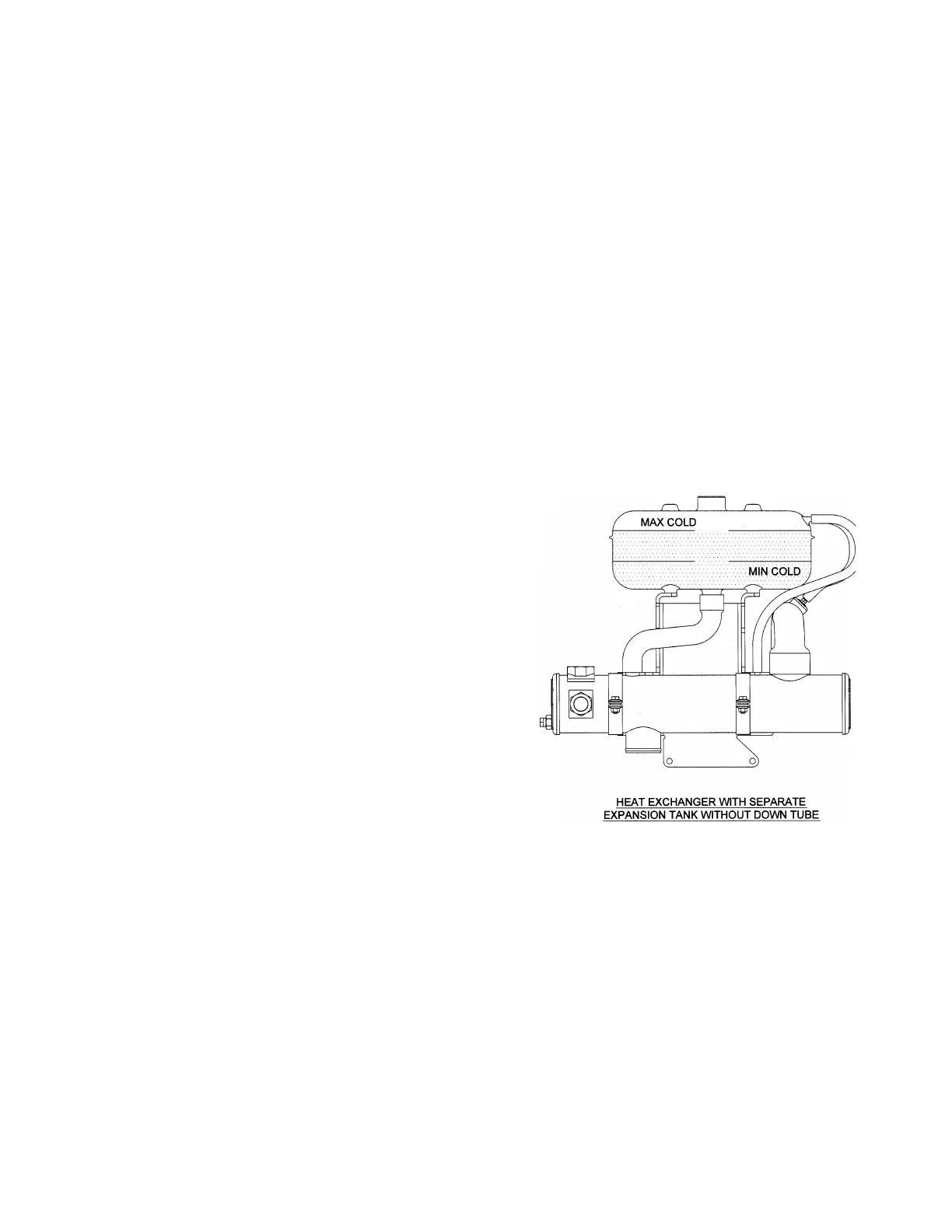

with a pre-mix solution. Refer to Figure #18 for proper

fill level.

Caution: Do not overfill cooling system. A

pressurized system needs space for heat

expansion without overflowing.

Install the pressure cap, start and run engine for

approximately 5 minutes to purge the air from the

engine cavities.

When verifying that the coolant is at a safe operating

level, it is best to wait until the engine temperature

drops to approximately 120ºF (49ºC), or lower, before

removing the pressure cap.

Remove the pressure cap and refill to the proper fill

level. To continue the de-aeration process, start and

run engine until the temperature stabilizes at

approximately 160°-200° (71°-93° C) or run engine for

25 minutes, whichever is longer. During this warming

process, you may see coolant coming from the

overflow tube attached at the pressure cap location.

Allow engine to cool, then remove the pressure cap

and refill to the proper fill level.

Caution: Do not remove pressure cap while coolant is

at normal operating temperatures. Possible personal

injury could result from the expulsion of hot coolant.

Figure #18

3.4.7 Providing Adequate Raw Water Supply to the

Engine Heat Exchanger

3.4.7.1 Raw Water Supply

Most Clarke diesel engine fire pump drivers are heat

exchanger cooled and some engines also have a charge

air cooler (CAC) that uses raw water to cool the air

before entering the intake manifold. If you have a

radiator cooled Clarke engine, you can disregard this

section. Heat exchanger cooled diesel engine drivers

require a clean source of pressurized water from the

discharge side of the fire pump. To prevent

overheating, the loop must provide a specified

minimum amount of raw water flow.

Loading...

Loading...