35

coolant temperature sensor monitors coolant

temperature and will set an alarm at 210º F (103º C).

3.4.2 Engine Coolant

The following information is provided as a guide for

Caterpillar Engine users in the selection of a suitable

coolant.

The water/ethylene glycol/inhibitor coolant mixture

used in Caterpillar engines must meet the following

basic requirements:

Provide for adequate heat transfer.

Provide protection from cavitation damage.

Provide a corrosion/erosion-resistant

environment within the cooling system.

Prevent formation of scale or sludge deposits

in the cooling system.

Be compatible with engine hose and seal

materials.

Provide adequate freeze and boil over

protection.

WARNING

A water and anti-freeze solution is required for

pump installations. Premixing this solution prior to

installing is required. This prevents possible pure

anti-freeze chemical reactions to block heater

elements which can burnout the element. Please see

the I&O section (see Page 5) for proper cooling

system capacities of each model.

3.4.3 Water

Water can produce a corrosive environment in the

cooling system, and the mineral content may permit

scale deposits to form on internal cooling surfaces.

Therefore, inhibitors must be added to control

corrosion, cavitation, and scale deposits.

Chlorides, sulfates, magnesium and calcium are among

the materials which make up dissolved solids that may

cause scale deposits, sludge deposits, corrosion or a

combination of these. Chlorides and/or sulfates tend to

accelerate corrosion, while hardness (percentage of

magnesium and calcium salts broadly classified as

carbonates) causes deposits of scale. Water within the

limits specified in the following table is satisfactory as

an engine coolant when properly inhibited. Use of

distilled water is preferred.

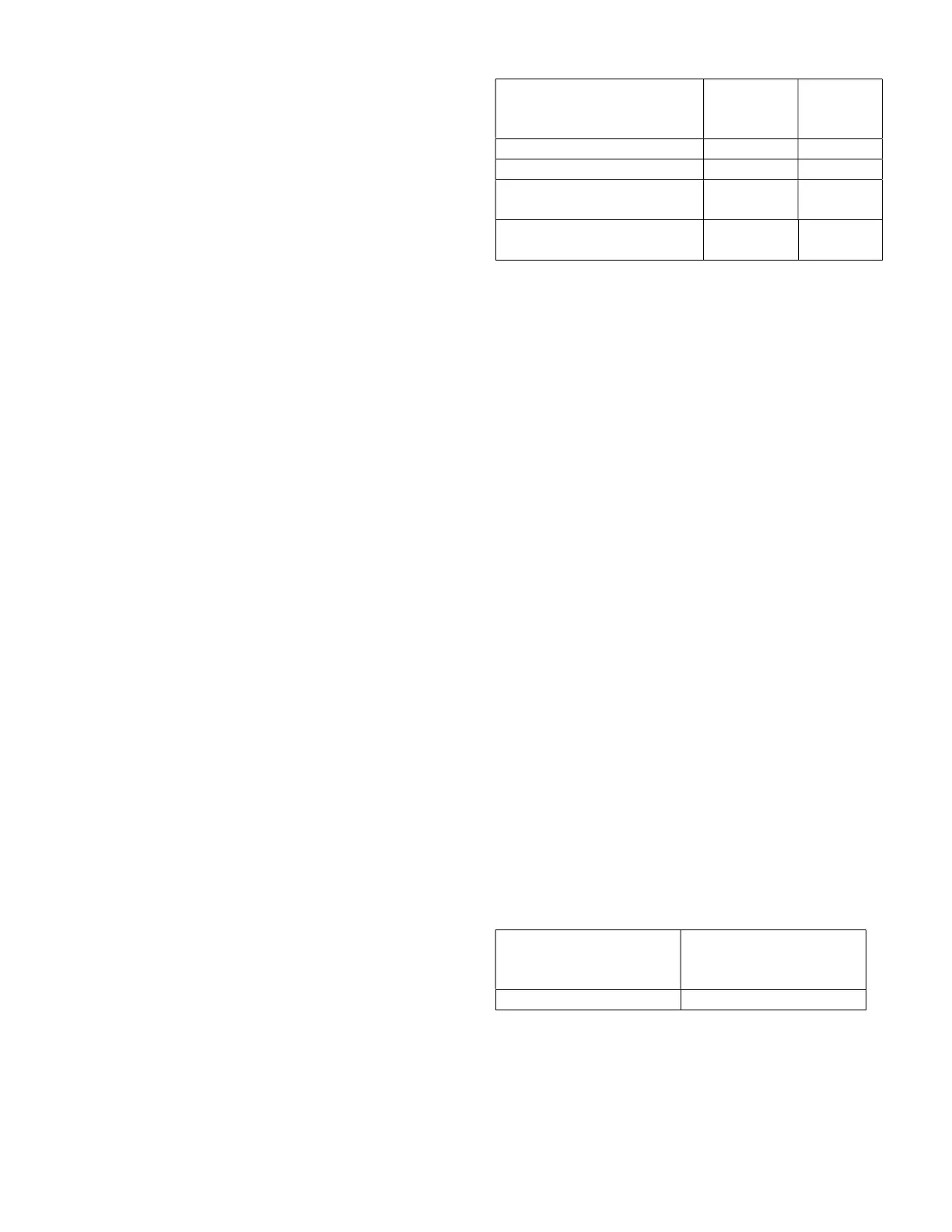

Materials

Milligram

per Liter

Grains

per

Gallon

Total Dissolves Solids

Total Hardness (Max.)

3.4.4 Coolant Capacities

Ethylene Glycol or Propylene Glycol are acceptable:

IMPORTANT:

Do not use cooling system sealing additives or

antifreeze that contains sealing additives.

Do not mix ethylene glycol and propylene glycol base

coolants.

Use an ethylene glycol coolant (low silicate

formulation) that meets the standard of ASTM E1177

or propylene glycol that meets ASTM D6210

requirements. Use of propylene glycol requires

addition of CAT SCA (Supplemental Coolant

Additive) to prevent liner cavitation.

A 50% coolant water solution is recommended. A

concentration over 70% is not recommended because

of poor heat transfer capability, adverse freeze

protection and possible silicate dropout.

Concentrations below 30% offer little freeze, boil over

or corrosion protection.

IMPORTANT

Never use automotive-type coolants (such as those

meeting only ASTM D3306 or ASTM D4656).

These coolants do not contain the correct additives

to protect heavy-duty diesel engines. They often

contain a high concentration of silicates and may

damage the engine or cooling system.

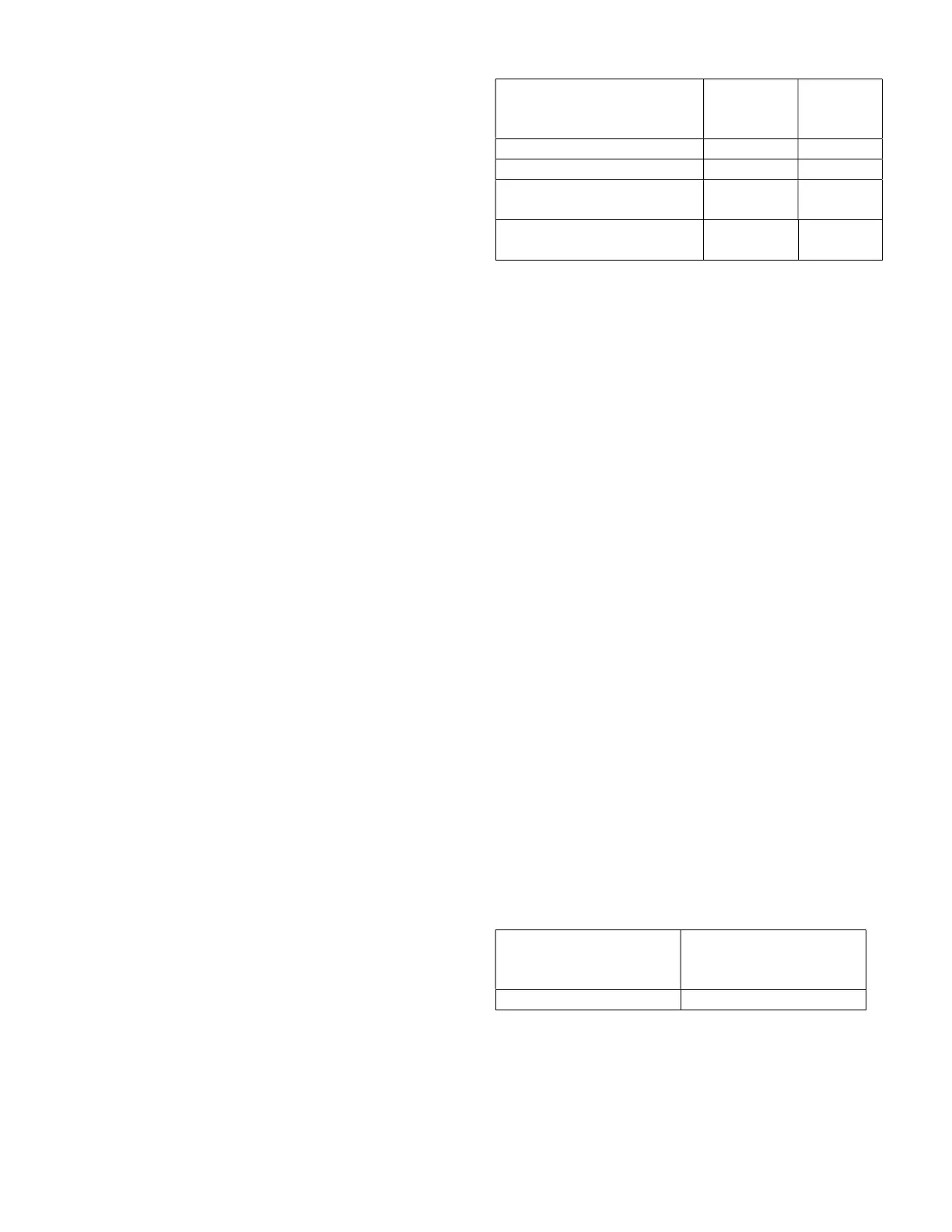

ENGINE

MODEL

COOLANT

CAPACITY

QUARTS (LITERS)

C32H-All Models 83 (78.5)

3.4.5 Coolant Inhibitors

The importance of a properly inhibited coolant cannot

be over-emphasized. A coolant which has insufficient

or no inhibitors at all, invites the formation of rust,

scale, sludge and mineral deposits. These deposits can

Loading...

Loading...