18

necessary to “crank” the engine for the Alternate ECM

to pick-up the same fault code(s).

2.6.3.2 Dual ECM Automatic Switching

Engine models utilizing dual ECMs are equipped with

a BASE unit (Board for Auto-Switching ECMs) that

can detect failure on either primary or alternate ECM.

The BASE monitors two separate heartbeat signals

from each of the ECMs. If the BASE fails to detect

BOTH of these signals, the BASE will recognize this

as an ECM failure and initiate the automatic ECM

switching process. If the BASE fails to detect only one

of these signals, the automatic ECM switching process

will not initiate however an indication will be made by

a green status LED on the BASE.

Normal Operation: LED Flashes at 1/10 Hz or

1 time in 10 seconds

Primary heartbeat failure only: Led Flashes at

½ Hz or 5 times in 10 seconds.

Secondary heartbeat failure only: LED Flashes

at 1 ½ Hz or 15 times in 10 seconds.

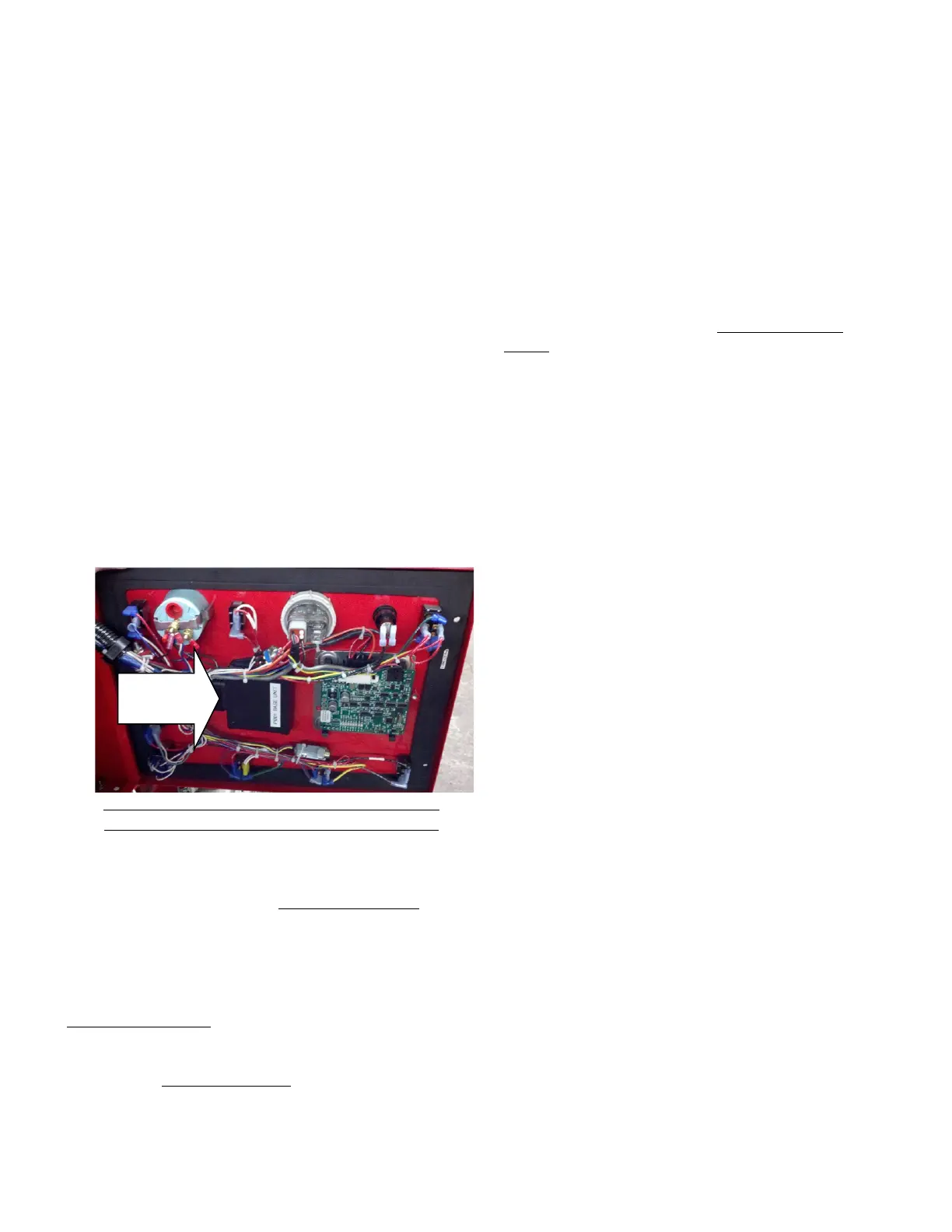

Interior view of engine gauge panel door - BASE

dual ECM auto-switching device and green LED

Figure #9A

If the currently selected ECM experiences a failure

detected by the BASE unit, an ECM warning alarm

will be sent to the fire pump controller via interconnect

terminal 303, and will automatically switch to the other

functional ECM. If the automatic switching devices

switches to alternate ECM, a visual indication light

will illuminate on the engine control panel, and an

alternate ECM alarm will be sent to the fire pump

controller via interconnect terminal 301. Upon failure

of the second ECM, the automatic switching device

will alarm an ECM failure alarm to the fire pump

controller via interconnect terminal 304. Additionally,

the BASE status LED will flash at rate of 2 ½ Hz or 25

times in 10 seconds.

If an ECM failure occurs during engine operation, the

automatic switching device will control engine

shutdown and will prevent starter motor re-engagement

while the engine is shutting down. After the engine

safely comes to a stop the automatic switching device

will switch to the other functional ECM and will then

allow starter motor re-engagement control from the fire

pump controller.

The automatic ECM switching process will not initiate

upon failure of any primary, alternate, or non-critical

engine sensors as per UL/FM.

After ECM repair, activate the ECM Failure reset

switch to the down position for 3 seconds and release.

This will de-activate the ECM Warning and Failure

alarms to the fire pump controller at interconnect

terminals 303 and 304.

The hand operated ECM selector switch allows for

manual selection of either primary or alternate ECM.

In the event of failure of the BASE unit while the

ECMs are functional, a Diagnostic Trouble Code of

SPN 2145 FMI 9 will be displayed on the diagnostic

gauge.

2.6.3.3 Programming ECM with Automatic Switching

Device

This procedure will be performed by Clarke Certified

Service Dealer or a Cat Dealer.

In the event of a failed or damaged ECM,

programming will be required on the replacement unit.

The diagnostic tool will be connected to the Service

Tool Connector (#10 in Figure #8). In addition to the

typical programming procedure used on Caterpillar

engines, some extra steps are required.

To program the Primary ECM:

1) In manual operation mode, select the Primary

ECM with the ECM SELECTOR (#4 on

Figure #8).

2) Unplug the BASE dual ECM auto-switching

device on the back side of the engine gauge

panel door. (See Figure #9B.)

BASE &

green status

LED

Loading...

Loading...