750-91 (revised 2009)

Model CB-LE Packaged Boiler Manual

6-23

6.21 — Fuel Oil Combustion Adjustment

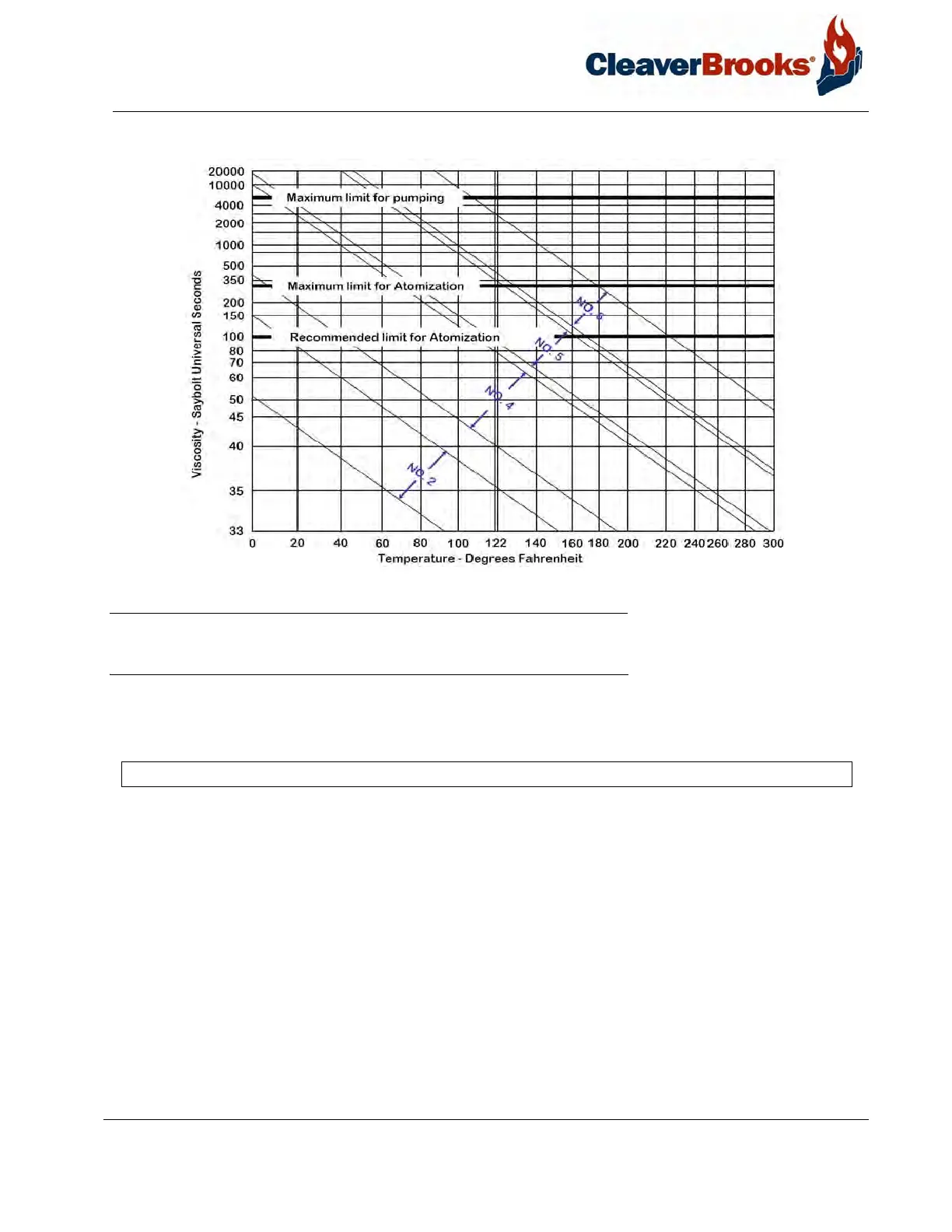

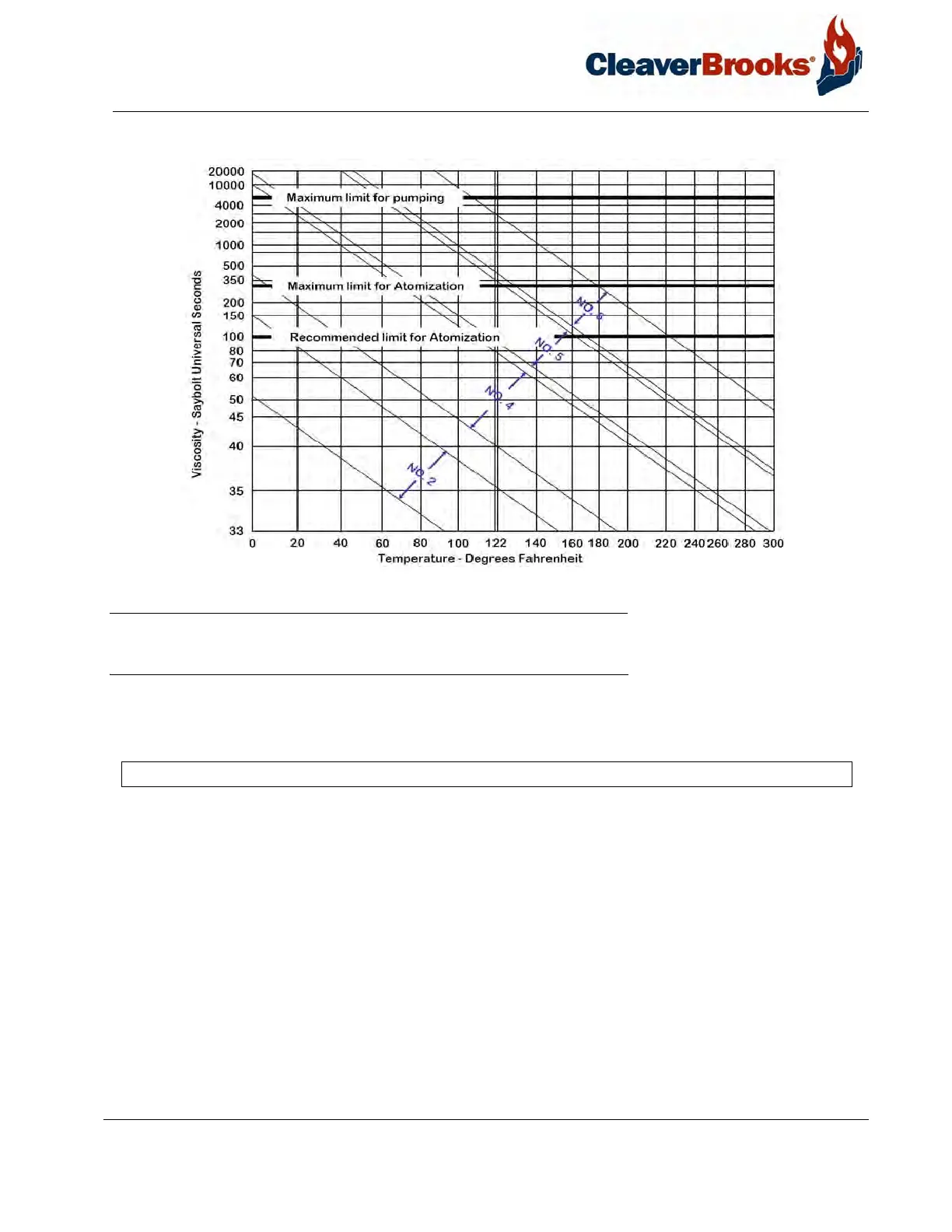

FIGURE 6-15. Oil Viscosity Chart

6.21 — Fuel Oil Combustion Adjustment

After operating for a sufficient period of time to assure a warm boiler, adjustments should be made to obtain effi-

cient combustion.

Burner efficiency is measured by the amount or percentage of O

2

present in the flue gas. O

2

readings determine the

total amount or excess air in the combustion process, above the point of stoichiometric combustion or perfect

combustion. Stoichiometric combustion, however, is the reference point used when setting air/fuel ratios in a

boiler.

There must always be excess air in the combustion process to account for changes in boiler room conditions and to

ensure the combustion is on the proper side of the combustion curve.

Proper setting of the air/fuel ratios at all rates of firing must be established by the use of a combustion gas analyzer.

Efficient combustion cannot be solely judged by flame condition or color, although they may be used in making

approximate settings. Combustion settings should be done so that there is a bright sharp flame with no visible haze.

Most flue gas analyzers in use today measure the content, by percentage, of oxygen (O

2

) and in some cases, smoke.

Carbon dioxide (CO

2

) is not normally measured with modern gas analyzers, but may be displayed as a calculation.

NOTE: All adjustment should be done by a qualified boiler operator or your local Cleaver-Brooks representative.

Loading...

Loading...