Starting and Operating Instructions

5-6

750-91 (revised 2009)

Model CB-LE Packaged Boiler Manual

6. Observe the regulated oil pressure gauge for indication that flow is established. If no pressure shows on the

gauge after a few moments, stop the oil pump and re-prime.

If the supply tank is lower than the pump, it is possible that the initial priming of the suction line, followed by

operation of the pump, will not establish oil flow. This might be caused by obstruction in the suction line, exces-

sive lift, inadequate priming, suction line leaks, etc.

If oil flow is not readily established, avoid prolonged operation of the pump to minimize risk of damage to

internal parts of the pump.

7. A vacuum (or a compound pressure-vacuum) gauge should be installed at the suction port of the pump and its

reading observed and recorded for future guidance. If a vacuum condition exists, the reading will reveal the

tightness of the system. It is advisable to maintain the vacuum reading at less than 10” Hg.. A vacuum in excess

of 10” Hg. may allow oil to vaporize, causing cavitation, loss of prime, and unstable firing condition.

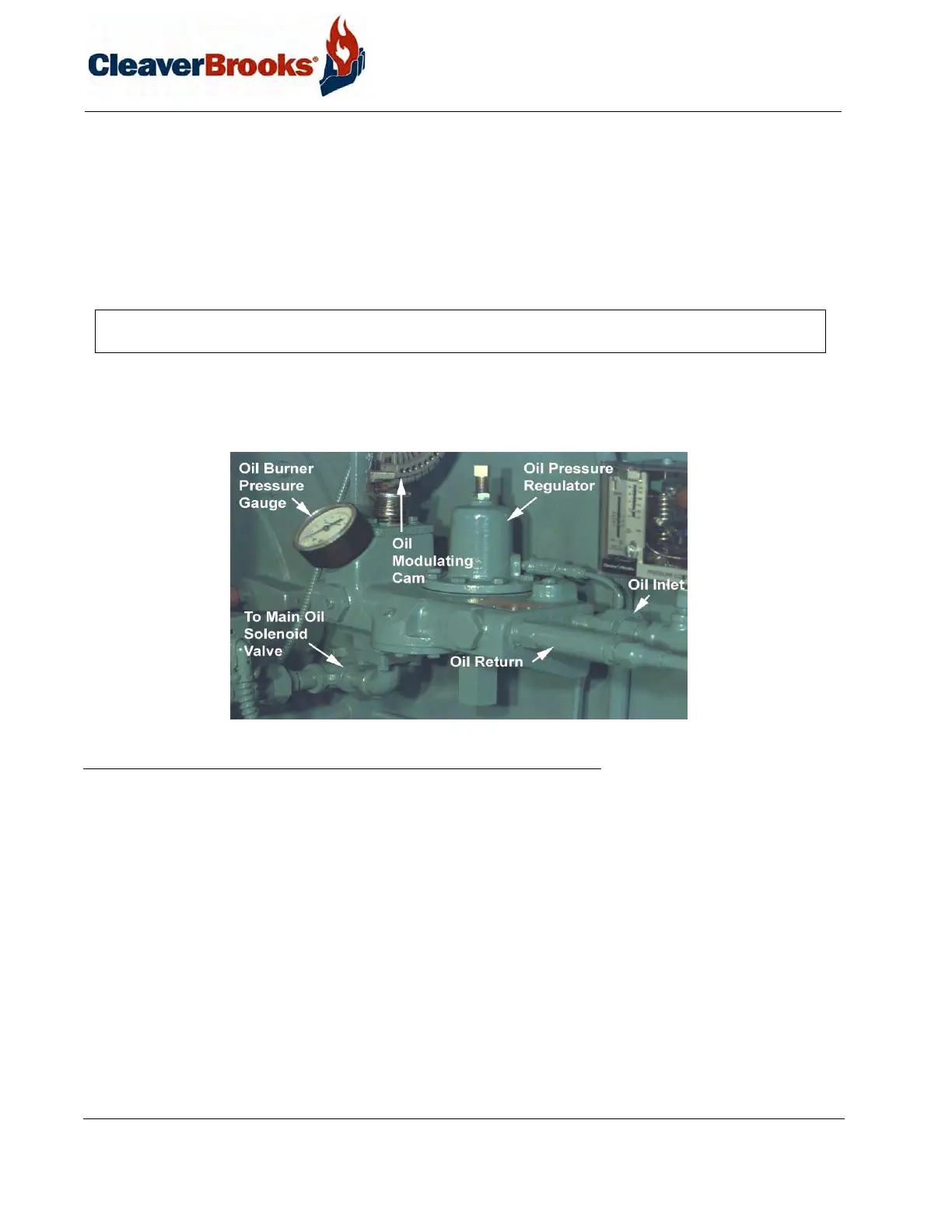

FIGURE 5-3. No.2 Fuel Oil Control

5.5.2 — Oil Pressure

1. Oil supply pressure is regulated by adjusting the pressure relief valve at the oil terminal block. A pressure gauge

should be installed in the terminal block and the relief valve adjusted to obtain a minimum reading of 75 psi

when the burner is firing at maximum rate.

2. When oil is supplied from a pressurized loop to a multiple boiler installation, the relief valve in the loop should

be properly adjusted to provide this reading. In this circumstance, the relief valve at the terminal block should

be adjusted to the point when it will be inoperative (or removed and openings plugged). To render inoperative,

turn the adjusting screw in as far as possible.

3. Adjustment may also be required to the regulator on the fuel oil controller. The pressure regulating valve is

equipped with tubing that directs and adds atomizing air pressure to the adjustable spring pressure. Since the air

pump is not running at this time, only tentative adjustment can be made. Without the air supply, adjust the fuel

oil pressure regulator so that the oil burner gauge registers approximately 35 psi.

NOTE: If oil flow is not established after a second or third priming attempt, a full investigation is required to deter-

mine the cause.

Loading...

Loading...