750-91 (revised 2009)

Model CB-LE Packaged Boiler Manual

1-7

1.4 — Steam Controls (All Fuels)

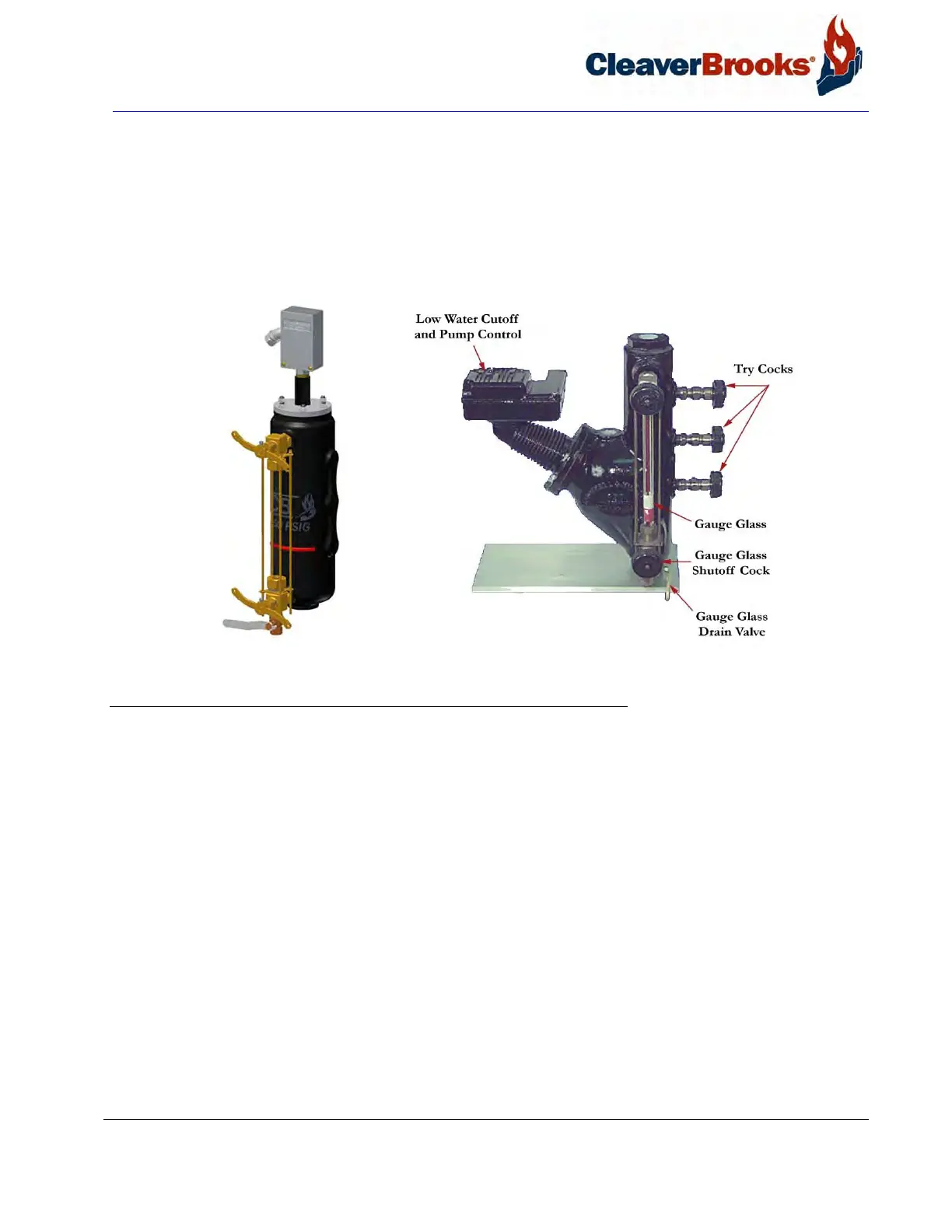

1.4.6 — Water Column Drain Valve

Provided so that the water column and its piping can be flushed regularly to assist in maintaining cross-connecting

piping and in keeping the float bowl clean and free of sediment. A similar drain valve is furnished with auxiliary

low-water cutoff for the same purpose.

1.4.7 — Water Gauge Glass Drain Valve

Provided to flush the gauge glass.

FIGURE 1-4. Water Column Assembly & LWCO

1.4.8 — Vent Valve

Allows the boiler to be vented during filling, and facilitates routine boiler inspection as required by ASME Code.

1.4.9 — Stack Temperature gauge

Indicates flue gas outlet temperature.

1.4.10 — Auxiliary Low-Water Cutoff

Breaks the circuit to stop burner operation in the event boiler water drops below the master low-water cutoff point.

Manual reset type requires manual resetting in order to start the burner after a low-water condition.

1.4.11 — Safety Valve(s)

Prevents buildup over the design pressure of the pressure vessel. The size, rating, and number of valves on a boiler

is determined by the ASME Boiler Code. The safety valve and the discharge piping are to be installed to conform

to the ASME Code requirements. The installation of a valve is of primary importance to its service life. A valve

must be mounted in a vertical position so that discharge piping and code required drains can be properly piped to

CB LEVEL MASTER

(HIGH PRESSURE STEAM)

LOW PRESSURE STEAM

Loading...

Loading...