750-91 (revised 2009)

Model CB-LE Packaged Boiler Manual

8-15

8.14 — Inspection and Adjustment

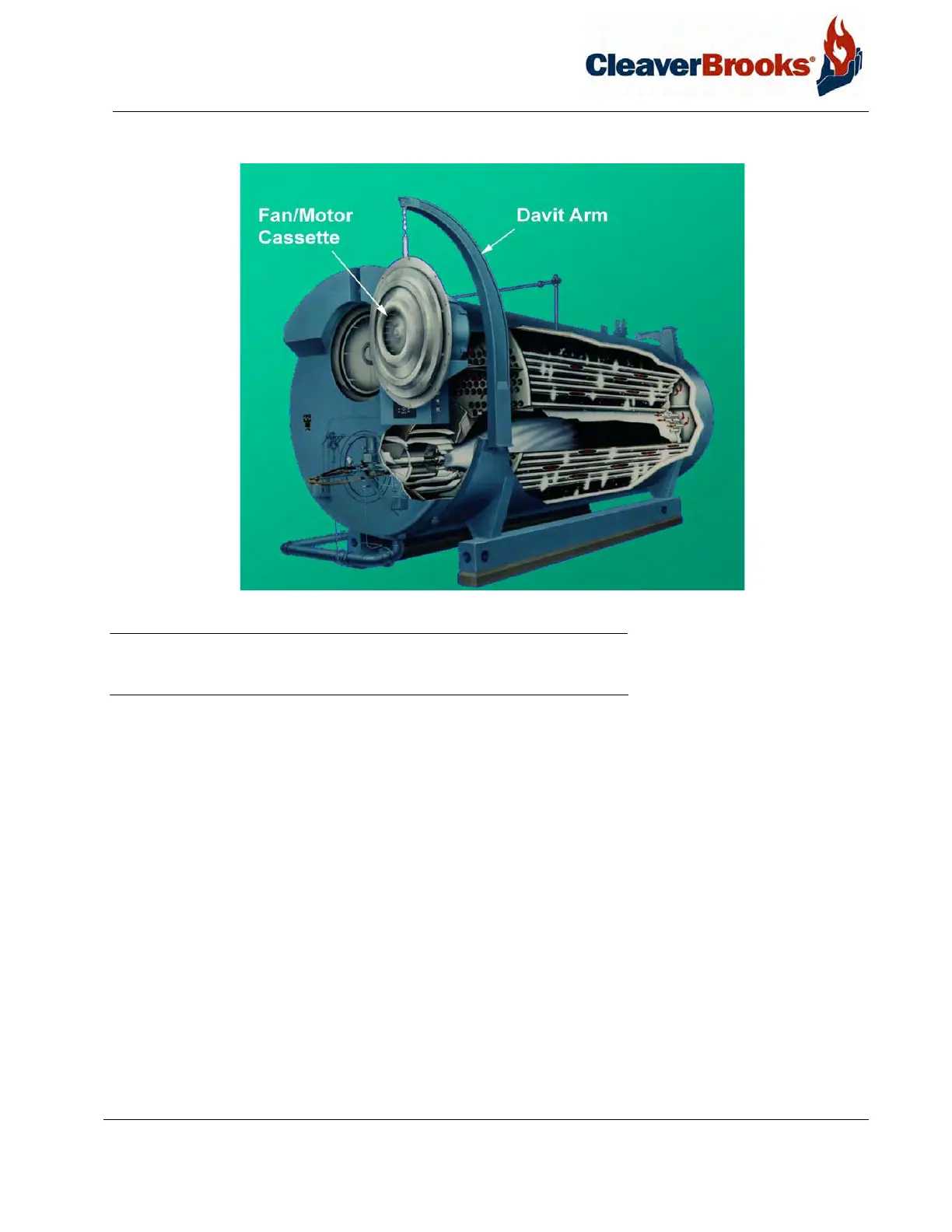

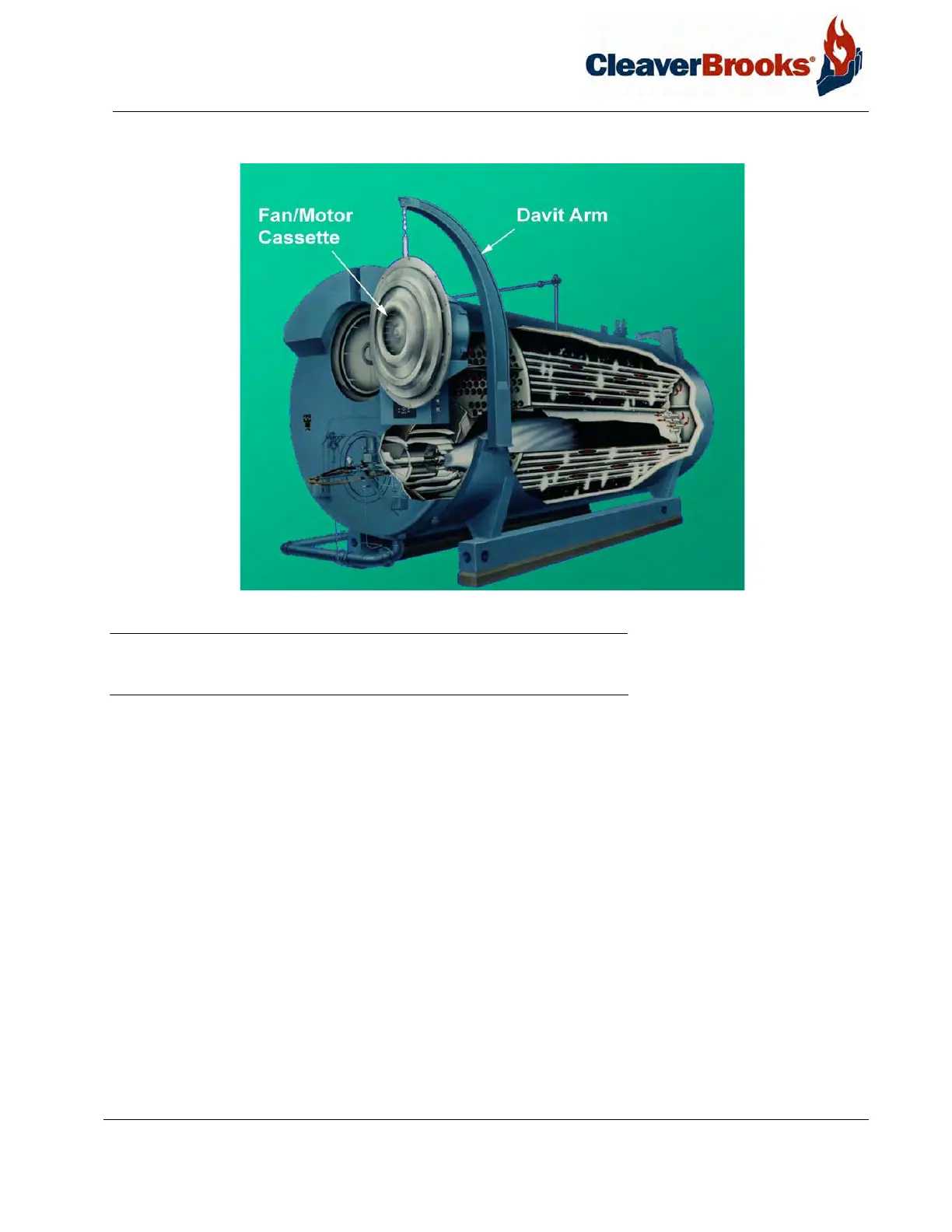

FIGURE 8-4. Fan/Motor Cassette Removal

8.14 — Inspection and Adjustment

NOx levels should be checked periodically to ensure compliance with all local and federal regulations, as well as to

ensure that the boiler is operating at maximum efficiency. Linkages should be inspected and free movement (no

binding) of the IFGR damper confirmed.

Increasing or decreasing NOx levels could indicate incorrect damper positioning, loose linkages, an improper air-

to-fuel ratio, or stack draft changes. If adjustment is required, or if problems persist, contact your local Cleaver-

Brooks authorized representative for further assistance.

As ash and products of combustion pass through the IFGR damper, there will be some accumulation on the

damper, windbox, and other parts of the IFGR system and burner.

To ensure proper operation of the IFGR system and burner, inspection and cleaning should be performed at regu-

lar intervals, depending on the load, type of fuel, and combustion temperatures.

1. With the IFGR damper exposed, inspect the internal linkages for secure connections, and check for free move-

ment of the linkage arms and the IFGR damper assembly. Check for free movement of the linkage by separating

the external linkage from the jackshaft drive arm(s) and cycling the exterior linkage through its range of move-

ment.

Loading...

Loading...