Inspection and Maintenance

8-22

750-91 (revised 2009)

Model CB-LE Packaged Boiler Manual

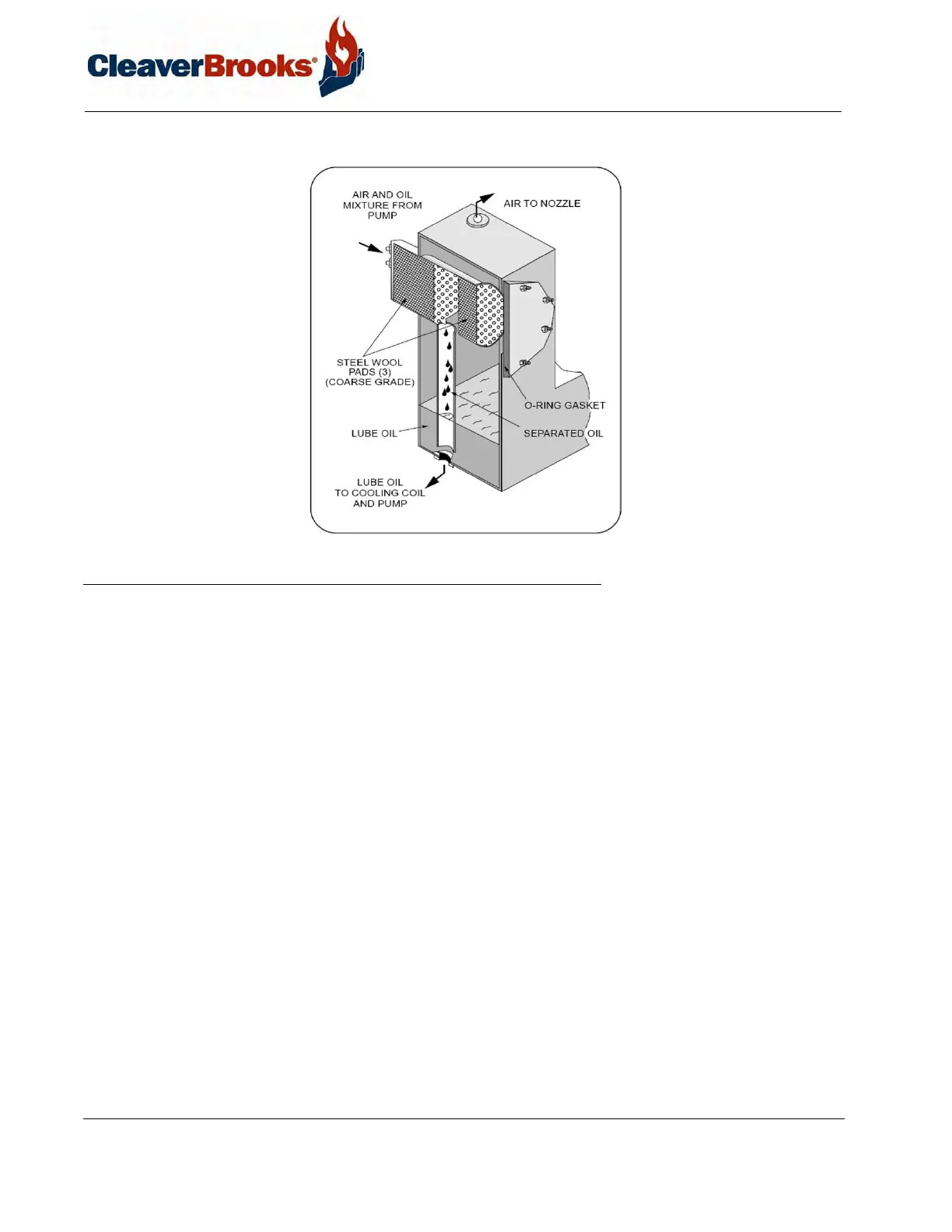

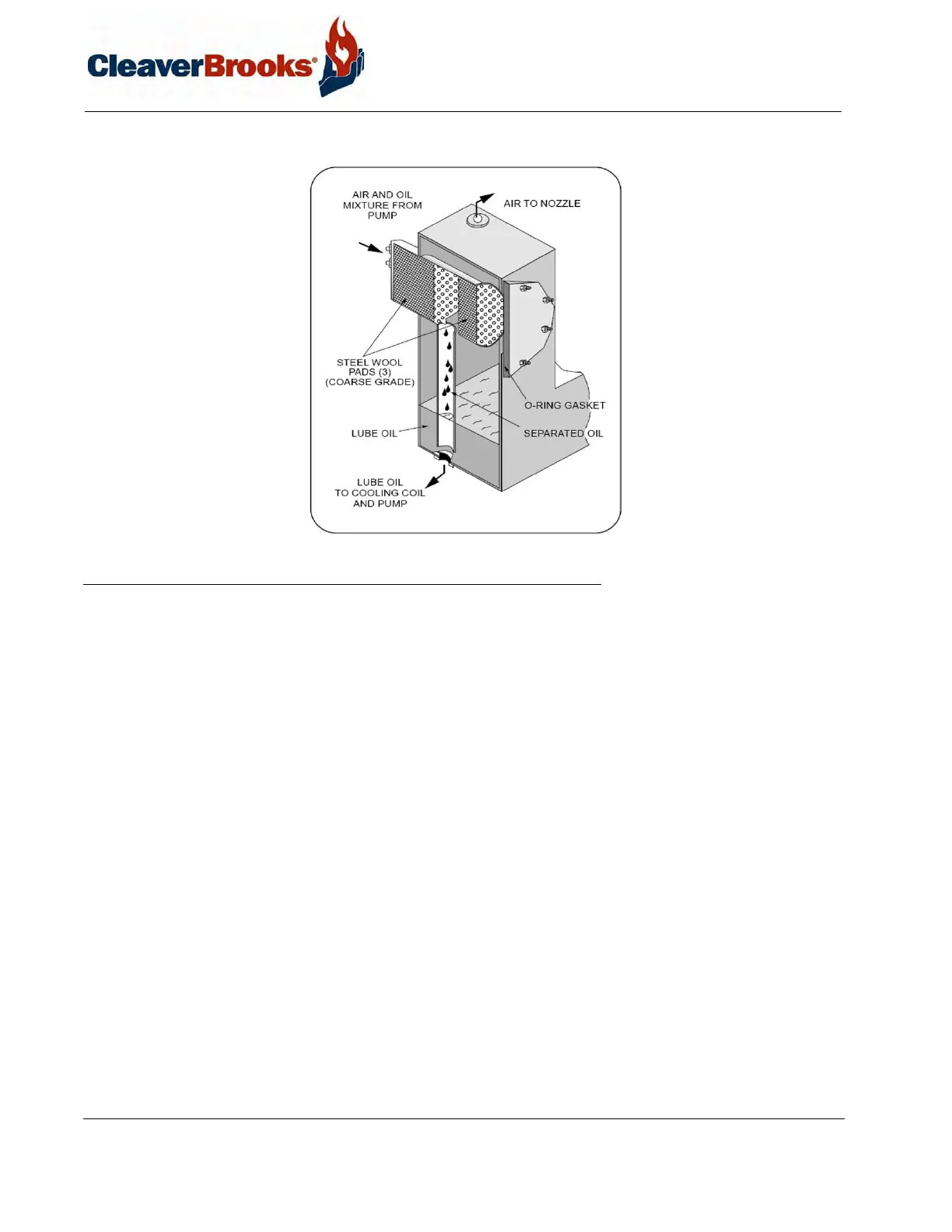

5. Be sure to fit an O-ring gasket under the cover so that a tight seal is obtained.

FIGURE 8-8. Air Oil Receiver Tank

8.19.6 — Lube Oil Cooling Coil

The fins on the tubing must be kept clean and free of any dust or dirt that would resist air flow and cause overheat-

ing. Use an air hose to blow away debris. Internal cleaning of the tubes is seldom required if a good quality lube oil

is used.

8.19.7 — Flexible Coupling Alignment

Alignment of the pump and motor through the flexible coupling is extremely important for trouble free operation.

Check the coupling alignment semi-annually and replace the coupling insert as required. Keep the coupling guard

in place.

The most commonly used tools for checking alignment are a small straightedge and a thickness gauge.

The coupling must be checked for both parallel (offset) alignment and angular (gap) alignment. Parallel misalign-

ment exists when shaft axes are parallel but not concentric. Angular misalignment is the reverse situation — shaft

axes concentric, but not parallel.

Checking parallel alignment, both horizontal and vertical can be accomplished, by laying a straightedge across the

coupling halves and checking with a thickness gauge to obtain the amount of misalignment. The check should be

done on the top of the coupling and at 90 degrees. A useful practice is to hold a flashlight behind the straightedge

so that any gap can readily be seen.

Loading...

Loading...