15

climatemaster.com

Tranquility

®

30 Digital (TE) Series IOM - 60Hz HFC-410A

Rev.: 3 Aug., 2012B

Multiple Unit Piping and Flushing

Often projects require more than one heat pump. Where

possible, it makes sense for multiple units to share a common

ground loop. Common ground loops for multiple units bring

new challenges including the need to avoid backward fl ow

through inactive units, increased pumping requirements,

and more complex fl ushing needs. Three types of multiple

unit systems are described below along with guidelines for

installation of each type.

vFlow™ internal variable fl ow technology is a great assist

for systems with multiple units. vFlow™is available in three

different confi gurations:

1. Internal variable-speed pump

2. I

nternal modulating valve for closed loops

3. Internal modulating valve for open loops

The internal modulating valve for open loops version should

never be used on closed loops.

The internal variable speed pump version of vFlow™includes

an internal Magna variable speed circulator controlled by

the DXM2 microprocessor, internal 3-way fl ushing valves,

an internal bladder type expansion tank, and front-mounted

pressure ports that allow access to the pressure drop across

the coaxial heat exchanger only. The Magna pump includes

an internal check valve. The pump curve for the Magna

circulator is shown in Figure 13. The internal expansion tank

will operate as a pressure battery for the geothermal system.

It will absorb fl uid from the loop when loop pressure rises

and inject fl uid into the loop when loop pressure falls. In this

way the expansion tank will help to maintain a more constant

loop pressure and avoid fl at loops due to seasonal pressure

changes in the loop.

When using the internal variable speed pump as the loop

pump in multiple unit installations it is important to ensure

that the variable speed pump can provide adequate fl ow

through the heat pump against the loop head when all units

are operating.

It may be possible to fl ush a multiple unit system through

the unit’s fl ushing valves. Flushing pressure drop of the

valve may be calculated to determine if it is acceptable.

Engineering data for the 3-way fl ushing valves can be found

in Table X.

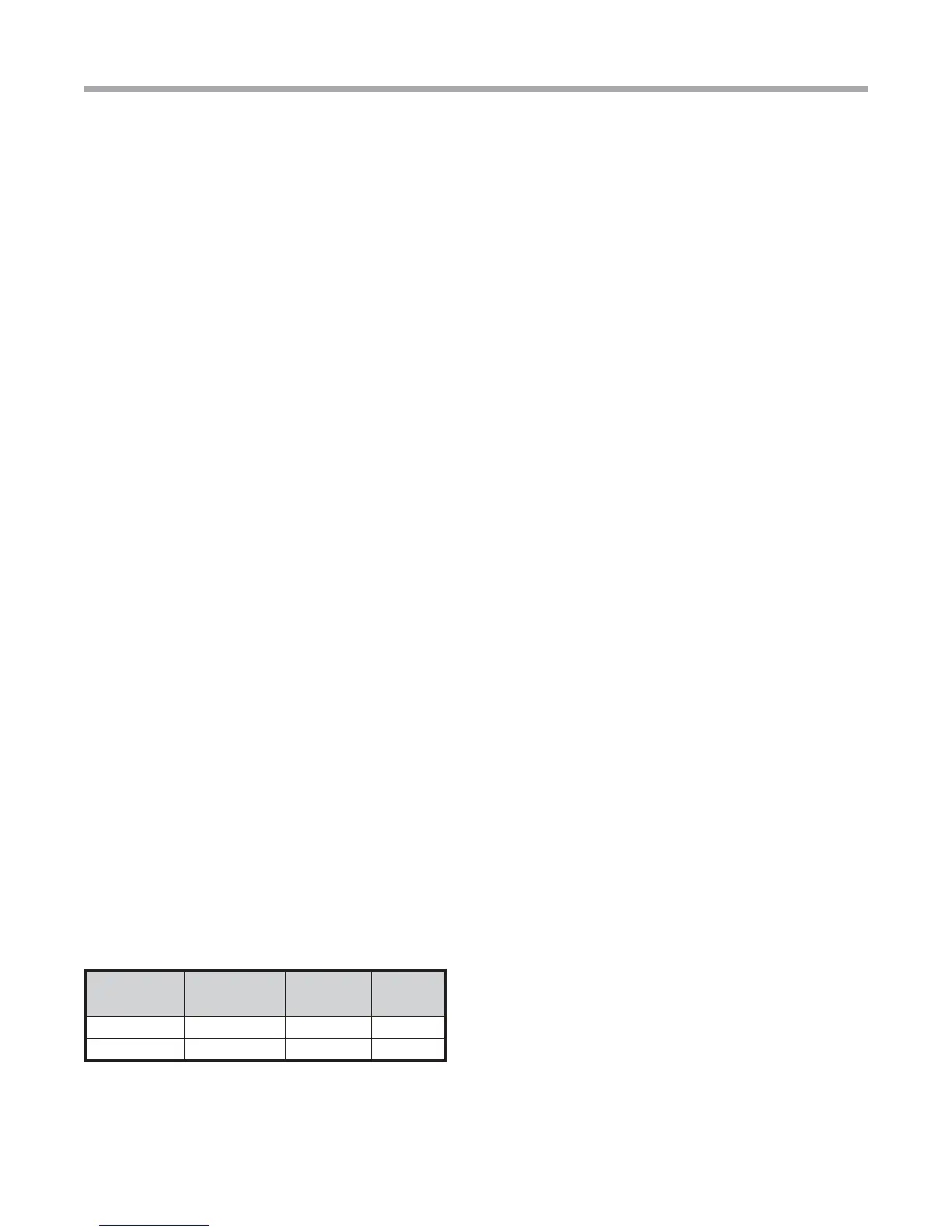

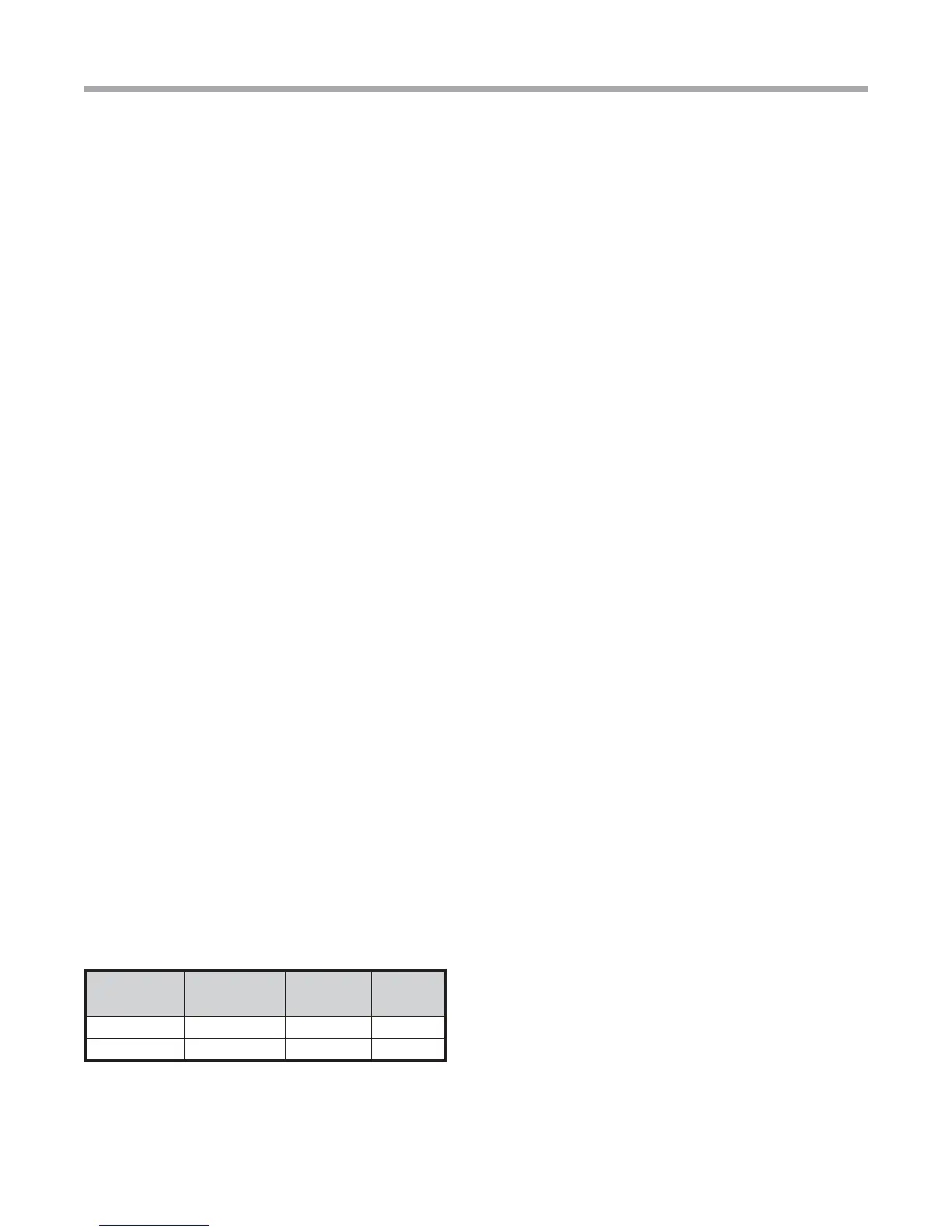

Table X: Internal 3-Way Flushing Valve Data

Model

Flushing

Connection

Straight

Flow Cv

90°

Flow Cv

TE026 - 038 3/4" FPT 25 10.3

TE049 - 072 1" FPT 58 14.5

For example, if a system includes two 2-ton units and four

¾ loop circuits we can calculate the fl ushing pressure drop

as follows. From Table 17 we know that it will take 4 gpm to

fl ush each ¾” circuit. If there is no provision to isolate the

circuits for fl ushing, we will have to fl ush with a minimum of

4 circuits x 4 gpm/circuit = 16 gpm total. A check of other

piping sizes used must be done to ensure that 16 gpm total

fl ow will fl ush all piping.

Pressure drop through the fl ushing valve can be calculated

using the following formula.

∆P = (GPM/Cv)

2

where,

∆P = pressure drop in psi through the valve while fl ushing

GPM = fl ushing fl ow in gallons per minute

Cv = valve Cv in fl ushing mode

We know from Table X that the Cv for the fl ushing valve in

a TE026 is 10.3 in the fl ushing mode (90° fl ow). Therefore,

∆P = (GPM/Cv)

2

= (16/10.3)

2

= 2.4 psi per valve (there are

two fl ushing valves). So long as the fl ushing pump is able to

provide 16 gpm at the fl ushing pressure drop of the loop plus

the 2.4 x 2 valves = 4.8 psi of the fl ushing valves, the internal

fl ushing valves may be used. If the fl ushing pump is not able

to overcome the pressure drop of the internal fl ushing valves,

then larger external fl ushing valves must be used.

Multiple Units with Internal Flow Controllers

The simplest multiple unit system is one with two (or more)

units utilizing internal Flow Controllers with no external

pumps or fl ushing valves. In this case the units are piped

in parallel and use the internal fl ushing valves to fl ush the

system. The variable speed pump includes an internal check

valve to prevent back (short circuiting) fl ow through the units.

In this case, fl ush the loop through the internal fl ushing

valves in the unit farthest from the loop fi rst. Once the loop is

fl ushed, then change the internal fl ushing valves to fl ush the

heat pump. Next, move the fl ushing cart to the next closest

unit to the loop.

Again, fl ush the loop through the internal fl ushing valves.

This is important as there may be air/debris in the lines from

this unit to the common piping. Once fl ushing begins the air

will be move into the loop and will need to be fl ushed out.

After the loop is fl ushed through the second unit, change the

fl ushing valves to fl ush the second unit. This process should

be repeated for additional units working from the farthest

from the loop to the closest to the loop.

This type of application can generally be employed for

systems to 12 tons depending on loop design. However, it

is important perform appropriate calculations to confi rm that

the variable speed pump can provide adequate fl ow through

all heat pumps against the loop head when all units are

operating.

Loading...

Loading...