Page 6 BB6100 Operating Manual

1.6 Risk Assessment Checklist

Use these checklists as part of your risk assessment:

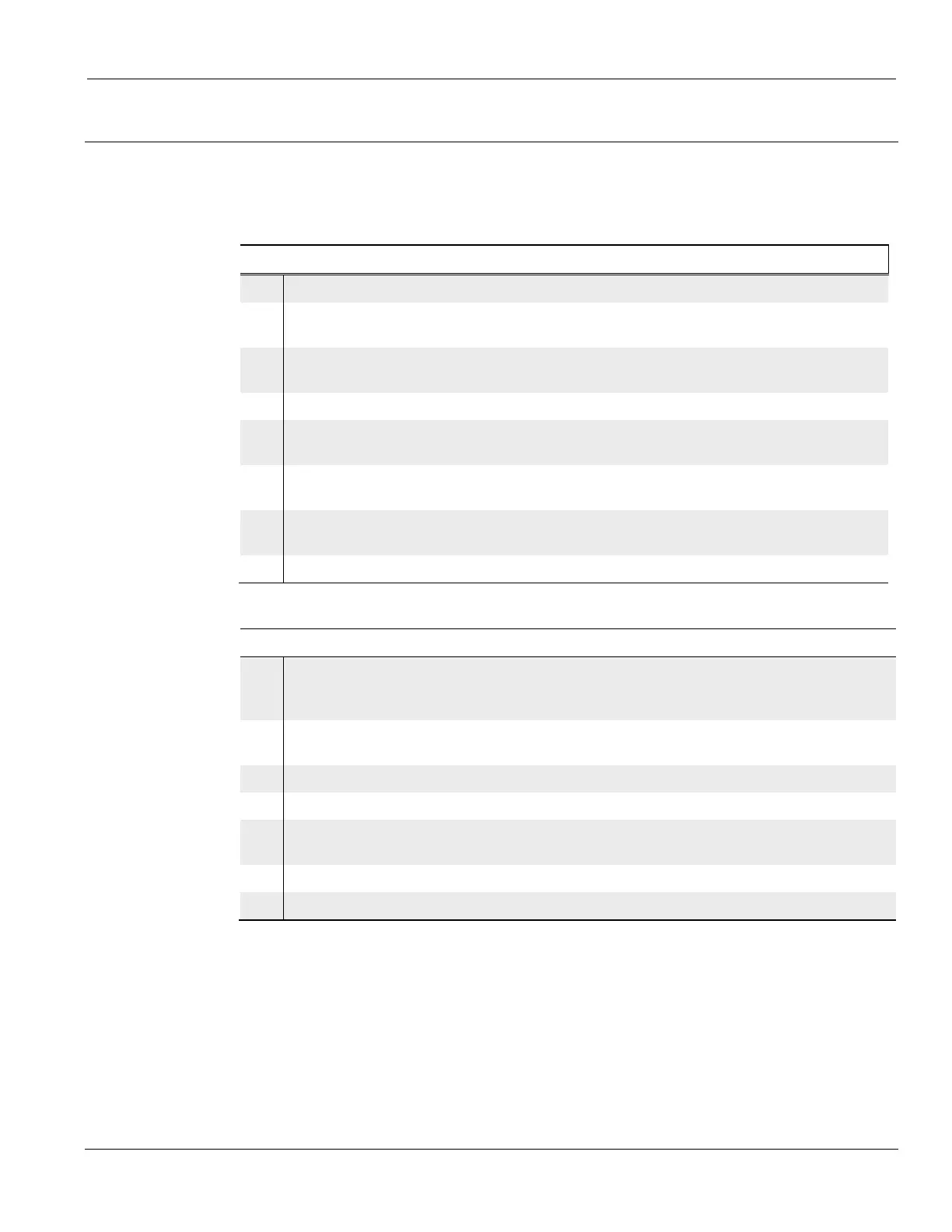

TABLE 1. RISK ASSESSMENT CHECKLIST BEFORE SET-UP

Before Set-up

I took note of all the warning labels on the machine.

I removed or mitigated all identified risks (such as tripping, cutting, crushing,

entanglement, shearing, or falling objects).

I considered the need for personnel safety guarding and installed any necessary

guards.

I read the Setup section on page 15.

I created a lift plan, including identifying the proper rigging, for each of the setup lifts

required during the setup of the support structure and machine.

I located the fall paths involved in lifting and rigging operations. I have taken

precautions to keep workers away from the identified fall path.

I considered how this machine operates and the best placement for the controls,

cabling, and the operator.

I evaluated and mitigated any other potential risks specific to my work area.

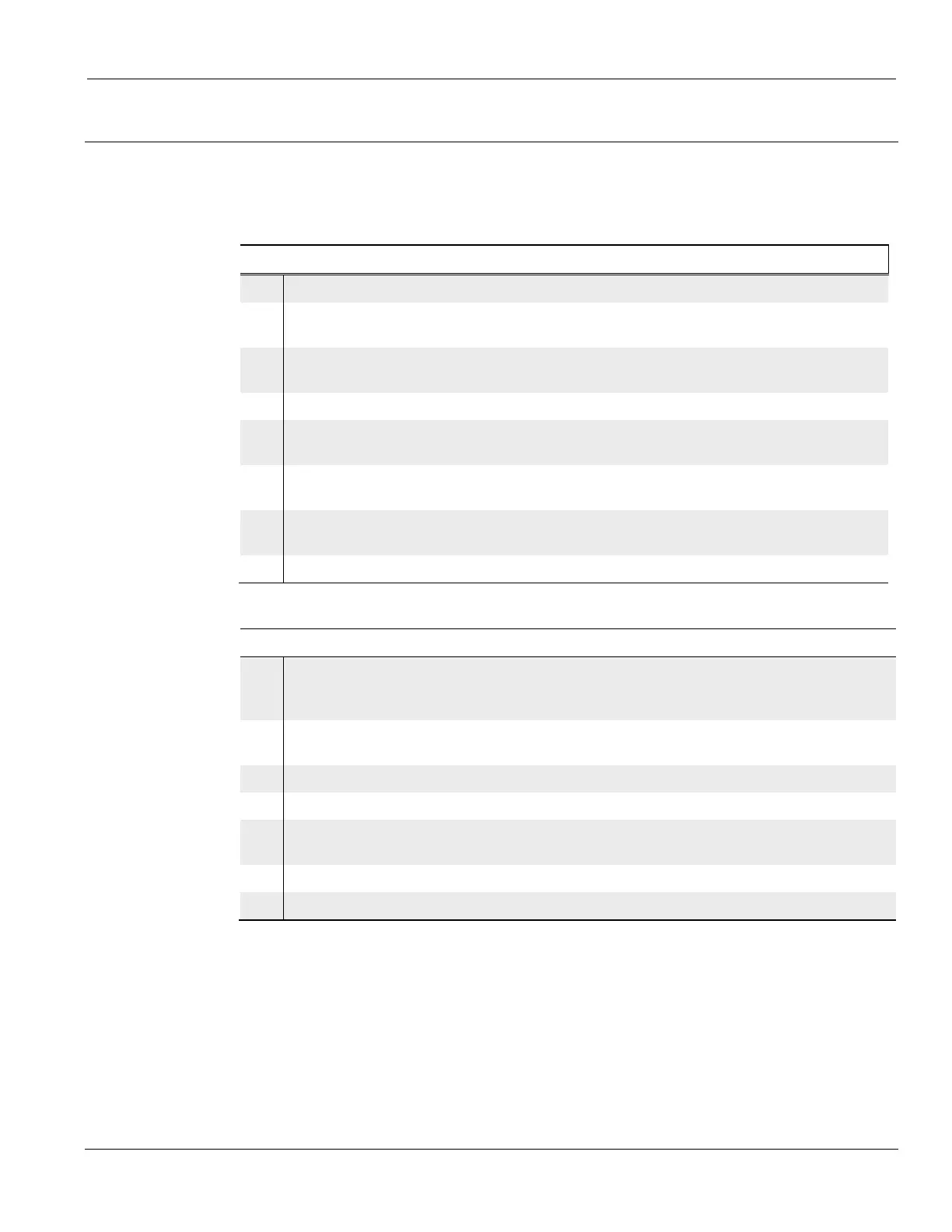

TABLE 2. RISK ASSESSMENT CHECKLIST AFTER SET-UP

After Set-up

I checked that the machine is safely installed (according to the Setup section) and

the potential fall path is clear. If the machine is elevated, I checked that the machine

is safeguarded against falling.

I identified all possible pinch points, such as those caused by rotating parts, and

informed the affected personnel.

I planned for containment of any chips or swarf produced by the machine.

I followed the Maintenance section with the recommended lubricants on page 49.

I checked that all affected personnel have the recommended personal protective

equipment, as well as any equipment required by the site or other regulations.

I checked that all affected personnel understand the danger zone and are clear of it.

I evaluated and mitigated any other potential risks specific to my work area.

Loading...

Loading...