P/N: 57017, Rev. 3 Page 31

3.8.1 Setting the Axial Feed Rate

The feed potentiometer controls the axial feed rate. Turning the knob

counterclockwise decreases the feed rate; turning the knob clockwise increases the

feed rate.

Axial feed rate is adjustable and variable from 0.010–0.500" (0.25–13 mm) per

minute.

3.9 Tool Head Setup

Do the following:

1. Check for lead screw endplay (loose axial lead screw nuts)

2. Attach carrier assembly, lifting eyes + drive key to boring bar

3. Adjust brass shoes for 0.001-0.002 clearance. (Note: Adjust for contact of each

pad against the boring bar, and back off 10 degrees for 0.0015 clearances).

4. Spray with antirust lubricant.

The boring and facing heads require a tool carrier to mount them to the boring bar.

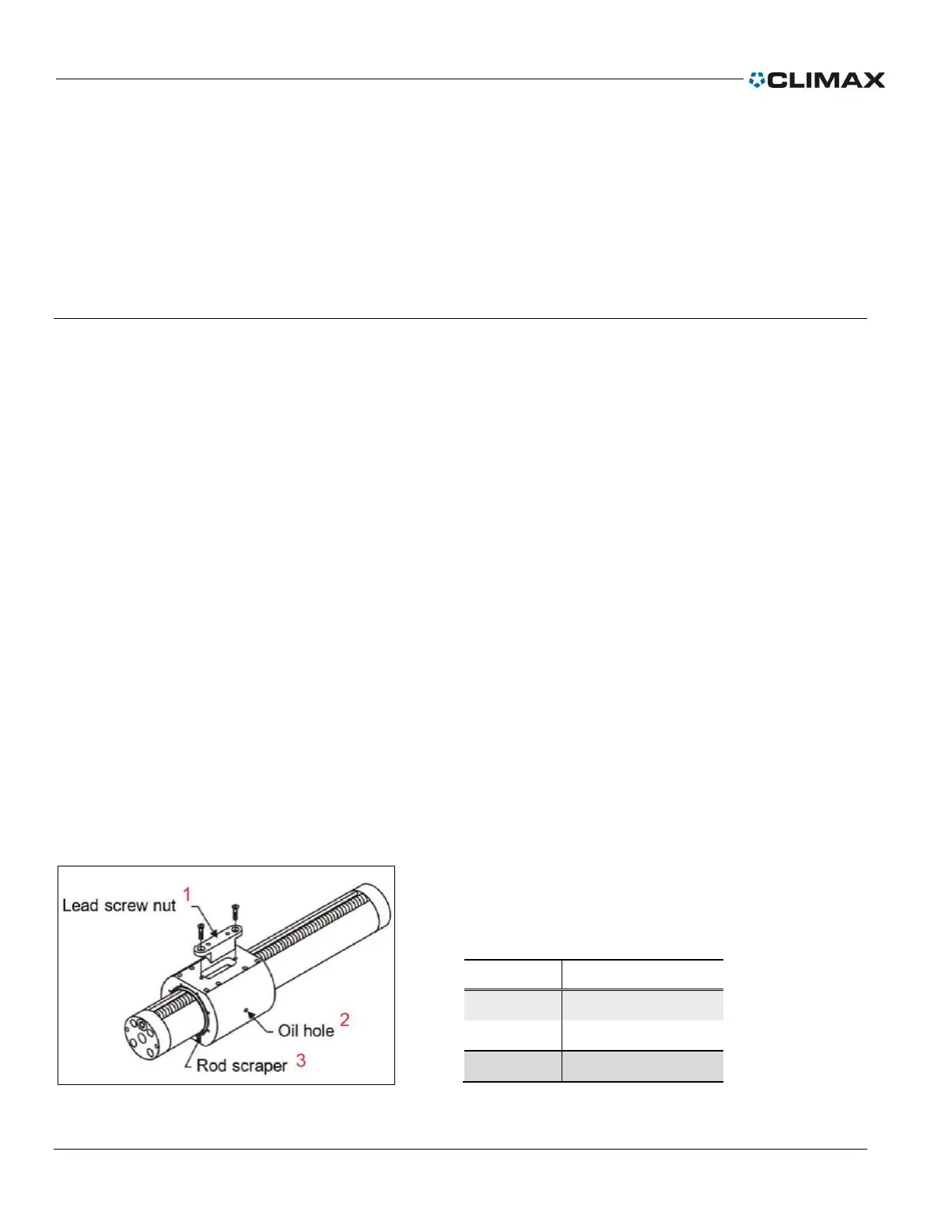

3.9.1 Small bore tool carrier setup

Do the following to mount the tool carrier:

1. Check the bar for nicks, burrs, or cuts. Smooth the bar if necessary. A bar with

nicks, cuts or gouges can damage mating parts, including the tool carrier and

RDU, beyond repair. Clean the bar with solvent to remove dirt and chips.

2. Mount the axial lead screw nut to the top of the tool carrier. Tighten the mounting

screws.

3. Be sure the scraper halves are mounted securely to the ends of the tool carrier.

4. Mount the tool carrier onto the boring bar. Be sure the lead screw nut engages the

lead screw.

5. Tighten the socket-head cap screws.

6. Lightly oil the boring bar and lead screw so the tool carrier will move freely.

Loading...

Loading...