B-15

Welding

GLC 353/503/553 MC3

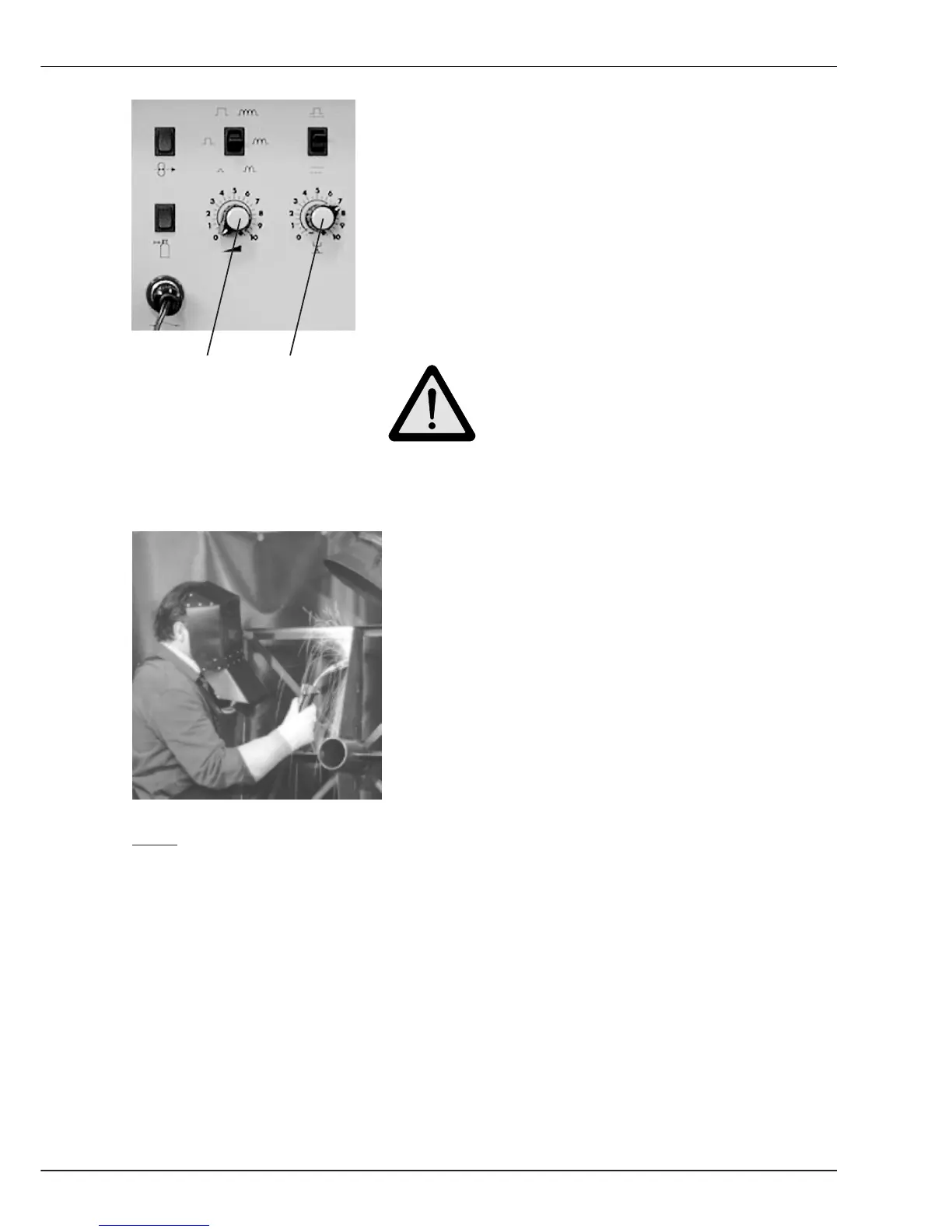

- Select the required Arc output by turning

Potentiometer 1 on the wire drive operation panel.

The resulting values for Wire feed speed and

Welding current set value can be read on

Display 1 and 2 on the power source.

- Begin welding.

Poti 1 Poti 2 Caution!

Protect eyes and skin against arc

radiation! Wear protective clothing !

- Turn Potentiometer 2 to adapt the Arc length to

the set arc output.

- Carry out test welds and optimize the settings on

Potentiometer 1 and 2.

- The actual weld parameters voltage and current are

shown on Display 1 - position Volt and on Display 2

- position Ampere.

Note: Set Display 1 on position mm. The display shows a plate thickness which can

be welded with the set arc capacity. This is only an approximate value which

has to be adapted during production !

If you select A

Hold

on Display 2 the maximum welding current used during

welding can be read at the end of the welding process.

B2.2 MIG-MAG Normal Synergic

Loading...

Loading...