Page 24

UNIT HEATER

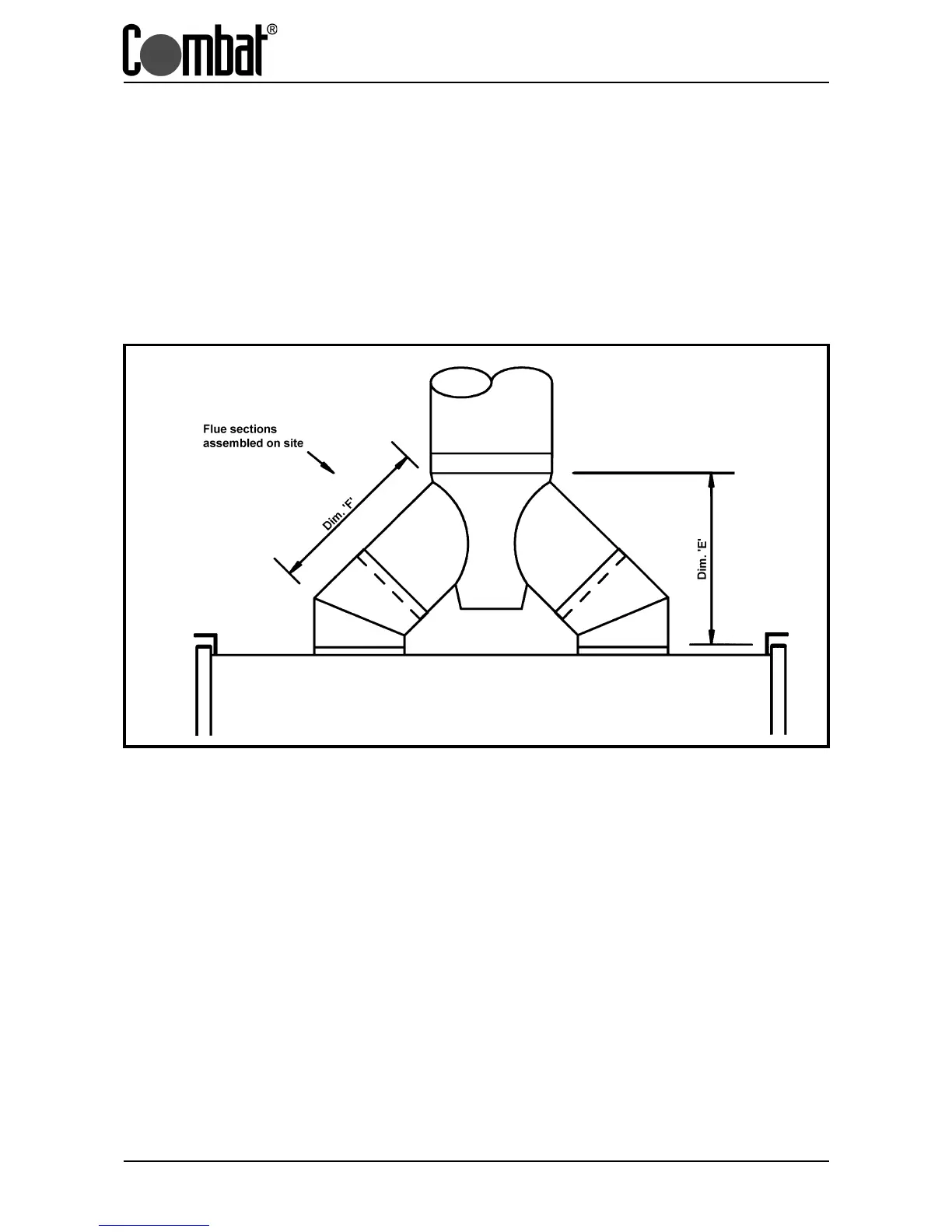

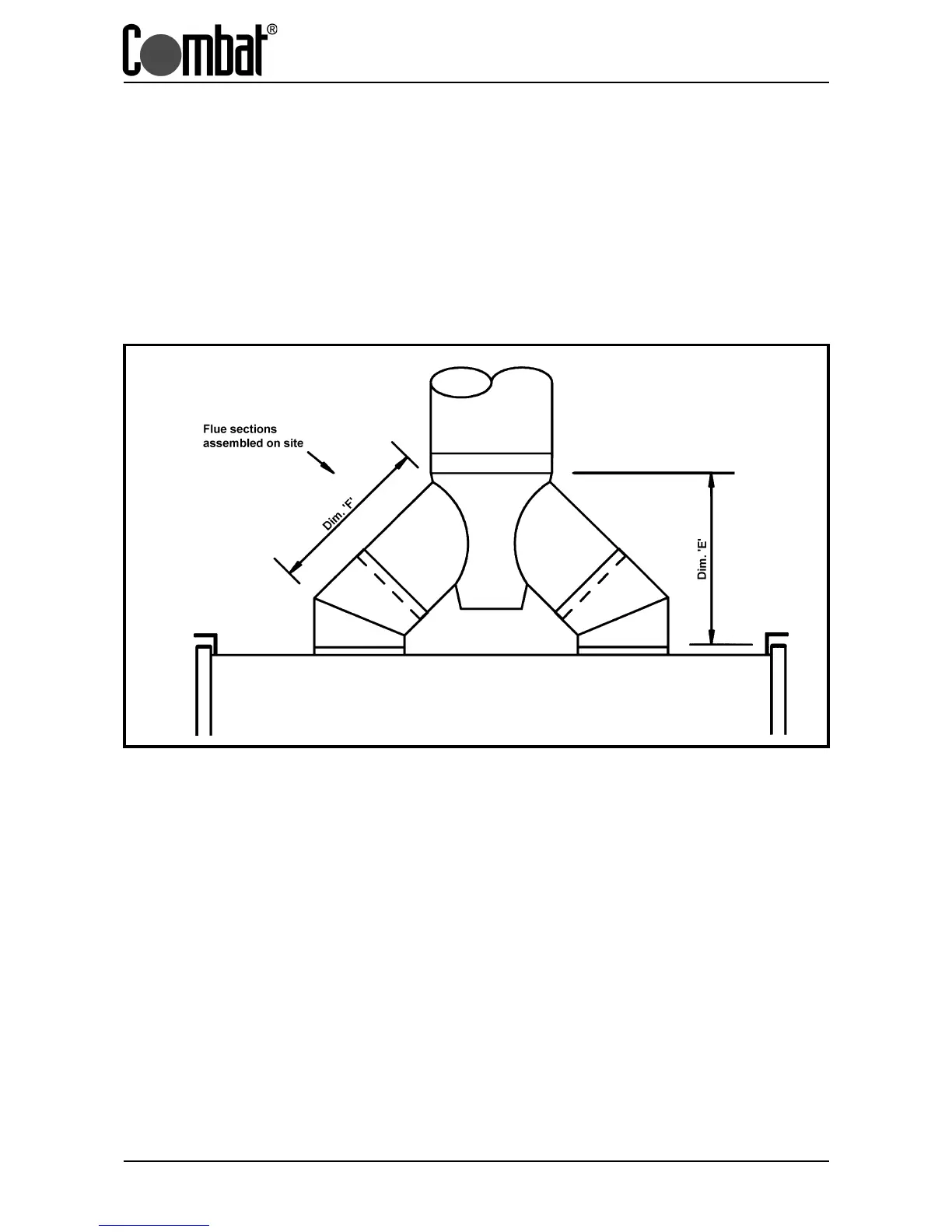

Fig 3.2 Flue assembly of models 340 and 380 only

3.5 Air Supply

It is important to ensure that there is adequate air supply at all times for both combustion and heating

requirements. Particular attention must be paid to this point when the heater is installed in a separate

room. Ventilation should prevent the Plant room temperature exceeding 32°C and any negative air

pressure within the room containing the heater.

Any plant room containing air heaters will require permanent air vents direct to outside air in compliance

with BS 6230.

Most traditional building constructions will provide air changes of at least 0.5/h without the need for

ventilation openings. In the case of a building having an air change rate less than 0.5/h, low level

ventilation will be necessary in accordance with B.S.6230.

If the flue passes through a wall or ceiling of combustible material it must be enclosed by a sleeve of

noncombustible material and be separated from the sleeve by at least a 25 mm air gap. The temperature

of any combustible material near the flue or heater must not exceed 65°C when the heater is in operation.

The flue must be at least 50 mm from any other combustible material.

The joints between the flue and the roof or wall must be made good to prevent water ingress.

The joint between the flue and the female spigot of the heater must be sealed using a heat resistant rope

and fire cement.

Dimension E = 405

Dimension F = 372

Loading...

Loading...