4. Design and functioning

21

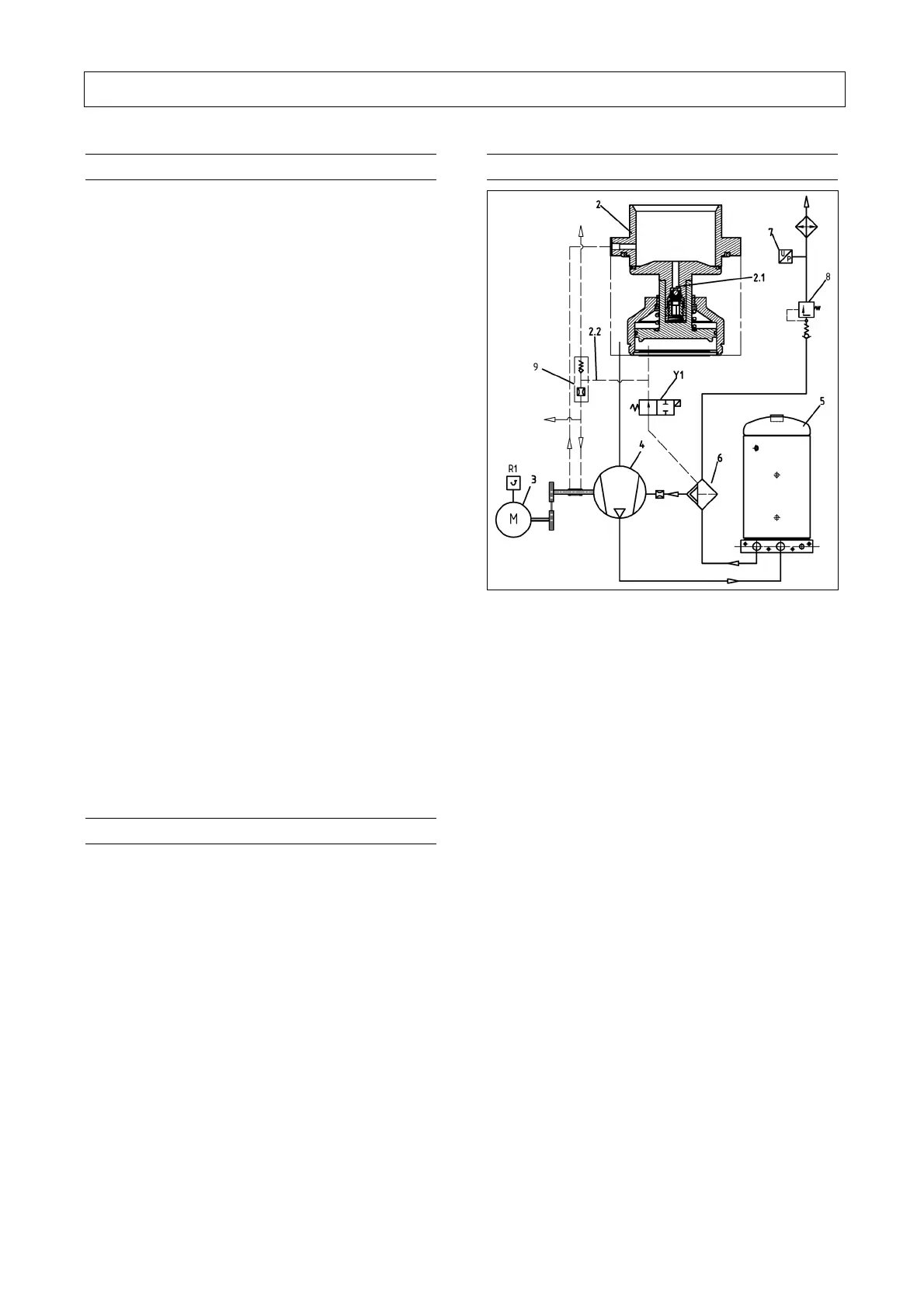

4.3 Oil circuit

The oil flows from the pressure reservoir (- 6 - Fig. 3)

into the oil thermostat (- 17 - Fig. 3). With oil tempera-

tures < 55 °C/131 °F the oil flows via the by-pass of the

oil cooler directly into the oil filter (- 11 - Fig. 3) and is

then injected into the screw compressor (- 4 - Fig. 3).

With oil temperatures of between 55 °C/131 °F and

70 °C/ 158 °F the oil flow is divided and fed into the oil

cooler (- 12 - Fig. 3) and the by-pass.

With oil temperatures above 70 °C/158 °F the entire oil

flow is directed via the oil cooler through the oil filter into

the screw compressor.

The oil separated by the oil separator element

(- 7 - Fig. 3) is fed through an oil scavage line to the

screw compressor.

The entire oil circulation is based on a differential

pressure in the system. Considering the pressure

difference of approx. 2 bar/29 PSI within the oil circuit,

the oil is then injected into the screw compressor with

approx. 8 bar/116 PSI at a reservoir pressure of e.g.

10 bar/145 PSI.

When the screw compressor is in the off-load mode, a

sufficiently high pressure differential and thus the

required oil injection quantity is achieved owing to the

fact that when the intake regulator (- 2 - Fig. 3) is

closed, a vacuum pressure occurs in the intake

connection.

Excess pressure of approx. 1.5 - 2 bar/22 - 29 PSI

(residual pressure) is produced in the pressure

reservoir at the same time.

4.4 Air circuit

The intake air passes through the intake filter (- 1 - Fig. 3)

and the intake regulator (- 2 - Fig. 3) into the screw

compressor (- 4 - Fig. 3). During the compression

process, the intake air is cooled via the injected oil, and

the developed air/oil mixture flows tangentially into the

pressure reservoir (oil reservoir) (- 6 - Fig. 3). After pre-

separation and subsequent fine separation by the

separator element (- 7 - Fig. 3), the compressed air with

a low oil content is fed via the minimum pressure valve

(- 15 - Fig. 3) and the air cooler (- 16 - Fig. 3) into the

consumer network.

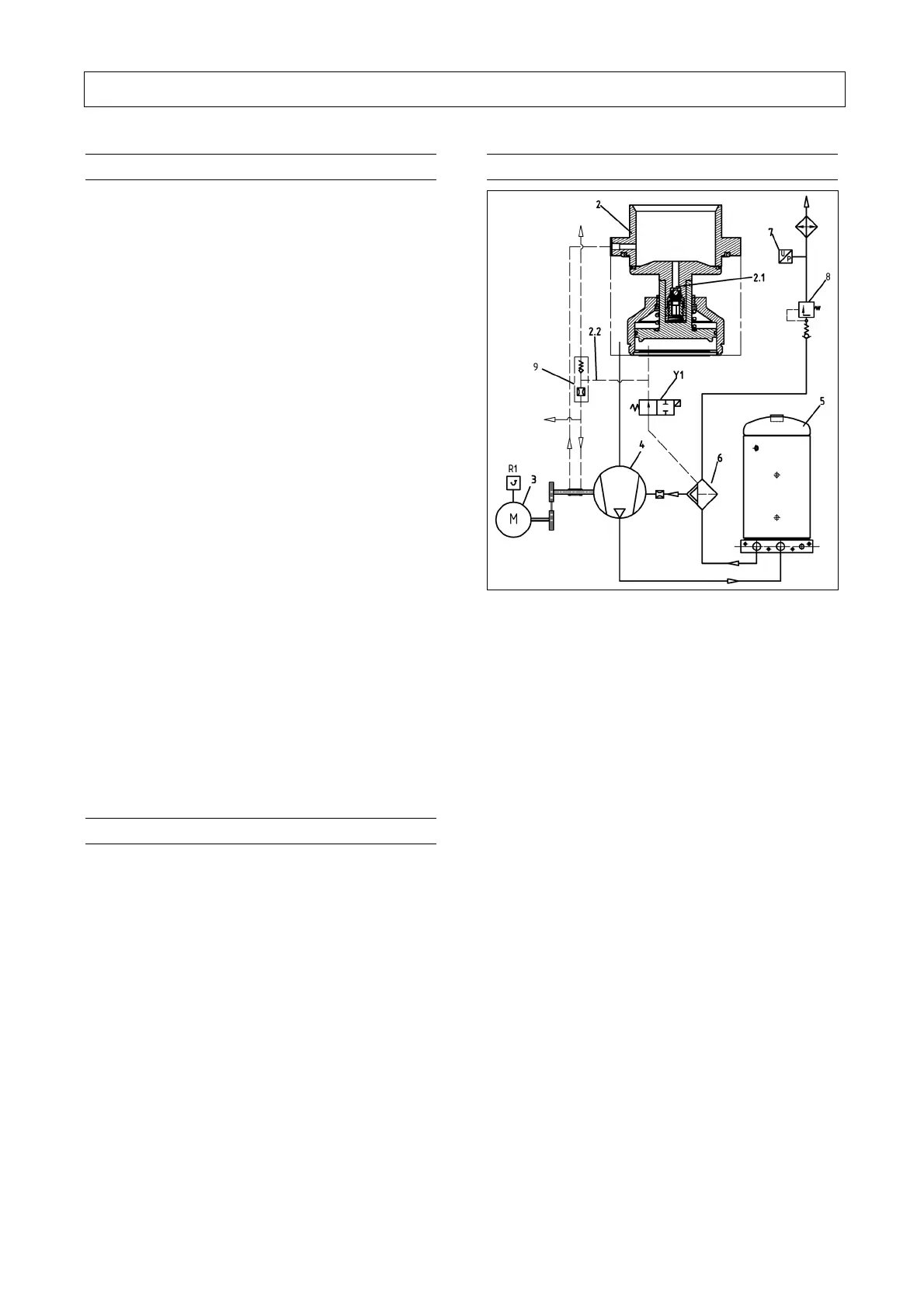

4.5 System control

Fig. 4

4.5.1 System control L07-L11 / L07FS-L11FS

Standstill of the system

• When the system is at rest the intake regulator

(- 2 - Fig. 4) is closed.

• The solenoid valve (Y1 Fig. 4) is de-energised.

• The pressure reservoir (- 5 - Fig. 4) is bled via the

blow-off line (- 2.2 - Fig. 4) and the orifice (-9 - Fig. 4)

into the suction channel.

Starting the system

• The motor (- 3 - Fig. 4) starts up in the Y-mode.

• The compressor extracts a certain volume of air via

a start valve (- 2.1 - Fig. 4). Pressure builds up in

the reservoir and closes the regulator.

• When changing over to Δ operation, the solenoid

valve (- Y1 - Fig. 4) is energised, which blocks the

connection between pressure vessel and intake

regulator.

• The intake regulator opens due to the intake

vacuum pressure. Venting of the control piston

takes place via the blow-off line (- 2.2 - Fig. 4).

• The minimum pressure valve (- 8 - Fig. 4) opens

when the pressure reservoir is approx. 4.5 bar.

• Compressed air is now delivered into the consumer

network.

Loading...

Loading...