5. Transport and installation

24

5 Transport and ins tallation

5.1 Transport

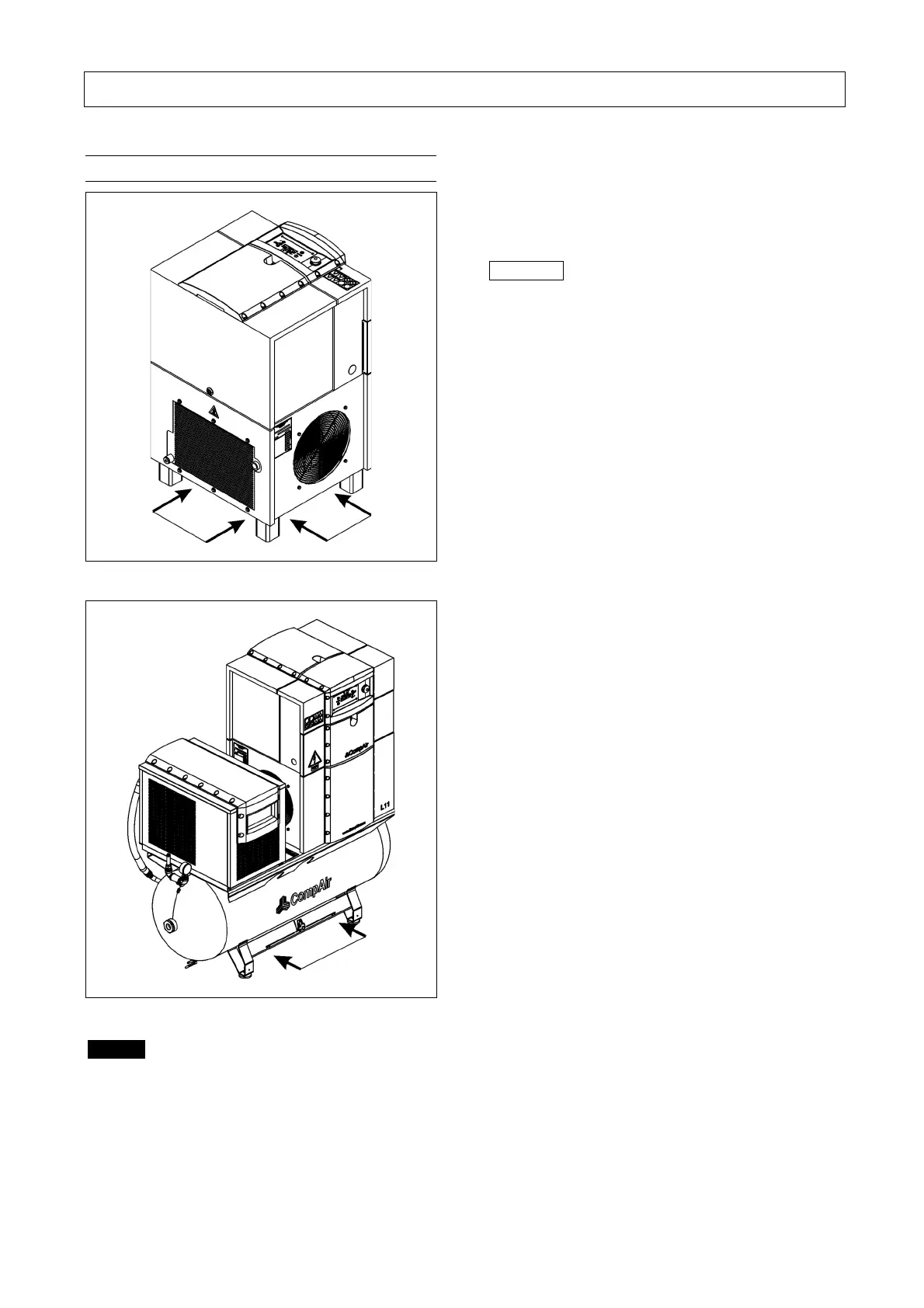

Fig. 6 a

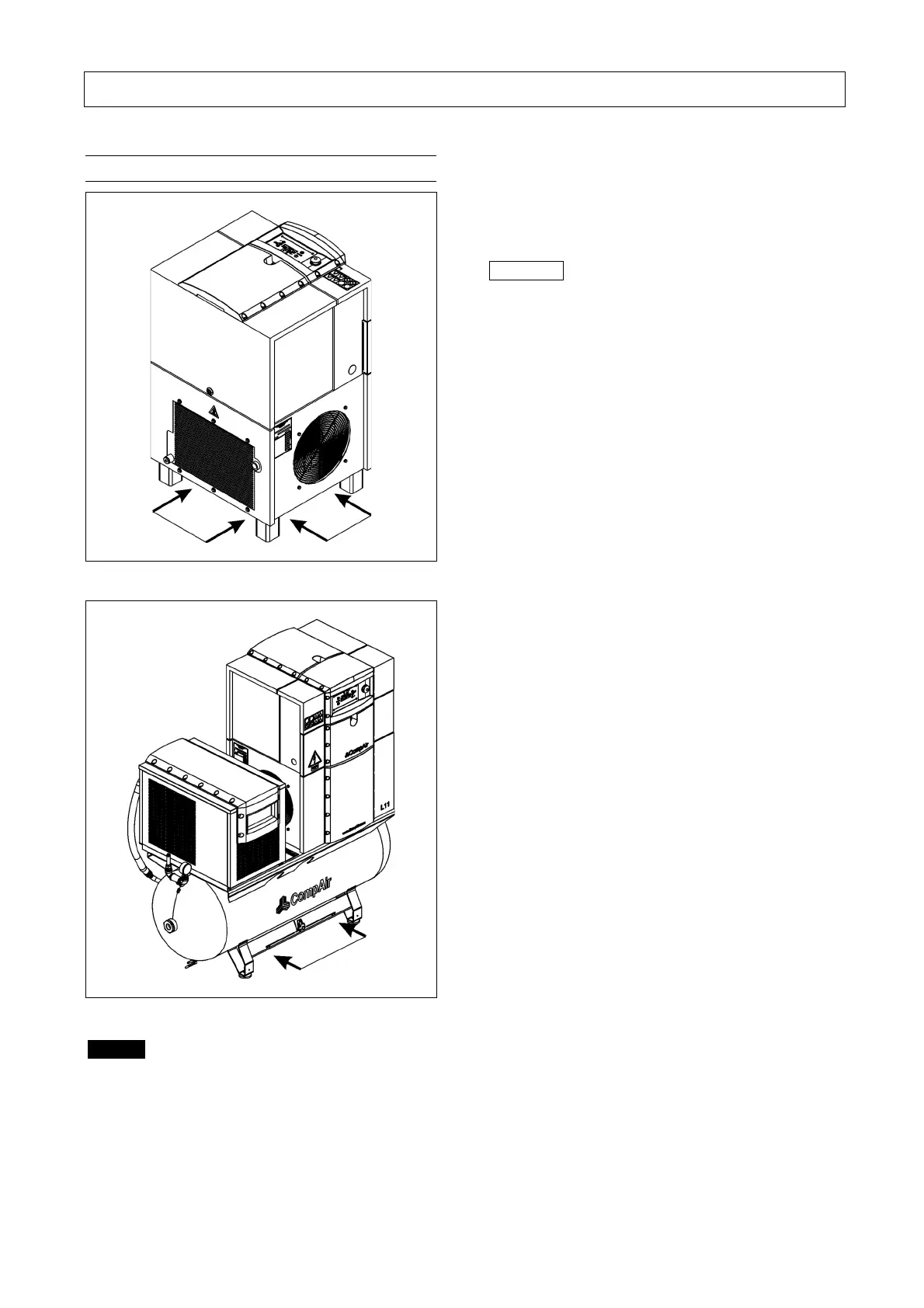

Fig. 6 b

Danger

The compressor must be lifted using a suitable

forklift truck which complies with the local safety

regulations.

The length of the forks must correspond at least to

the width of the unit (see Chapter 11).

Before lifting, all loose or slewable parts of the

machine have to be firmly secured.

It is strictly prohibited to work or stand in the

danger zone of a lifted load.

The proper lifting of the load (according to the

operating instructions of the load suspension

device) has to be ensured.

Important

Never lift or lash the compressor and its hood via

the enclosure. The screw compressor is lifted with

the help of a fork lift truck (Fig. 6). The separation

of the forks and their length must be taken into

account for transportation.

Only use the identified lifting points. Do not slide

the unit when it is standing on the floor.

Weights

The values listed below are approximate values, they

refer to a screw compressor unit including oil fill:

Compressor L07-L11:

Loading...

Loading...