9. Service and maintenance

48

9.9 Changing V-belts/automatic

tensioning system

Danger

Only perform checks and carry out work when the

screw compressor unit is out of operation and

depressurized, electrically isolated and locked off.

Any safety equipment which had to be removed for

the replacement of the V-belt set must be

remounted after completion of this work.

Important

The replacement of a single V-belt is not permitted,

always replace a complete V-belt set.

During the entire service life of the V-belt set, no

readjustment of the automatic V-belt tensioning

system will be necessary.

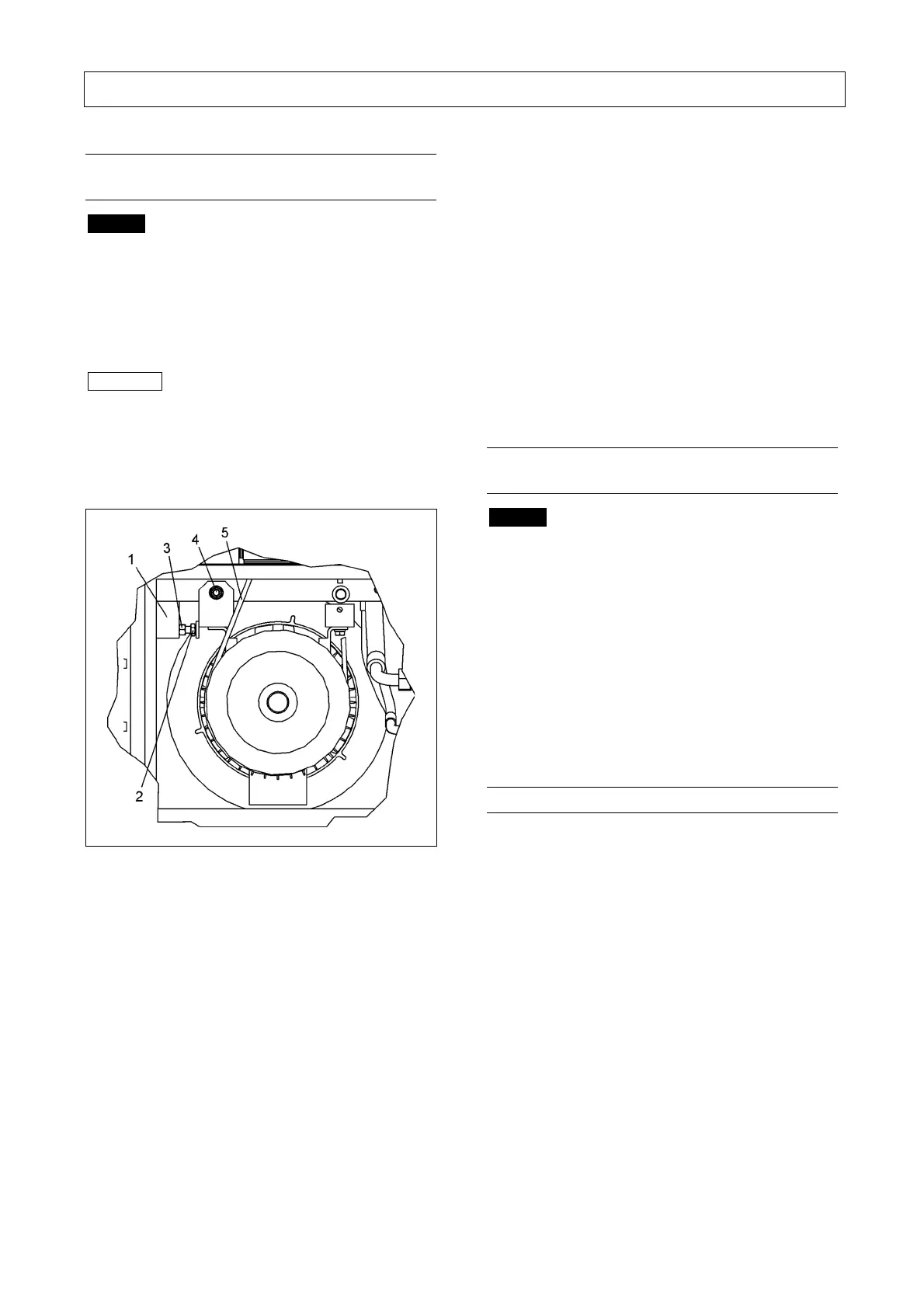

Fig. 22

1 Holder

2 Motion screw

3 Lock nut

4 Rotational axis

5 V-belt set

The V-belt preload needed is specified by the weight of

the motor, which is mounted in a rotary fashion (- 4 -

Fig. 22).

Changing the V-belt is carried out as follows:

• Open front panel

• Lift the motor by turning the motion screw

(- 2 - Fig. 22) counterclockwise until the V-belts are

released

• Clean/degrease the V-belt pulleys

• Replace the V-belt set (- 5 - Fig. 22)

• Screw the belt adjusting bolt back until it reaches

the lock nut (- 3 - Fig. 22). Tighten lock nut on holder

(- 1 - Fig. 22).

• Close the front panel

9.10 Connecting terminals in the switch

cabinet/control transformer setting

Danger

In the case of electric voltage:

•

Actuate STOP button

at the operating panel

•

Set the customer-fitted main power switch to

"O" (OFF).

The connecting terminals in the switch cabinet have to

be checked and, if required, re-tightened during first

commissioning and later on in line with the maintenance

schedule.

The setting of the control transformer must be checked

according to chapter 6.3 “Electrical connection”.

9.11 Fittings

The fittings of the air and oil circuits have to be checked

and, if required, re-tightened according to the

maintenance schedule.

Check the hose and piping for unsealed areas.

Loading...

Loading...