6. Preparations for commissioning

27

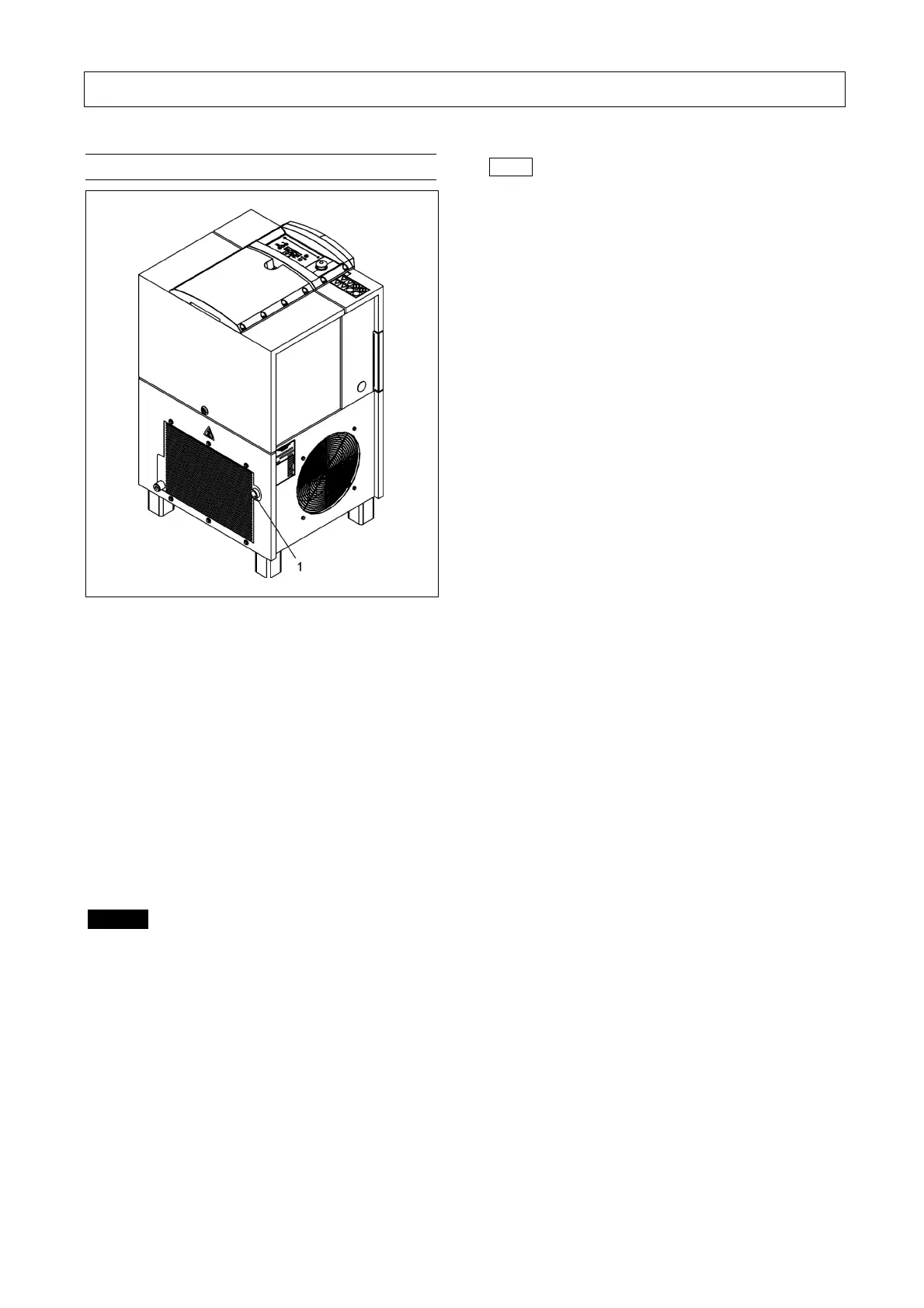

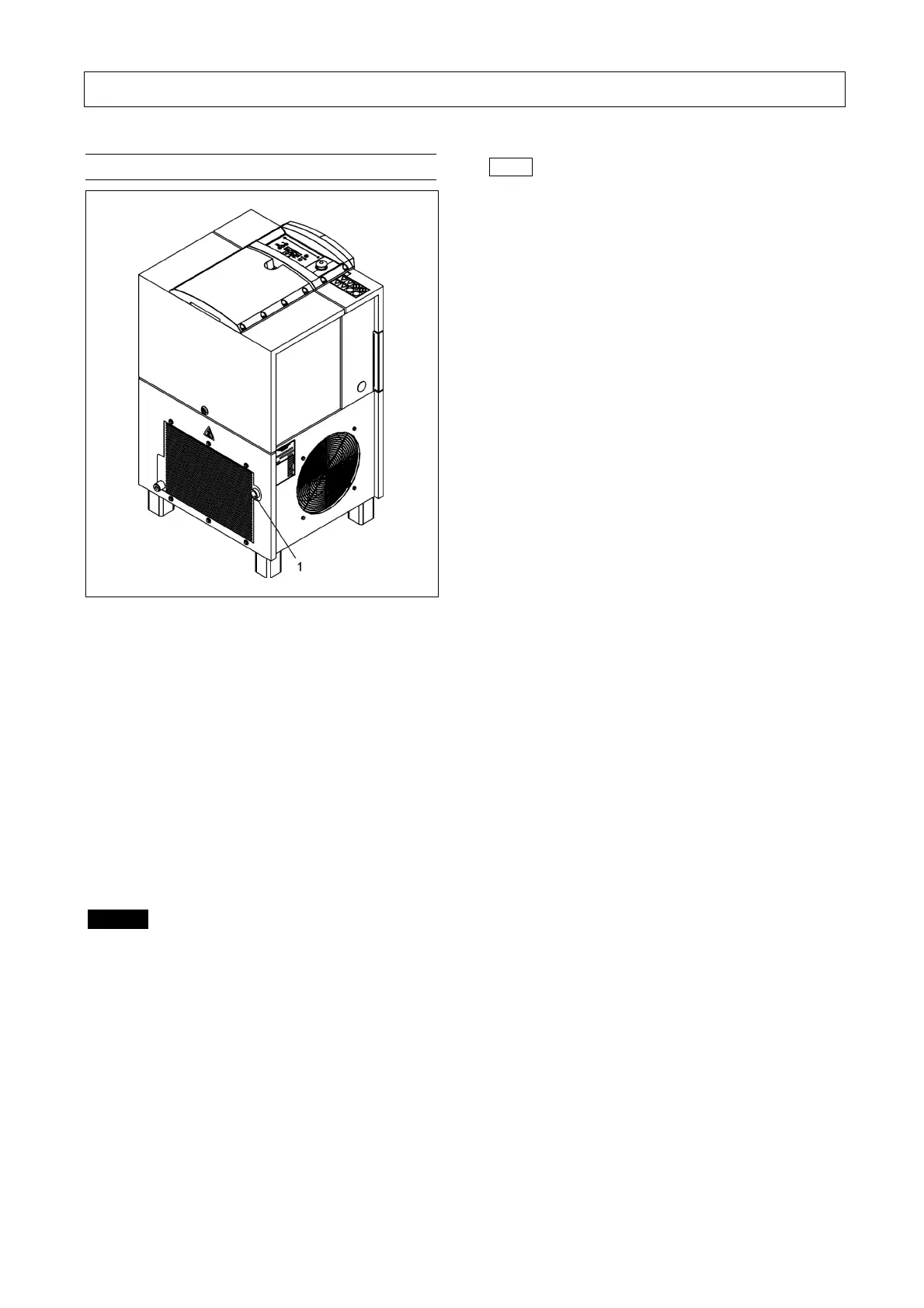

6.2 Compressed air connection

Fig. 9

1 Compressed air connection

The compressed air line system is connected at the

compressed air supply of the screw compressor

( - 1 - Fig. 9).

The AirStation L07(RS) FS-L11(RS) FS series is

connected to the pressure reservoir (-12- Fig. 2b).

For this you should use a flexible connection

(e.g. compressed air hose, compensator).

L07(RS)-L11(RS):

sleeve G 3/4“ (3/4“ NPT)

AirStation L07(RS) FS-L11(RS) FS:

sleeve G 3/4“ (3/4” NPT)

Danger

When connecting the compressor on the mains

side to the compressed air system available at the

customer‘s end, check the operating temperatures

and operating pressures required and examine the

required connecting flange or the connection

thread for proper type, size and functioning

(see Fig. 9).

In the case of connections by means of connecting

hoses, take appropriate measures to prevent

whipping of the loose end in the event that the

hose connection tears off.

Note

After-coolers, separators, collecting reservoirs and the

compressed air lines must be equipped with drain

facilities at their lowest points to drain collected liquids.

These facilities have to be fitted to allow the observance

of the draining of such liquids.

Hand-operated drain facilities have to be actuated in

accordance with the operating instructions.

Automatic drain facilities have to be checked for proper

function at regular intervals. When draining

condensates into a collecting line, which also collects

the condensate from other machines, make sure that

the collecting line is free from back pressure at all lines.

Condensate may contain oil! When draining

condensate, observe the corresponding regulations for

waste water disposal.

Loading...

Loading...