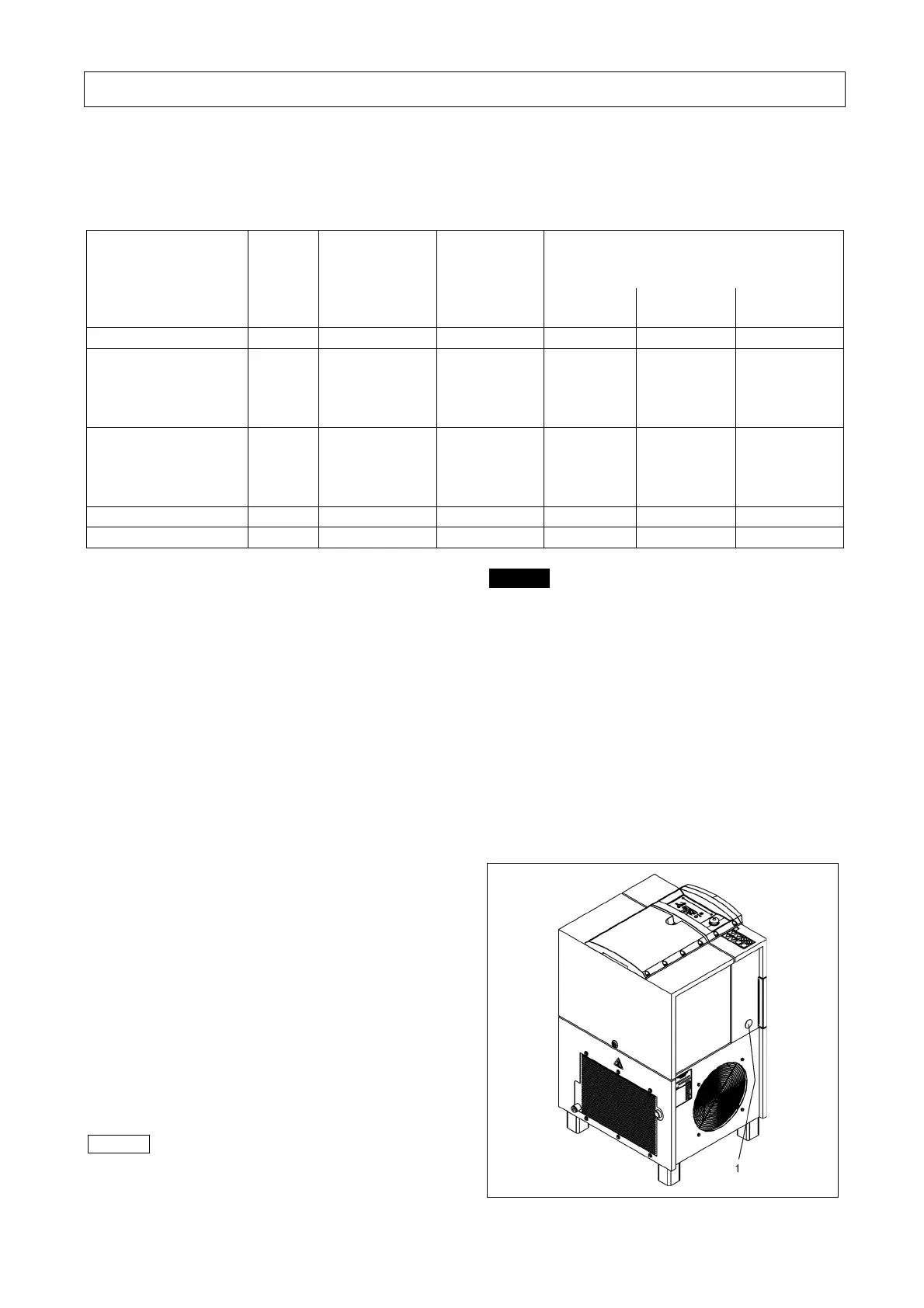

An adequate electrical power supply of the correct

voltage must be provided. All control enclosure wiring

has been completed at the factory.

The electrical supply should be equipped with a fused

line disconnect switch or circuit breaker so that

electrical power may be disconnected while the unit is

being serviced.

The fuse line disconnect should be located and moun-

ted in accordance with all state, local, and national

regulations.

The unit must be properly grounded to provide adequa-

te ground fault protection. As a guide, it is suggested

that the ground wire be equal in size to one of the con-

ductors which feeds the compressor motor circuit. Make

certain the ground wire connections are clean and tight.

The wire used to feed the compressor circuit should be

selected and sized based on the following conditions:

1. Motor full load amperage plus service factor.

2. Ambient temperature in the area where the wire is

located.

3. Length of wire

4. Insulation type

This information may be found in the latest edition of

the National Electrical Code.

When installing a unit in a "Hazardous Location"; that is

in a location where fire or explosion is a definite hazard,

refer to the appropriate section of the National Electrical

Code for further information.

Caution

IN ALL CASES, THE LOCAL, STATE, AND NATIONAL

ELECTRICAL CODES MUST BE STRICTLY

FOLLOWED.

Danger

The power supply to the compressor side has to be

fitted for industrial equipment and fulfilling the

requirements of NFPA 79. To avoid strong damages

and fire on the power electric components, any

kind of operation outside of the stated limits of

NFPA 79 is inadmissible.

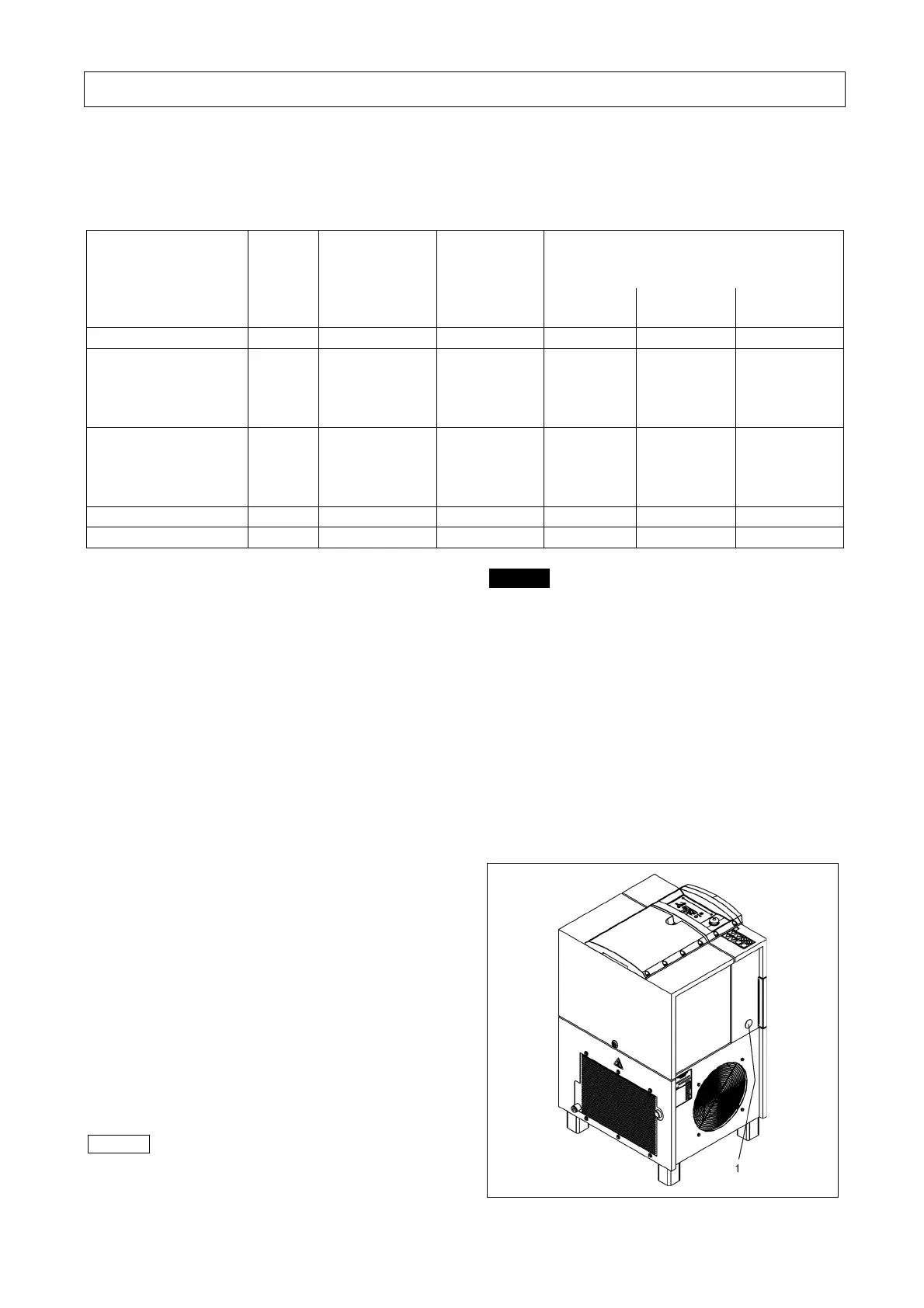

To establish an electrical connection, proceed as

follows:

Route the supply cable through the cable gland

(- 1 - Fig. 10) on the control cabinet and tighten screws.

Connect the supply line to the connecting terminals as

shown in the circuit diagram.

Fig. 10

Loading...

Loading...