9. Service and maintenance

45

In this case the oil must be analyzed to check the

permissible length of time that the oil can be used (see

also chapter 9.15). Under no circumstances should the

oil be used beyond its design life.

9.5 Change of oil filter cartridge

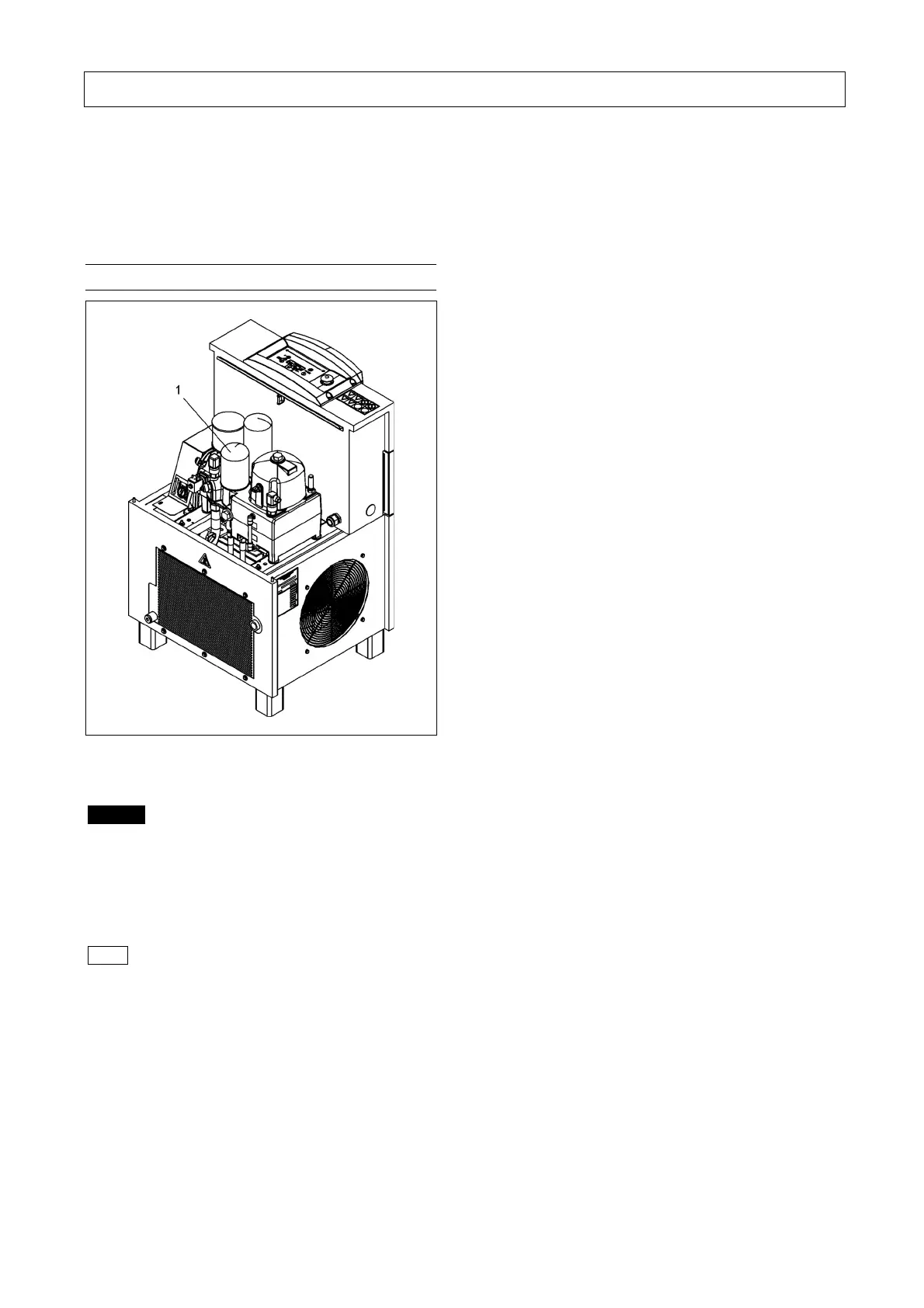

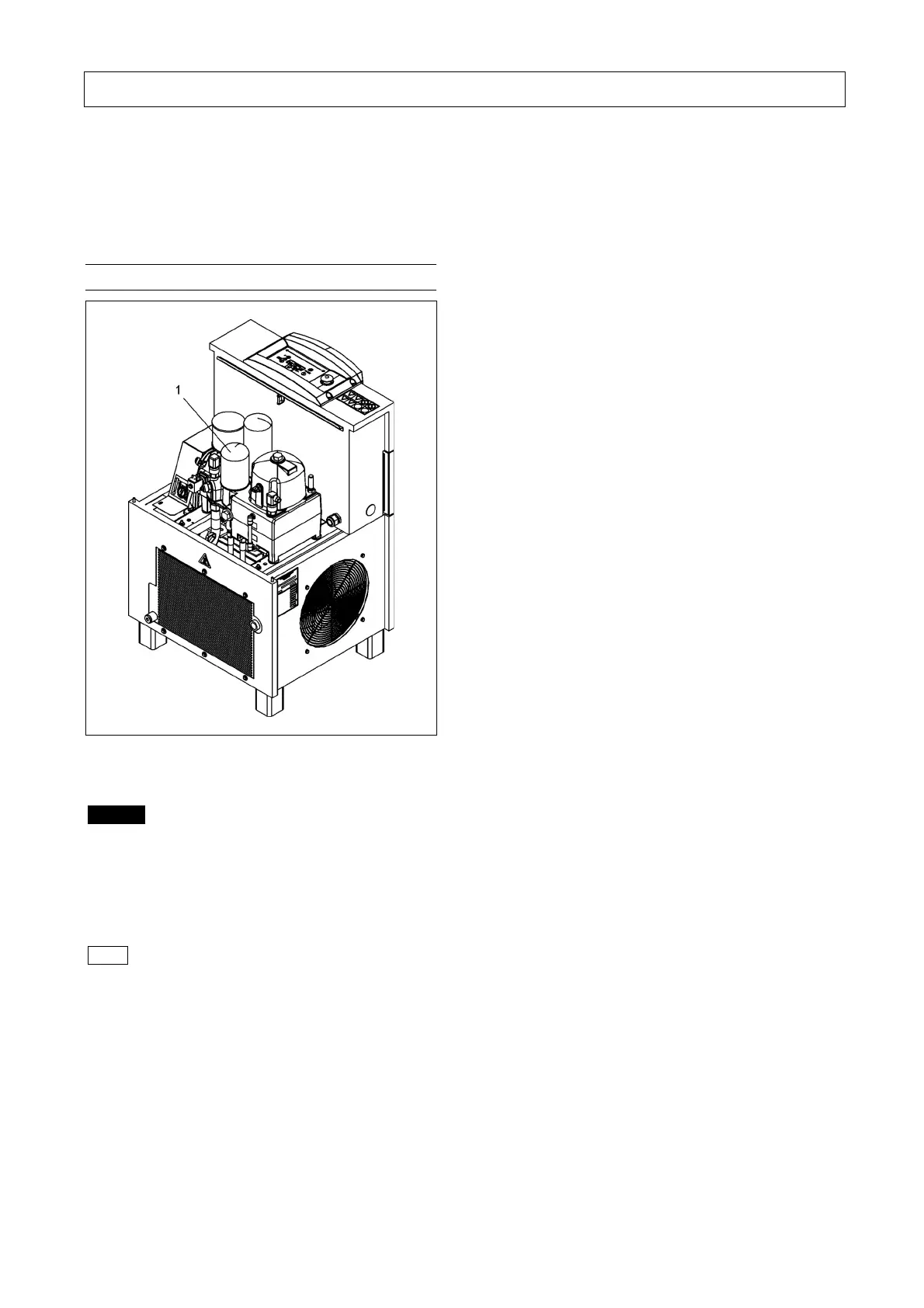

Fig. 18

1 Oil filter cartridge

Danger

Only replace the oil filter cartridge when the screw

compressor unit is out of operation and

depressurized!

Be careful with hot oil: Danger of scalding! Do not

spill oil!

Note

Dispose of the oil filter cartridge in line with the

regulations - special waste ! Check for leakage!

For the changing intervals, see the maintenance

schedule.

Change the oil filter cartridge as follows:

• Switch the screw compressor unit off and ensure

that it is depressurized, electrically isolate and

locked off.

• Wait at least 5 minutes for the oil to settle and for

the air to disperse.

• Unscrew the oil filter cartridge ( - 1 - Fig. 18) using

an appropriate tool

• Dispose of the oil filter cartridge according to the

regulations

• Oil the gasket of the new oil filter cartridge slightly

• Screw on the new oil filter cartridge and tighten

manually (take notice of the instructions on the oil

filter cartridge)

• Check for leakage

• Check oil level (see chapter 6.5)

• If required, top up oil.

Changing intervals for oil filter cartridge

The operating conditions (e.g. coolant temperatures),

the operating modes and the quality of the intake air

(e.g. content of dust, content of gaseous foreign matter

such as SO2, solvent vapours, etc.) have a strong

influence on the service life of the filters (air filters, oil

filters, fine separators).

Where such conditions exist the filter element may

require changing more frequently.

Loading...

Loading...