The control is mounted on the front of the I/O station. Inside

is a processor with base, containing up to 8 input/output mod-

ules. The number of input and output modules will vary with

the number of vacuum receivers and conveying options.

WHAT IS THE

B32?

Basic 32 Loader Control UGC007/0702

2-2 DESCRIPTION

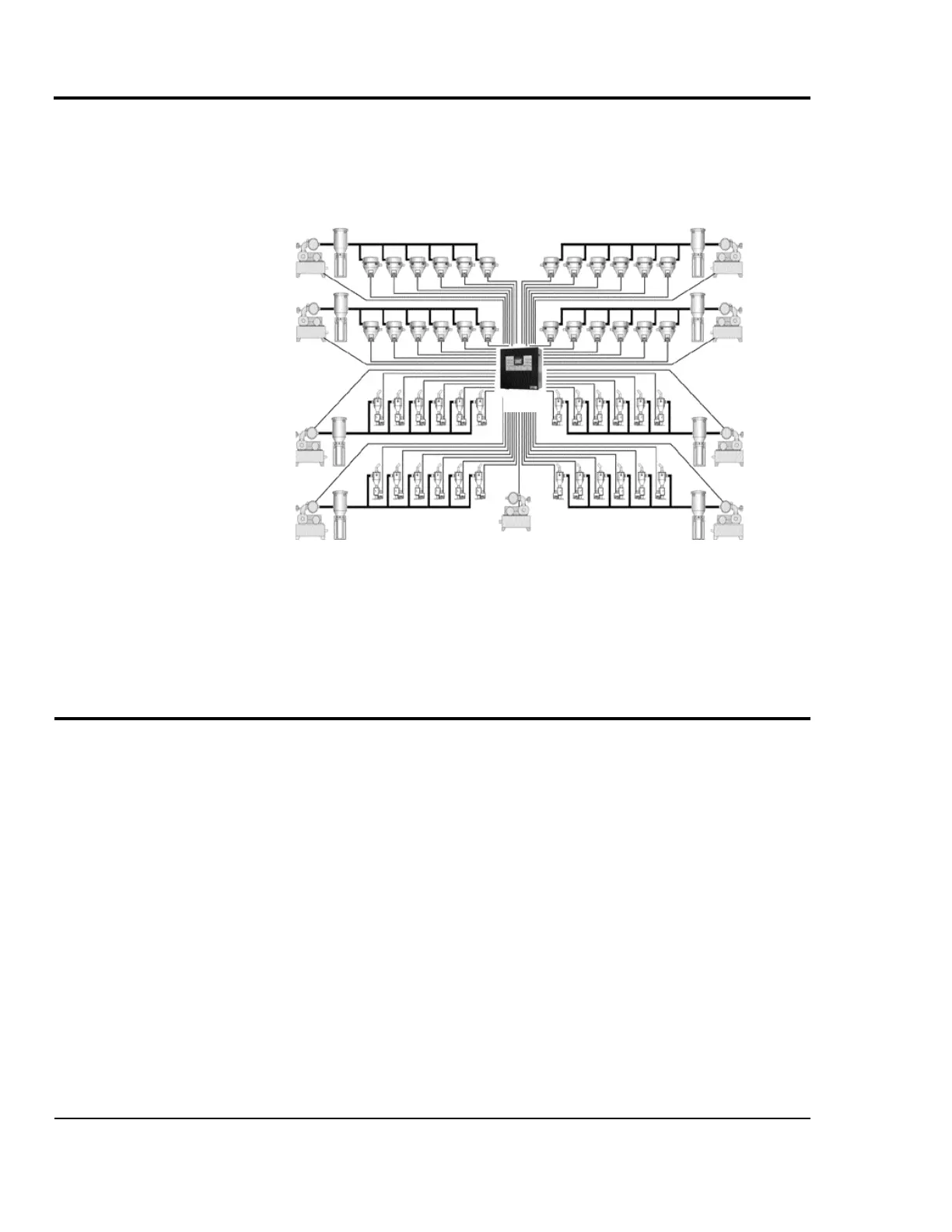

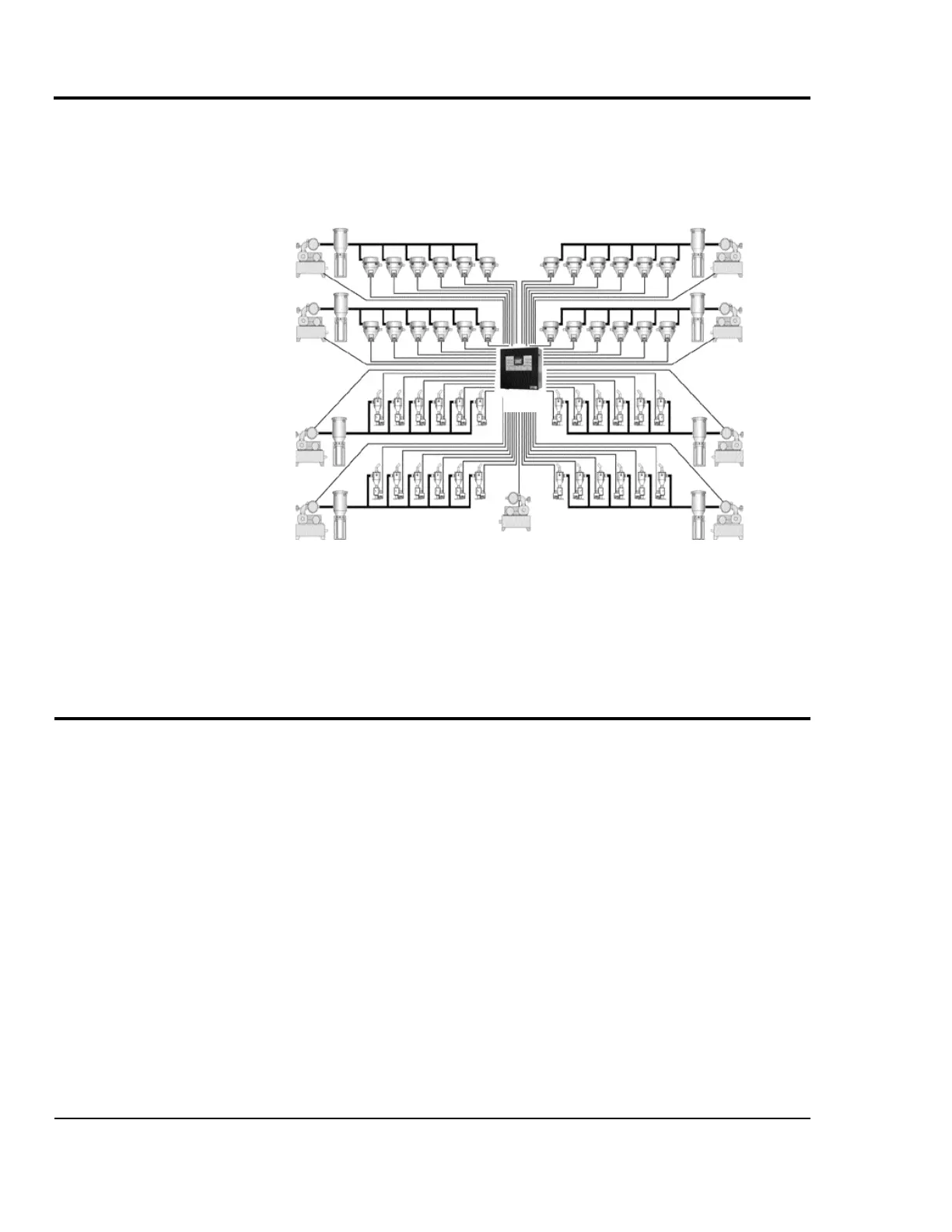

TYPICAL

APPLICATIONS

Backup

Pump

Pump

System 1

Pump

System 2

Pump

System 4

Pump

System 3

Pump

System 5

Pump

System 6

Pump

System 8

Pump

System 7

B32

The Basic 32 has been designed for basic conveying applica-

tions.

Loader-pump assignments are completely flexible. Individual

vacuum receivers can be assigned to any one of the eight

loading systems. Each receiver can be configured for one of

the following:

l Single-material loading.

l Ratio loading, with or without automatic material layering.

l Positive (air-operated) receiver discharge.

l Material line purging.

l Loader fill alarm to work with an optional fill sensor

mounted in the receiver body or direct feed chamber.

l Hopper fill alarm to work with an optional demand sensor

mounted in a drying hopper or other material vessel.

l No alarm.

The controller and control automatically turn on when power

is applied to the I/O station. After a bootup sequence the home

screen displays. From the home screen the operator can scroll

to all monitoring and control functions.

Loading...

Loading...