Page 57

MOTOR RUNS IN WRONG DIRECTION:

A. The Al and A2 output leads to the motor are incorrectly

wired - exchange these leads.

B. On shunt wound motors only the shunt field Fl and F2 leads are incorrectly wired

– exchange these leads.

MOTOR DOES NOT MAINTAIN SPEED UNDER LOAD:

A. IRCOMP potentiometer is set too low - adjust clockwise

B. Motor is overloaded - correct overload condition.

C. Incorrect jumper programming – check jumpers.

D. Defective component on main PC board – replace (See Critical Components)

E. Motor brushes worn - replace as specified in motor instruction manual.

MOTOR DOES NOT COME TO FULL STOP:

A. Minimum Speed potentiometer (MIN) is set too high -readjust

B. Defective speed or torque potentiometer, component on regulator PC

board, Start/Stop switch, or rectifier cube -replace as required.

(See Critical Components)

NO SPEED CONTROL:

F. Defective rectifier cube - replace as required (See Critical Components)

G. Defective component on main PC board - replace as required.

(See Critical Components )

H. Incorrectly wired or defective speed potentiometer - check the wiring.

I. Incorrect jumper programming - check jumper programming.

J. If the control (after rechecking all the wiring for proper and secure connections) is

still inoperative, make the following voltage checks. Double check to make sure

that armature leads Al and A2 are not grounded.

K. High resistance ground on motor armature

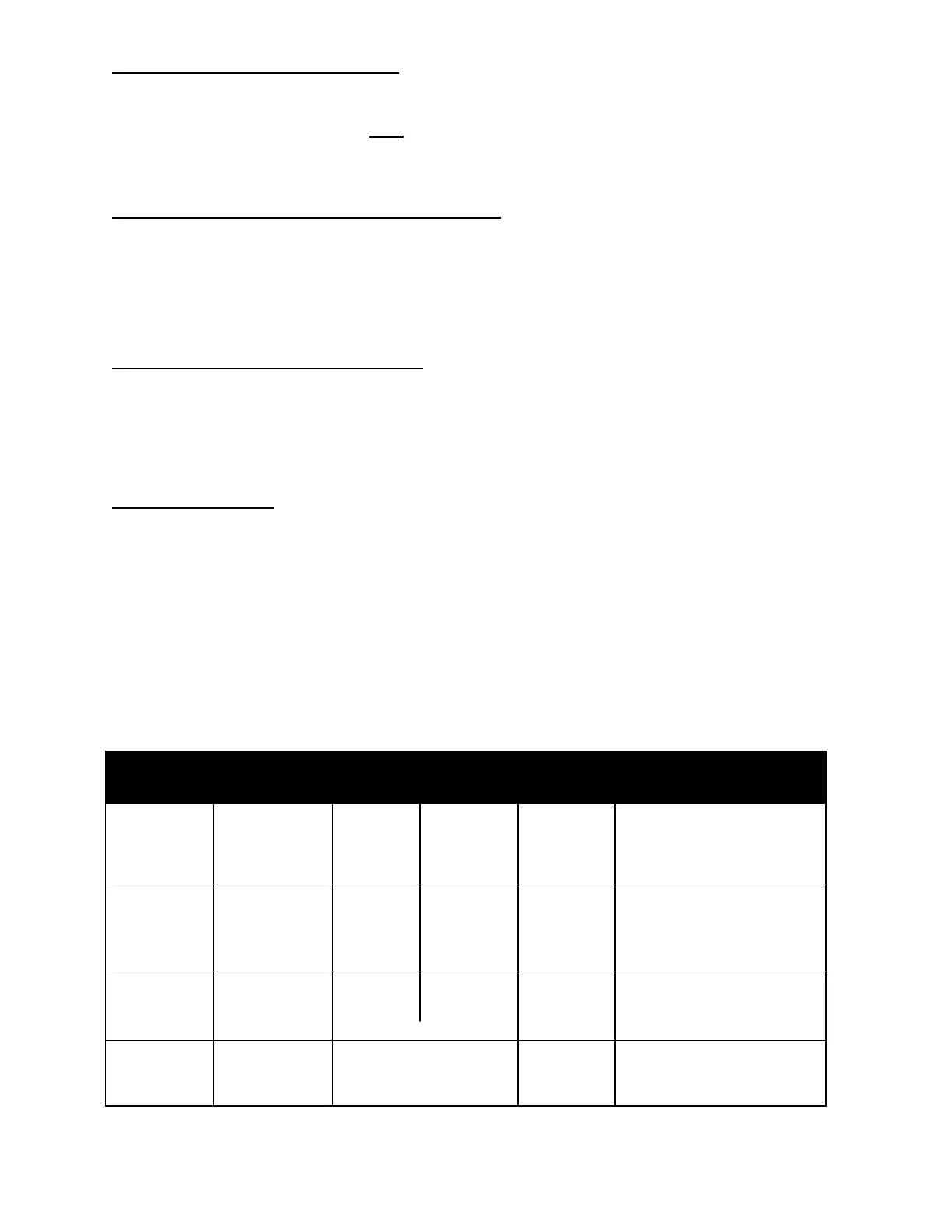

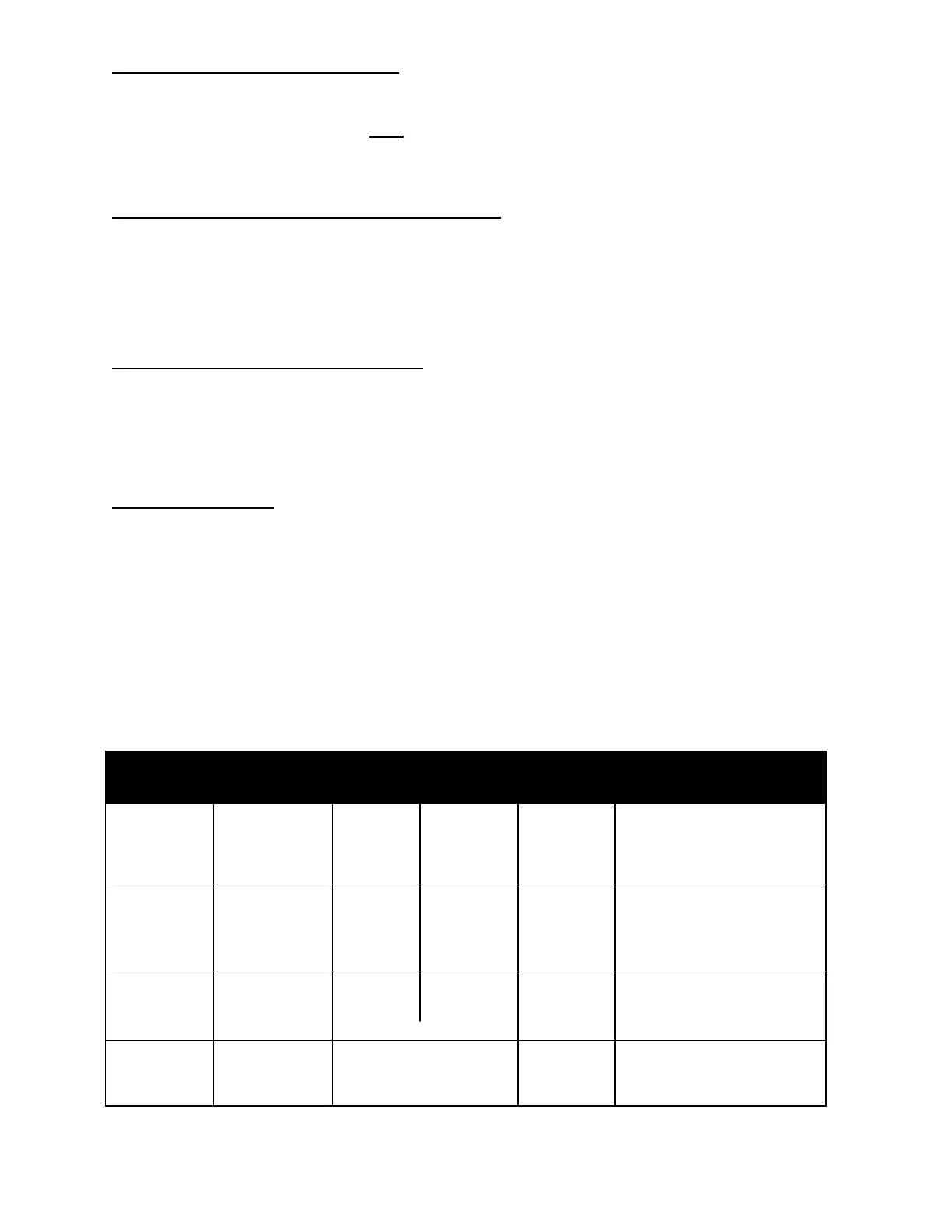

VOLTAGE CHECK CHART

Step Function

Normal

Voltage

Readings

Terminal

or Point

Probable Cause

1

with AC

Power “on”

Voltage to

Rectifiers

120 Vac 240 Vac

±10% ± 10%

ACl

AC2

On

power

cube

Blown Fuses

2*

Speed

command

0 to +10 0 to +10

Vdc Vdc

10-12

Defective speed

adjustment

potentiometer or

circuit board assembly

3 Field Supply

Voltage

100 Vdc 200 Vdc

+Fl

-F2

Defective field diodes

defective encapsulated

bridge rectifier

assembly

4* Armature

Voltage

0-90 Vdc 0-1 80 Vdc

+Al

-A2

Defective encapsulated

bridge rectifier ass’y, or

circuit board assembly

*Depends on the setting of the speed adjustment knob

Loading...

Loading...