Coolerado Installation

Page 16 of 63

3.) Slope the line from the unit to the drain valve for

proper draining and freeze protection.

4.) To drain the line and water distribution system it

must be turned on for a few minutes to allow the

water to drain and air to pulled into the system. This

is done by turning the thermostat to require a cool

call.

WATER DISTRIBUTION SYSTEM

The water distribution system, (located inside the unit) is a

combination pressure regulator, 24 VAC solenoid valve and

water distributions manifold. The valve is designed to

deliverer the correct water flow to each of the systems heat

exchangers.

NOTE: Water Distribution System pressure should be

adjusted in the field to 5.5 psi, (38 kPa). The adjustment

must be made in the field to adjust for elevation above sea

level.

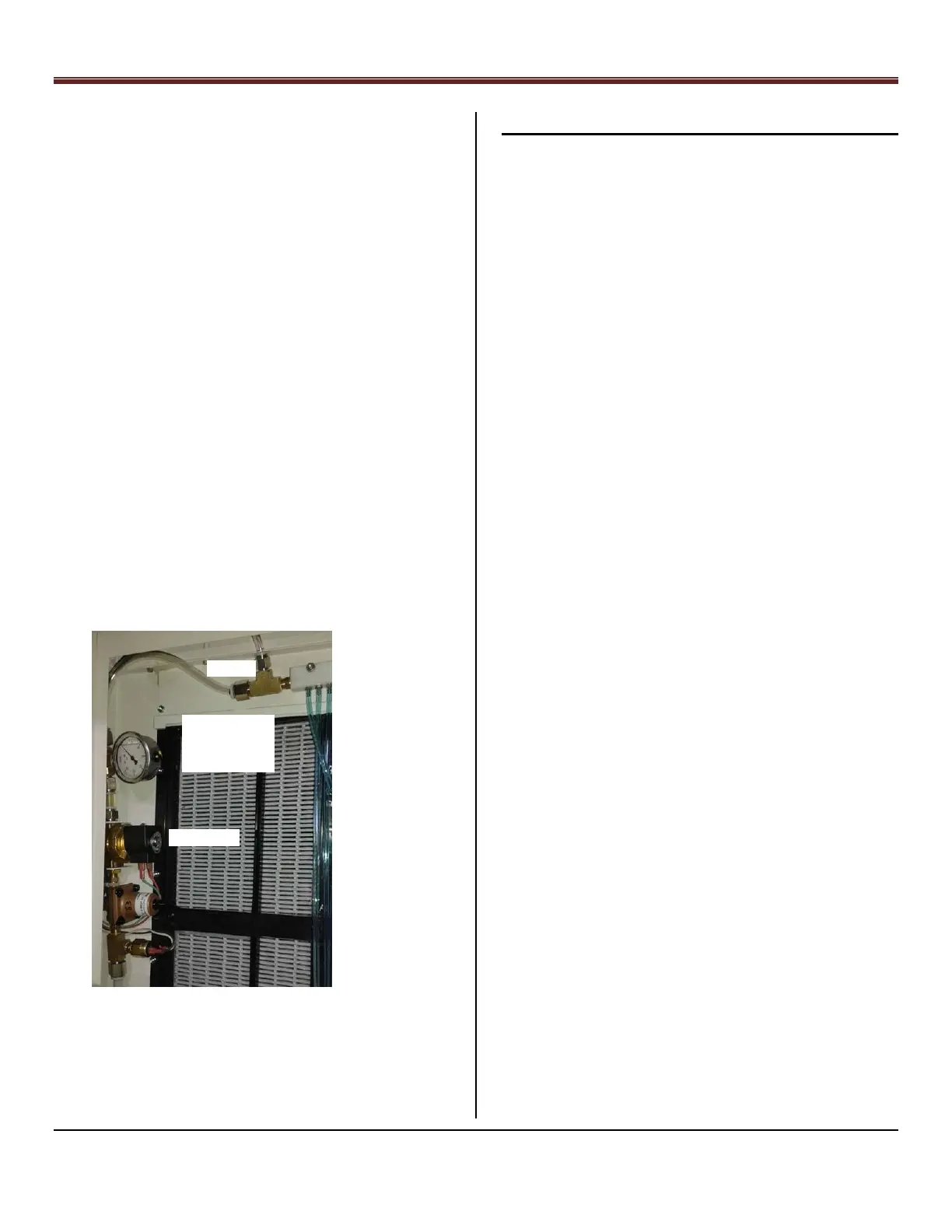

CAUTION: It is absolutely essential that the pressure

regulator be set to deliver the proper pressure at the water

distribution head before installation can be considered

complete. For the most accurate setting possible, take a

dynamic pressure reading at the point where the water

supply enters the water distribution head. This can be done

by temporarily installing a pressure gage immediately at the

point where the water supply enters the water distribution

header, as in the following picture, and adjusting the

dynamic pressure to the desired level.

Water Header Pressure Location, Figure 27.

Step 10 –Electrical Power Connections

Note: Do not power on the unit until Step 15.

See Appendix 2 for Details.

See Appendix 4 for multi-unit wiring.

DANGER: To avoid personal injury or death, do not supply

power to unit with the units’ high voltage terminal box

cover removed.

WARNING: NOT SUITABLE FOR USE WITH SOLID-STATE

SPEED CONTROLS

CAUTION: Be sure field wiring complies with all local and

national fire, safety, and electrical codes, and voltage to

system is within limits shown on unit rating plate. Contact

local power company for correction of improper voltage.

See unit rating plate for recommended circuit protection

device.

NOTE: Keep wiring color coded according to system

drawings for easy troubleshooting and standardization. For

color code reference, see Appendix 2.

NOTE: Operation of the unit on improper line voltage

constitutes abuse and could affect unit reliability. See the

unit rating plate. Do not install unit in system where voltage

may fluctuate outside of normal voltage fluctuations

NOTE: Use copper conductors only between the disconnect

switch and the unit.

ROUTE GROUND AND POWER WIRES

DANGER: The unit cabinet must have an uninterrupted or

unbroken ground to minimize personal injury if an electrical

fault should occur. The ground may consist of electrical wire

or metal conduit when installed in accordance with existing

electrical codes. Failure to follow this warning can result in

an electric shock, fire, or death.

CAUTION: Without an uninterrupted or unbroken ground

the motor can have arcing across the bearings causing

premature failure of fan motor.

Remove access panel and electrical box cover to gain access

to unit wiring. Extend wires from disconnect through power

wiring hole provided and into unit control box. Size wires per

National Electric Code.

CONNECT GROUND AND POWER WIRES

Single Phase Motors: The unit fan motors will run on 200 to

277 VAC, 50/60 Hz single phase with an electrical circuit

breaker of 5 amperes. The transformers provided are 208

VAC or 240 VAC to 24 VAC only. In some instances, a 277 VAC

Measure Header

Pressure Between

Solenoid Valve and

Soap Tee Using ½”

OD Tube Connectors

Solenoid Valve

Soap Tee

Loading...

Loading...