© 2010, IMI Cornelius Inc.

- 26 -

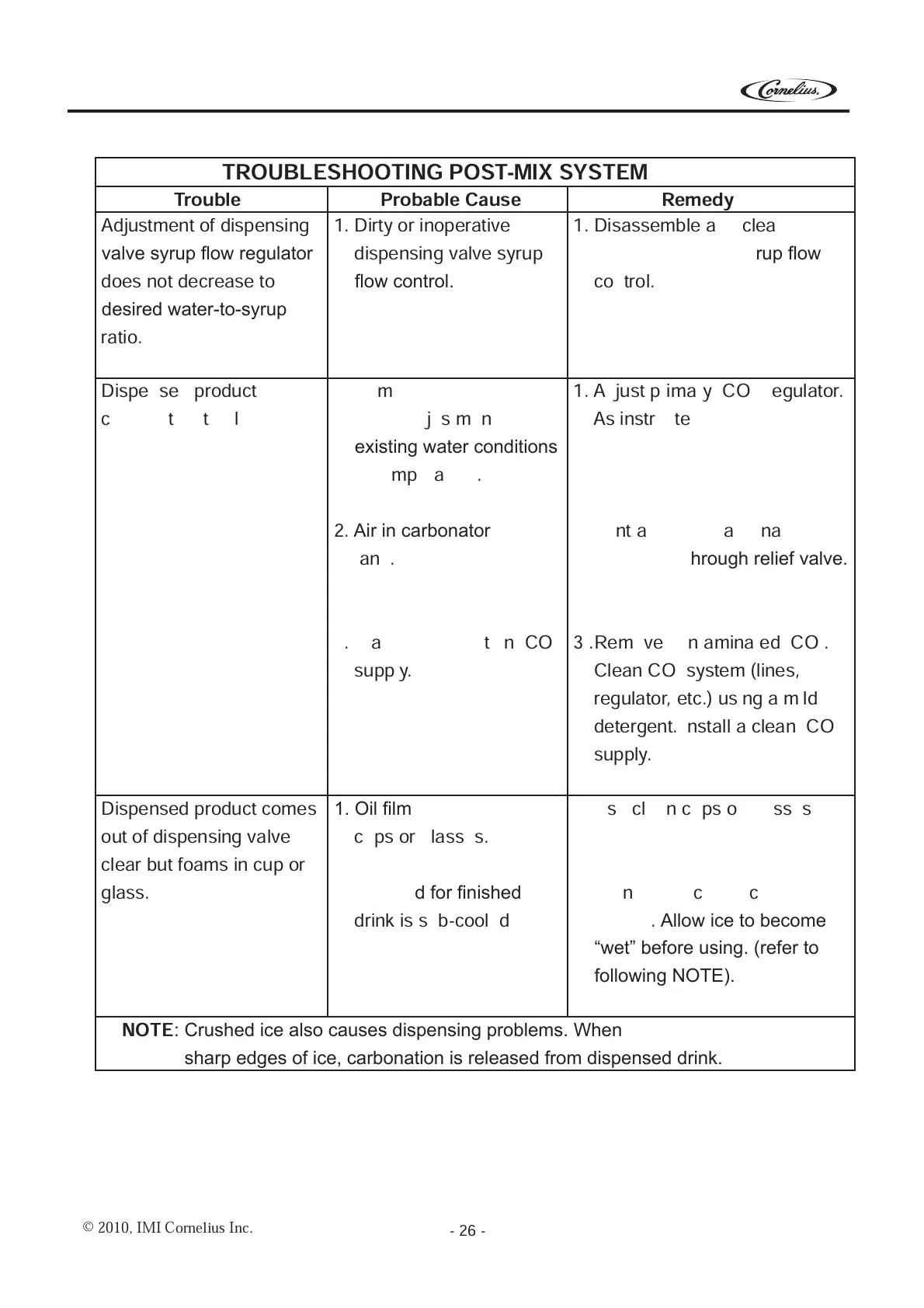

TROUBLESHOOTING POST-MIX SYSTEM

Trouble Probable Cause Remedy

Adjustment of dispensing

valve syrup !ow regulator

does not decrease to

desired water-to-syrup

ratio.

1. Dirty or inoperative

dispensing valve syrup

!ow control.

1. Disassemble and clean

dispensing valve syrup !ow

control.

Dispensed product

carbonation too lo

w

.

1. Primary CO2 regulator

out of adjustment for

existing water conditions

or temperature.

2.

Air in carbonator water

tank.

3. Water, oil, or dirt, in CO2

supply.

1. Adjust primary CO2 regulator.

As instructed.

2. Vent air out of carbonator

water tank through relief valve.

3 .Remove contaminated CO2.

Clean CO2 system (lines,

regulator, etc.) using a mild

detergent. install a clean CO2

supply.

Dispensed product comes

out of dispensing valve

clear but foams in cup or

glass.

1. Oil "lm or soap scum in

cups or glasses.

2. Ice used for "nished

drink is sub-cooled.

1. Use clean cups or glasses.

2. Do not use ice directly from

freezer.

Allow ice to become

“wet” before using. (refer to

following NOTE).

NOTE

: Crushed ice also causes dispensing problems. When "nished drink hits

sharp edges of ice, carbonation is released from dispensed drink.

Loading...

Loading...