22

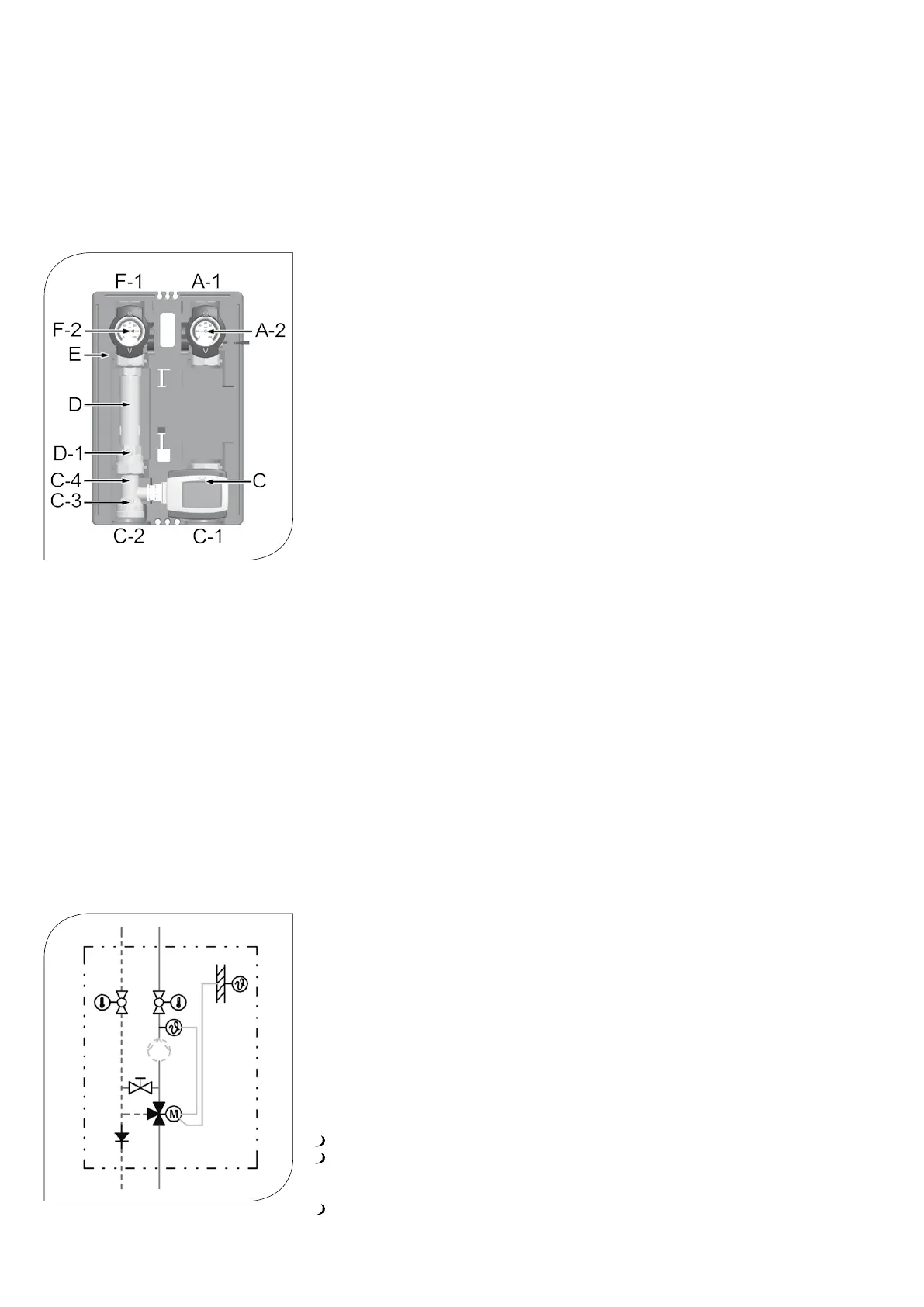

A-1 Flow to the consumer circuit

A-2 Full metal thermometer with immersion sleeve, integrated in the ball valve (flow)

C Weather-compensated actuator

C-1 Flow from the heat generator

C-2 Return to the heat generator

C-3 Non-return valve, can be opened (4.9 mbars)

C-4 3-way mixing valve with adjustable bypass

D Return pipe

D-1 Check valve, can be opened (19.6 mbars)

E Design insulation with optimised function

F-2 Full metal thermometer with immersion sleeve, integrated in the ball valve (return)

F-1 Return from the consumer circuit

2.3 EQUIPMENT

2.4 FUNCTION

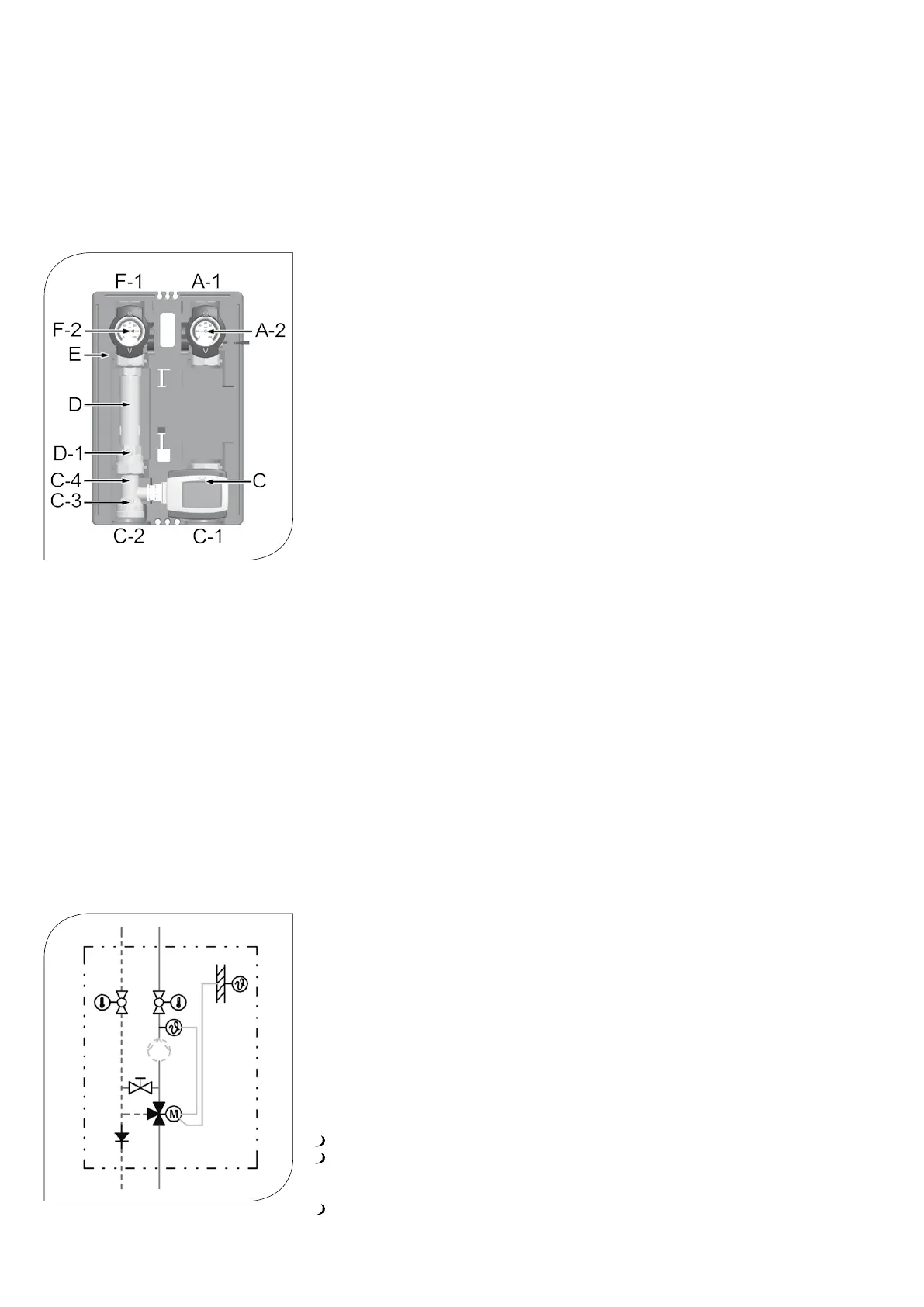

3-way mixing valve with adjustable bypass

The flow temperature of the pump group is controlled via the integrated mixing valve.

Hot water from the boiler and cold return water are mixed to obtain the desired flow

temperature of the pump group. The mixing valve is adjusted via the weather-compensated

actuator. Due to the premixing rate that must be adjusted at the bypass of the mixing valve,

a certain amount (0-30%) of cold return water is added to the flow water. The 3-way actuator

can thus work over the whole adjustment range (0-100%), although only a small amount of

water from

the boiler is necessary.

Example: Panel heating systems operate on a low temperature level with small temperature

differences but with high flow rates. It is therefore sufficient to "inject" a small amount of hot

water into the "warm" return water.

Application range of the use of the bypass:

Consumer circuits with considerably lower flow temperature than the boiler flow temperature

Control of radiant floor heating and panel heating systems

Application range of the use without the bypass:

Radiator circuits and air heater circuits

Loading...

Loading...