16

ADJUSTMENTS

Blade Alignment

Your CX205/CX206 table saw is shipped

from the factory fully aligned so that the

mitre slots are parallel to the saw blade.

However, shipping and rough handling may

have affected this. It should be checked

and adjusted if needed.

To check the alignment, clamp a dowel to

the front of the miter gauge and raise the

saw blade and pick out a saw tooth on the

front of the blade and set the dowel in front

of the miter gauge so that the dowel end

just touches the edge of the saw tooth.

Mark the tooth with a felt marker and rotate

the saw blade by hand to bring the marked

tooth to the rear of the saw. Now, gauge

this tooth with the dowel. If the tooth is in

the same position, the blade is parallel to

the miter slot.

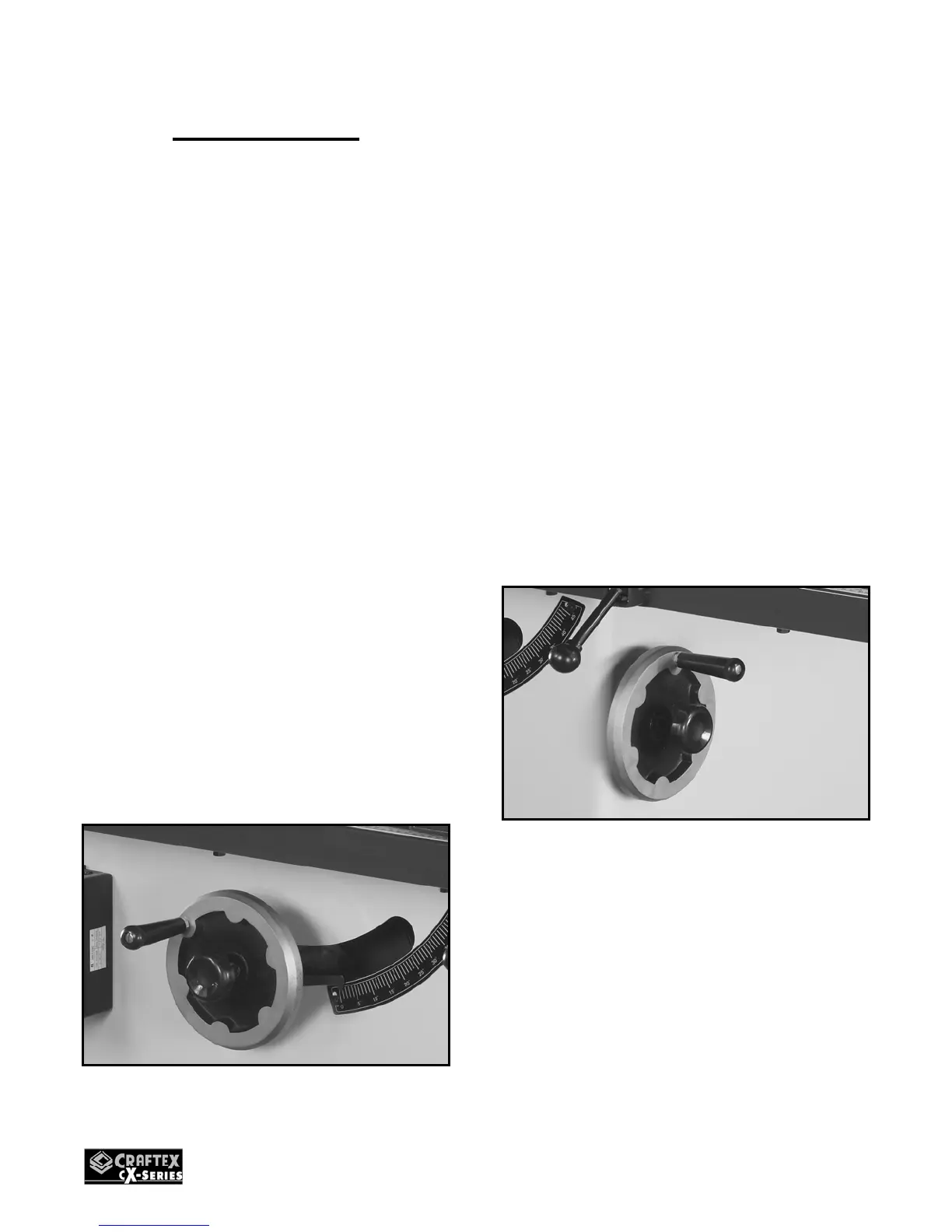

Blade Height Adjustment

The hand wheel on the front face of the saw

cabinet is to control the blade height.

To adjust the blade height, loosen the knob

and turn the hand wheel to set the blade at

the desired height. Rotate the knob clock-

wise and tighten it back.

Figure-16 Blade height hand wheel

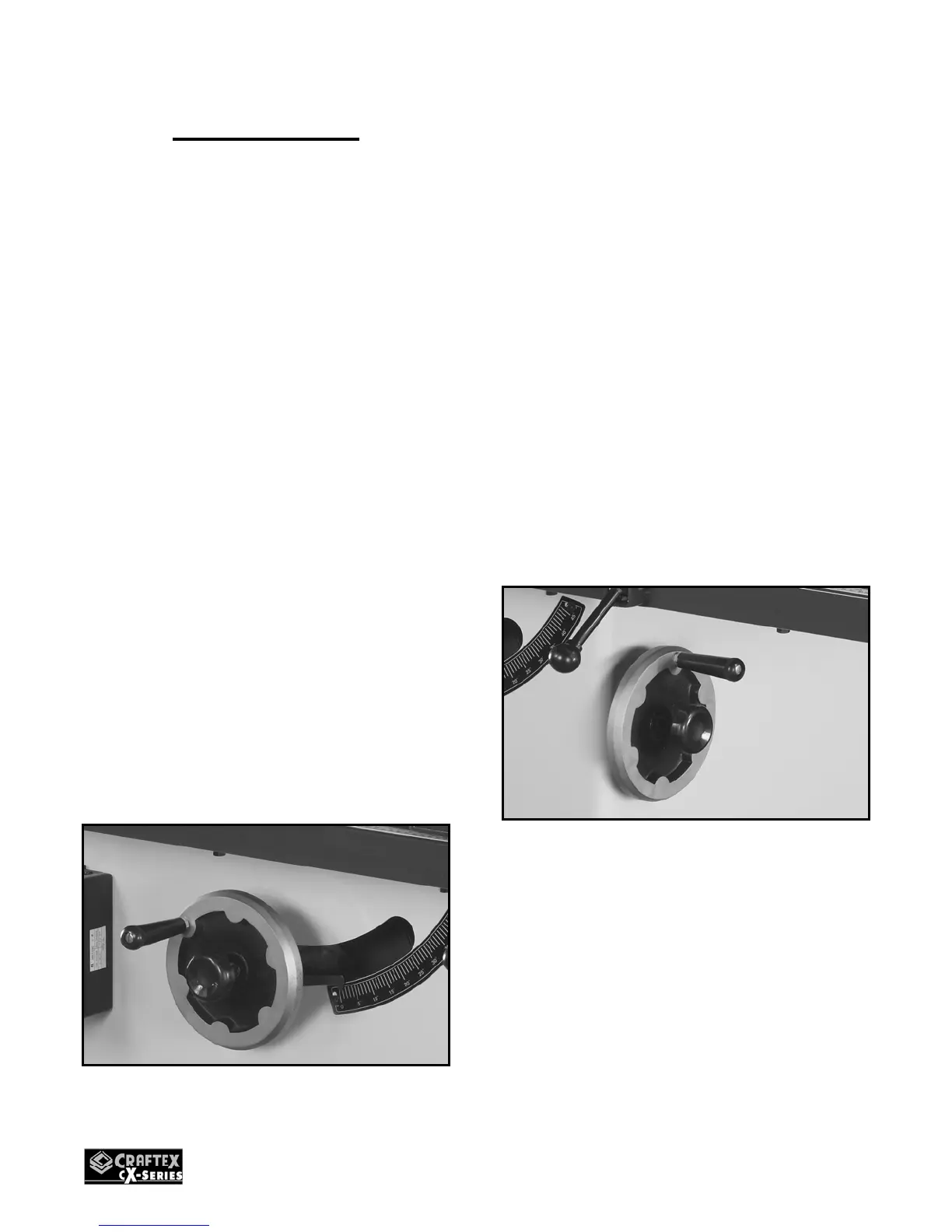

Blade Tilt Adjustment

The blade can be tilted at any angle

between 90-degree and 45-degree and the

blade tilt is controlled by the hand wheel on

the side of the saw cabinet. There are

positive stops at both 45 and 90 degrees.

The tilt angle dial at the front face of the

cabinet shows the angle the saw blade is

sitting at.

To adjust the blade tilt, loosen the hand

wheel lock knob and rotate the hand wheel

until the blade is at the desired angle. Keep

an eye on the tilt angle dial and once the

blade is at the desired angle, lock the hand

wheel by rotating the lock knob.

Make sure not to over tighten the lock knob.

Figure-17 Blade tilt hand wheel

Fence Adjustment

The fence should be flush with the table

surface. To raise or lower the fence, use

the nylon screws.

The edge surfaces of the fence must be

perpendicular to the table surface. Use a

combination square for verification and

adjust the nylon square as required.

Loading...

Loading...