9

Curtis 1230 Manual, Rev. C

2 — INSTALLATION & WIRING: Controller

☞

C A U T I O N

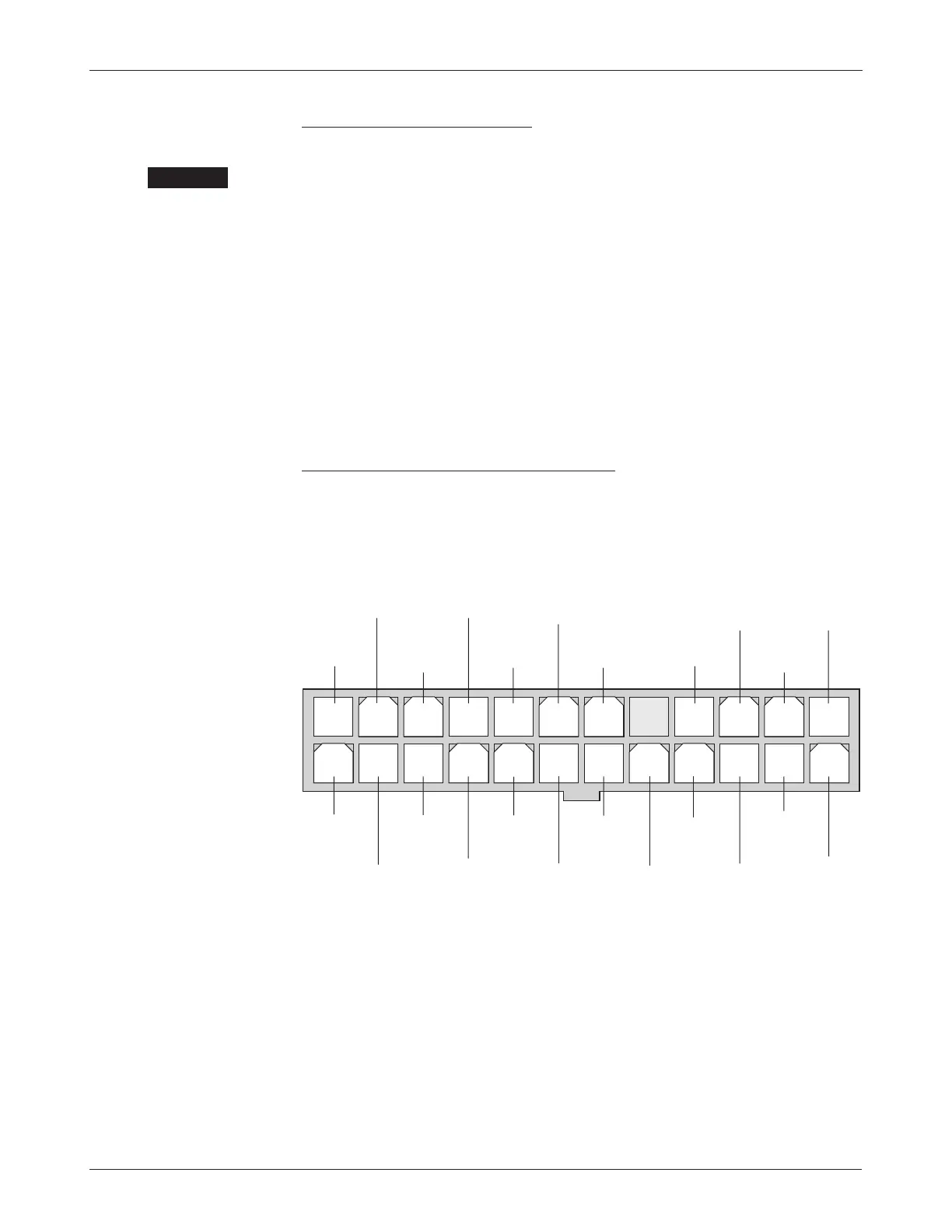

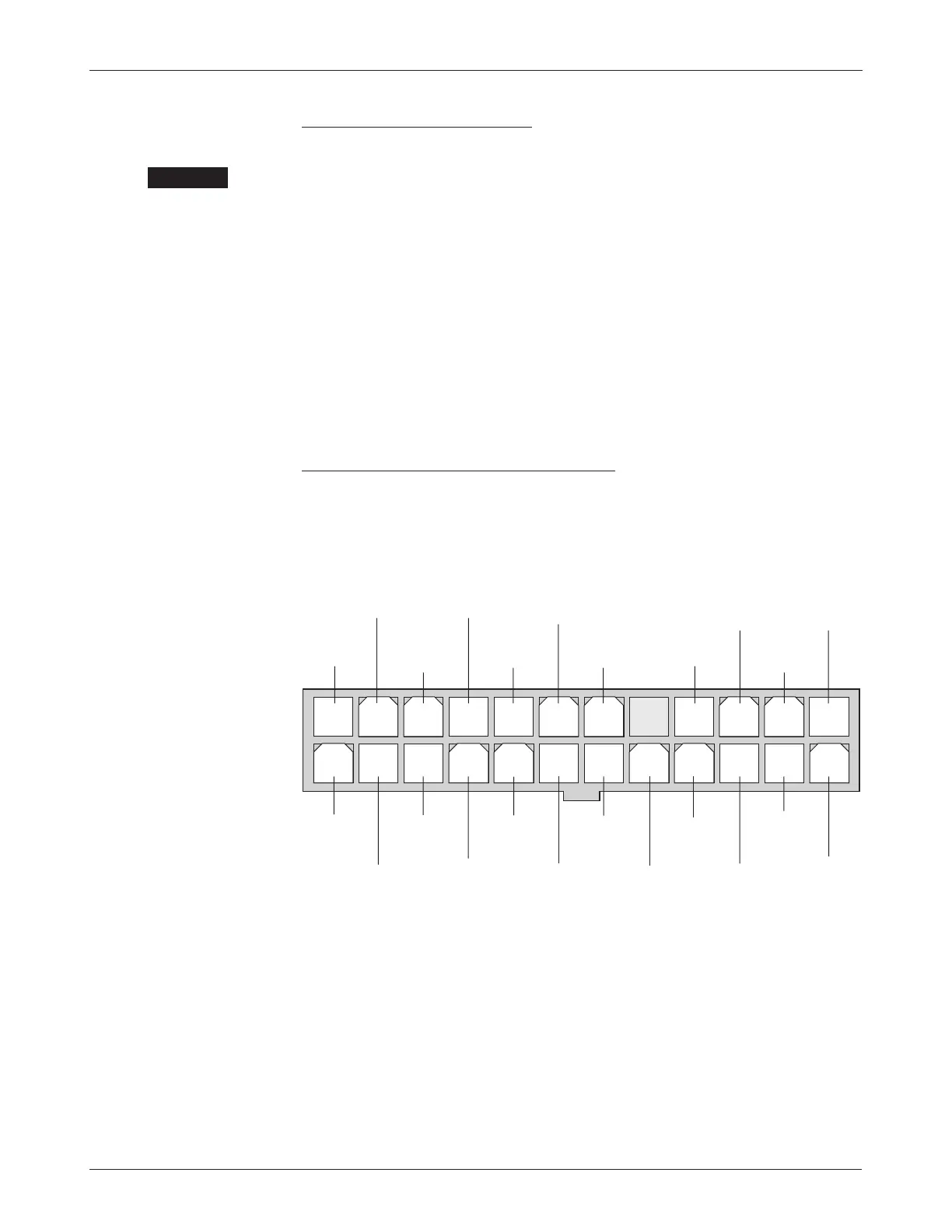

13 14 15 16 17 18 19 20 21 22 23 24

1 2 3 4 5 6 7 8 9 10 11 12

LIFT

RELA

Y

(feed-thru)

DISPLAY

SUPPLY

DISPLAY

GROUND

FORWARD

SWITCH

24-pin detail (see Fig. 3):

BATTERY

LED

POT

LOW

SPEED

LIMIT

PO

T

INHIBIT

LOWERING

VALV

E

(feed-thru)

EMERGENCY

REVERSE

EMERGENCY

REVERSE

CHECK

POT

HIGH

AU

X

GROUND

DISPLAY

DATA

REVERSE

SWITCH

LOWER

SWITCH

(feed-thru)

INTERLOCK

MODE

SWITCH

(M1/M2)

KEYSWITCH

INPUT (KSI)

THROTTLE

WIPER

MAIN

CONTACTO

R

LIFT

SWITCH

(feed-thru)

STATUS

LED

Power Wiring, Configuration A

Motor phase wiring is straightforward, with the motor’s U, V, W phases con-

nected directly to the controller’s

U, V, W studs. CAUTION: The sequence of the

motor phase connections will affect the operation of the emergency reverse

feature. The forward and reverse switches and the

U, V, W connections must

be configured so that the vehicle drives away from the operator when the

emergency reverse button is pressed.

The negative battery terminal is always connected directly to the B- stud.

The positive battery terminal is typically connected to the

F+ stud via the ex-

ternal main contactor, as shown in Figure 3. If the main fuse in not mounted

on the controller,

F+ is not used and the positive battery terminal is connected

to the

B+ stud.

If a main contactor is not required, the positive battery terminal can be

connected directly to the

B+ or F+ stud on the controller.

Standard Control Wiring, Configuration A

Wiring for the input switches and contactors is shown in Figure 3; the 24-pin

connector is shown in more detail below.

The main contactor coil must be wired directly to the controller as shown in

Figure 3. The controller can be programmed to check for welded or missing

contactor faults and uses the main contactor coil driver output to remove power

from the controller and motors in the event of various other faults. If the main

contactor coil is not wired to J1 Pin 22, the controller will not be able to

open the main contactor in serious fault conditions and the controller will

not be protected against reverse battery polarity.

Feed-throughs from J1 Pin 11 to Pin 23 and from J1 Pin 12 to Pin 24

are provided as a convenience, to simplify the wiring harness for lift/lower.

Loading...

Loading...