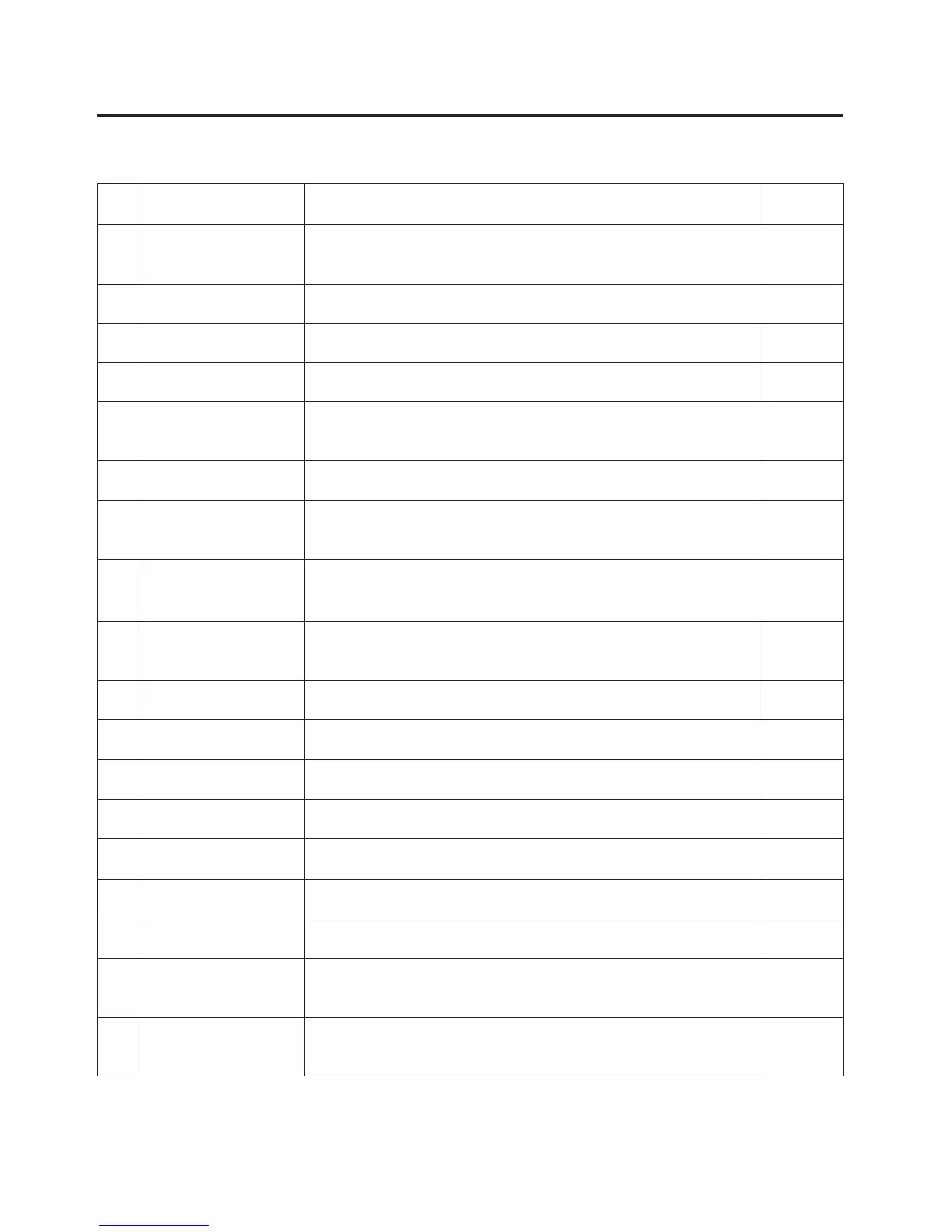

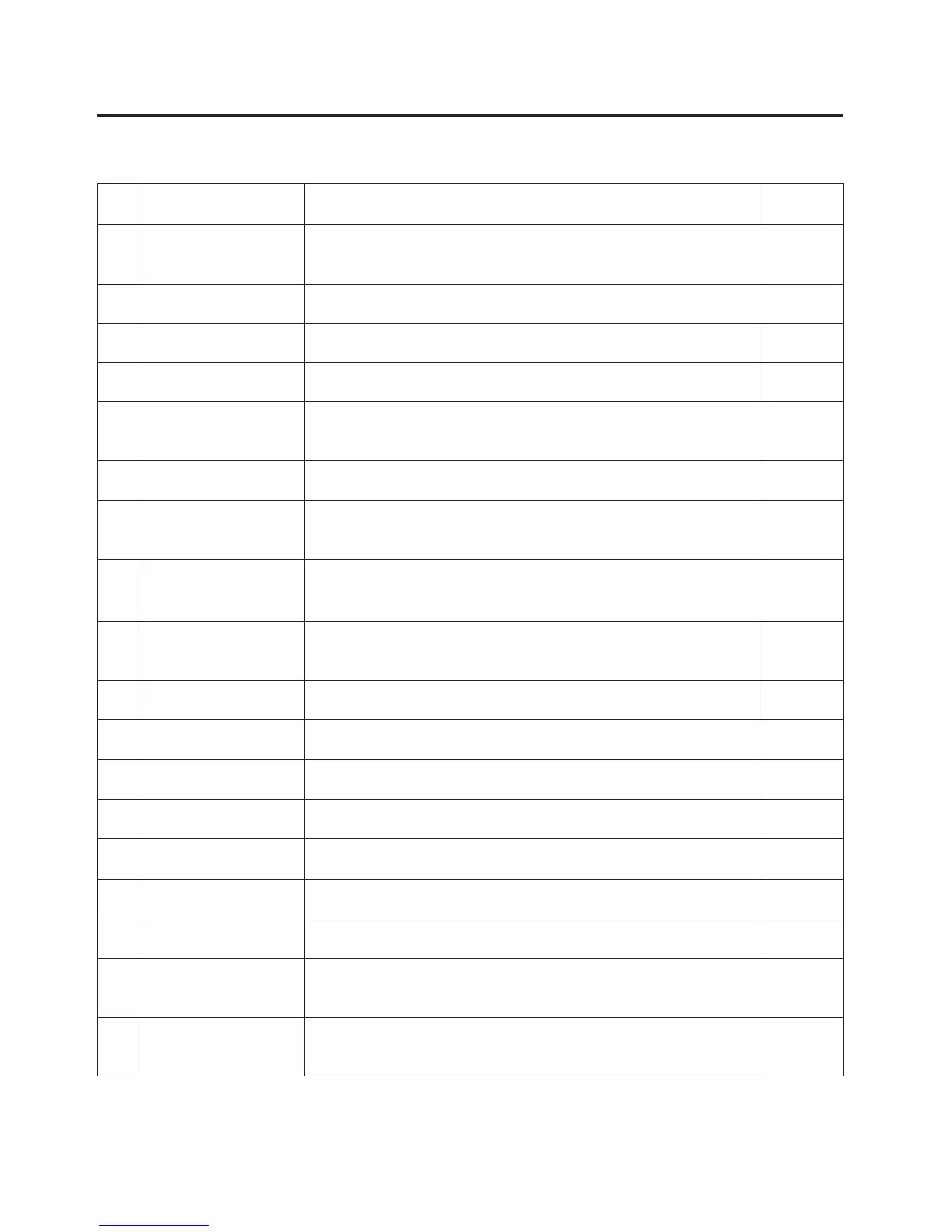

1–14 GENERAL INFORMATION

10. BODY REPAIR PROCEDURES

Procedure Remarks

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

Inspect the damaged parts and the extent of damage and make

plans for the repair.

Prepare the new parts, special repair tools and others.

Remove the related parts for repair.

Roughly pull out and straighten the damaged areas.

Cut off the damaged areas and drills on the spot weld nuggets

and pry off the remaining spot weld flanges.

Peel off the undercoat and sealer.

Mold damaged areas and even out the welding flanges and fill

any holes.

Grind both sides of the welding section and set the new parts and

tack welds for temporary installation.

Inspect the dimensions for correct position and preinstall the exte-

rior parts and check the clearances and level differences.

Perform a trial welding and the main welding.

Finish the welding areas and even out the flanges for a close fit.

Apply the sealer to the matching and over lapped surface.

Apply the undercoat to the required areas.

Apply the paint.

Apply the deadner to the designated areas.

Coating the anti-rust agents to the designated areas.

Install the related parts and rub in grease to the moving parts and

replenish the cooling liquid, oil, aircon gas and others.

Check all operations, wheel alignments, leaks, head lamp aim and

others with the specified check sheet.

No. Operation

Inspection

Preparation

Removal

Pull out

Cut and pry off

Peel off

Molding

Set the new parts

Inspection

Welding

Finish

Sealing

Undercoating

Painting

Deadner

Anti-rust agents

Installation

Check and adjust

Loading...

Loading...