WELDING AND TOOLS 3–3

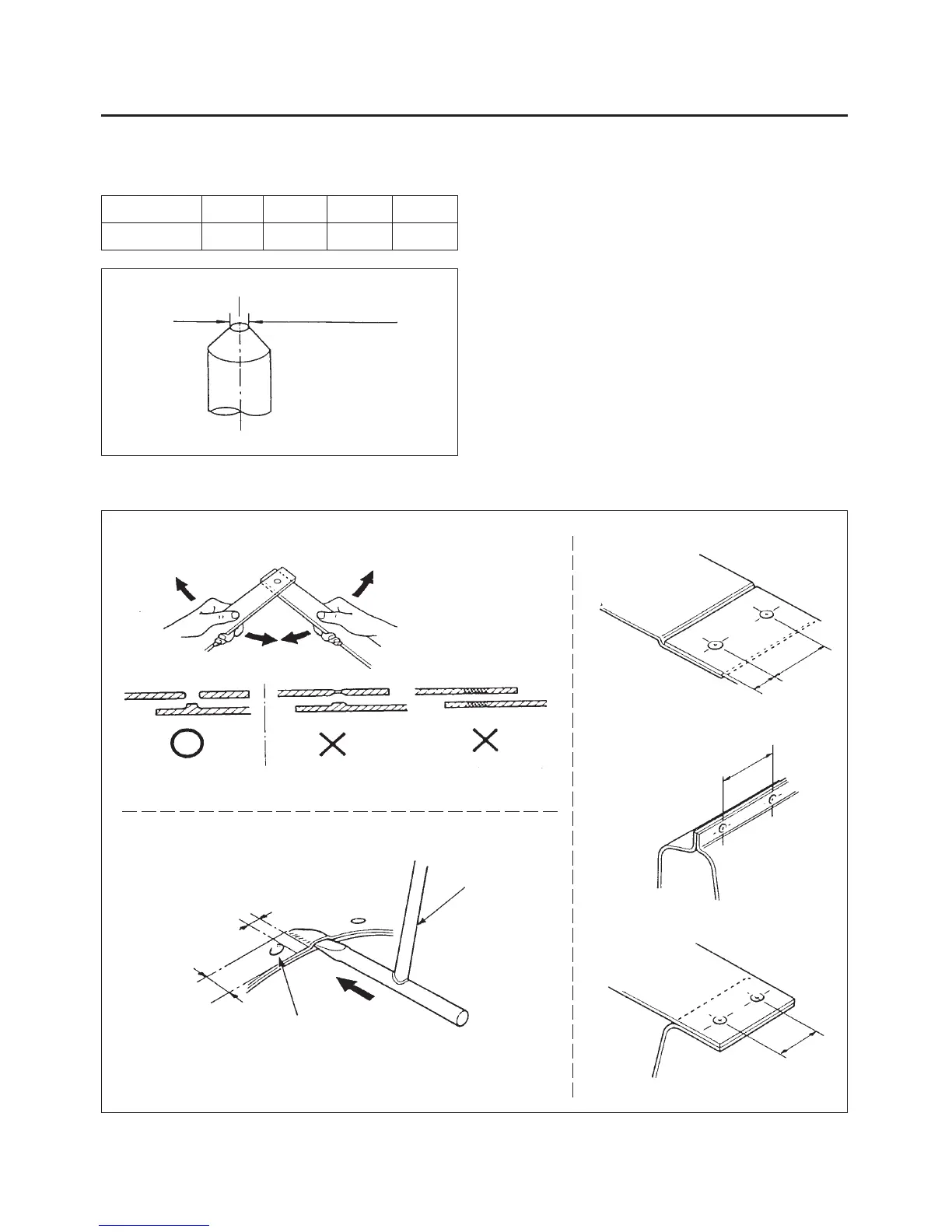

1-3. WELDING STRENGTH TEST

Even if you perform the welding in accordance with the

conditions, the strength of the welded sections may fluc-

tuate widely with drops in the voltage and other factors.

The quality of the welding cannot be evaluated unless

the welded sections are destroyed.

Provide yourself with a steel plate of the same thick-

ness and conduct a destruction test.

• If holes appear in the steel plates, this means that

the welding is standard strength.

• Drive a wedge between two panels near the nug-

get. If the welded parts do not come apart and the

diameter of the nugget appears more than 3 mm,

the welding should be satisfactory.

Fig. 4

Stop inserting the wedge when

the full size of the nugget appears.

WEDGE

Plate thickness

0.6 0.9 1.2 1.6

Tip diamter ø4.5 ø5.0 ø5.5 ø6.0

Fig. 3

Tip diameter

(Unit : mm)

• Plate thickness and tip diameter

6~9mm/

30mm

Loading...

Loading...