ROOF, BACK PANEL AND REAR FLOOR PANEL 5–3

1-2. REPAIR PROCEDURE

1. Remove the related parts.

• Room lamp, door weatherstrip and pillar trims.

• Headlining and wiring harness.

• Wiper, cowl and windshield.

• Rear glass and others.

2. Pull out and straighten the damaged area to approxi-

mately the original shape.

NOTE: Use heat-resistant protective cover for pro-

tect painting areas, seats, carpets and other parts.

• Attach the car to the frame straightener by tight-

ening the underbody clamps at the horizontal

pinch welds.

• Before cutting off the roof panel, pull them out so

that they are restored to the original shape.

• Do not pull out more than necessary.

• Pull out and straighten the related damaged parts

to approximately their original shape.

NOTE: Make sure that the right and left pillars are

parallel with the windshield surface. Check the door

for proper opening and closing.

3. Keep the body, level.

• Jack up the body, and place safety stands at the

four designated places of the frame door open-

ing.

4. Cut off the shaded areas of the roof panel.

• Cut the roof weld flanges with a hand saw and

snips at the roof panel and roof frames.

• Using a chisel, pry off the roof panel along the bold

lines as shown.

• Center punch around the spot weld imprints of the

roof welded flange.

• Drill holes using the spot cutter.

• Using a chisel and a disc sander, pry off the

welded flange from the front, rear body pillar and

roof panel.

• Level and finish the burrs of welded flanges with

a disc sander.

CAUTION: To prevent eye injury, wear goggles or

safety glasses whenever sanding, cutting, or grind-

ing.

5. Peel off the sealer.

• Peel off the sealer with a steel spatula at the weld-

ing areas of the frame door opening.

6. Mold damaged related parts.

• Use a hammer and dolly to mold damaged areas

of the front, rear body pillar inner and frame door

opening.

• Even out the welding flanges with a hammer and

dolly for close fit with the roof panel welding

flange.

• Fill any holes drilled by welding.

7. Set the new panels.

• Grind both sides of the welding section of the rail

windshield header, support roof panel, frame rear

roof panel and roof panel with a disc sander to

remove the paint and expose the steel plate.

CAUTION: To prevent eye injury, wear goggles or

safety glasses whenever sanding, cutting, or grind-

ing.

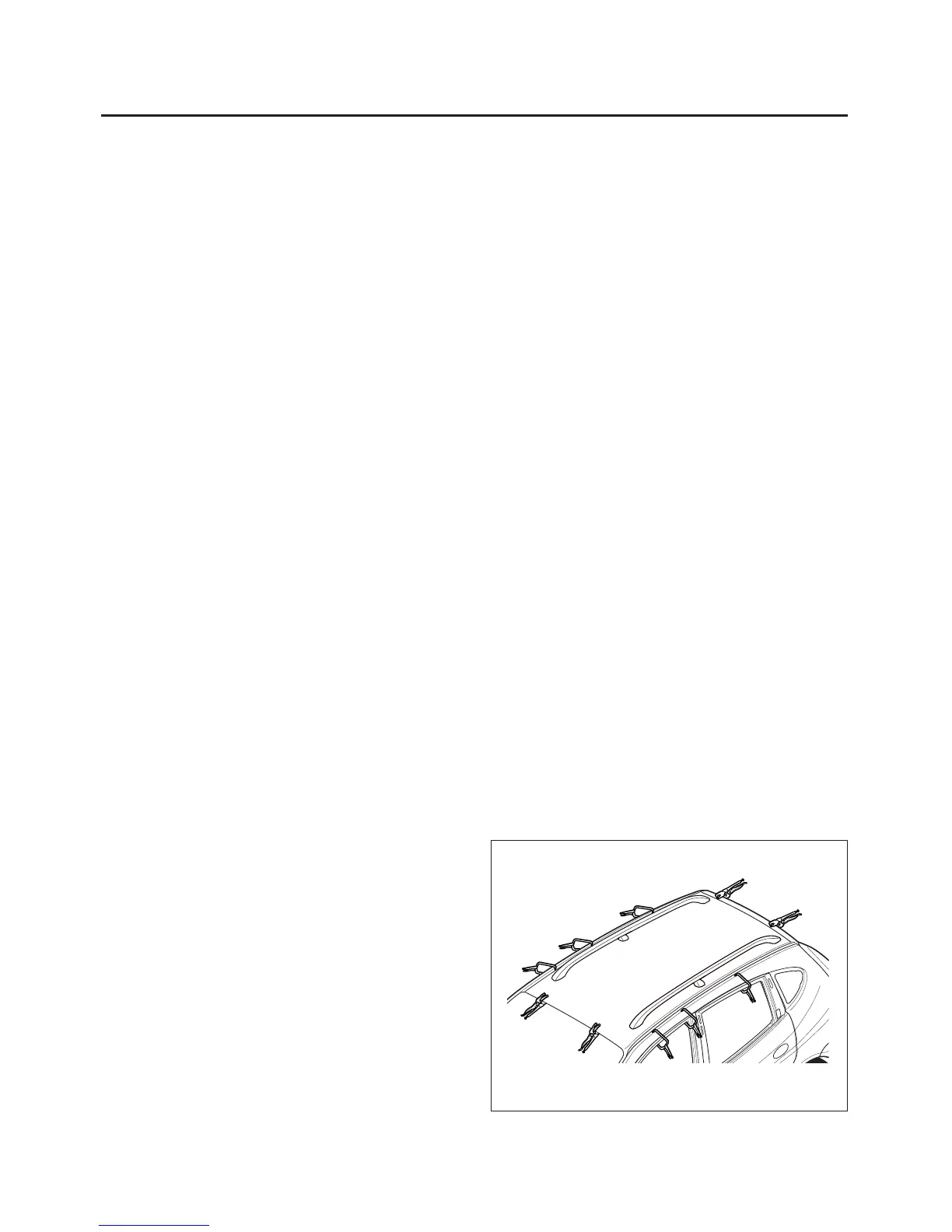

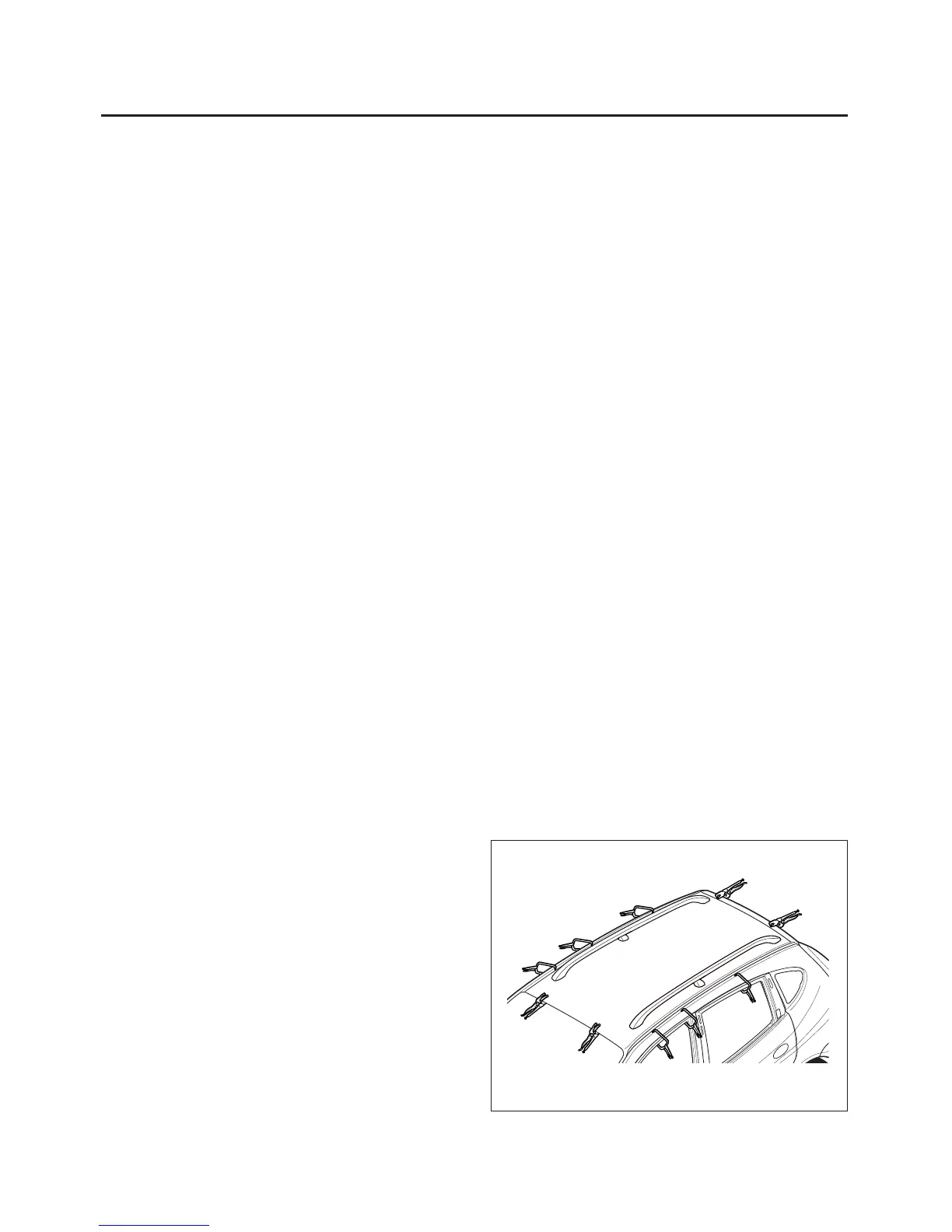

• Temporarily set the new three frames and roof

panel and clamp with the vise grips.

NOTE: Check that the flange surface fit closely. Be

careful not to twist or deform the roof panel.

Fig. 2

Loading...

Loading...