www.DaikinApplied.com 13 CAT 258 • REBEL APPLIED ROOFTOP

Extensive selection exibility from 200 to 1,125 MBh intput can

satisfy wide ranging needs. Staged control, low modulating (5-

10:1), high modulating (10-20:1) and 100:1 modulating control

with SCR Preheat provides the exibility to solve diverse needs

• Gas furnace assemblies are ETL or ETL-Canada listed

• All burner assemblies are factory tested and adjusted

prior to shipment

• Air temperature rise capability of up to 100°F on most

models

• 439 stainless steel heat exchangers provide long life in

100% outside air applications

• Fuel connections are pre-piped to the exterior for

simplied install with no internal unit eld connections

required

• Heating control fully integrated into the unit’s MicroTech 4

control system

®

• Full turndown with continuous modulation between 1%

and 100% of rated capacity provides precise temperature

control for a comfortable tenant environment, even during

shoulder seasons and in demanding applications such

as, 100% make-up air and VAV systems

• Solves the mixed air tempering requirements of VAV

systems when meeting ASHRAE 62.1 ventilation

requirements at cold ambient, light load conditions

• Operates at normal inlet gas pressures, throughout the

entire modulation range

• 5 burner sizes ranging from 200 MBh to 1,125 MBh input

capacity

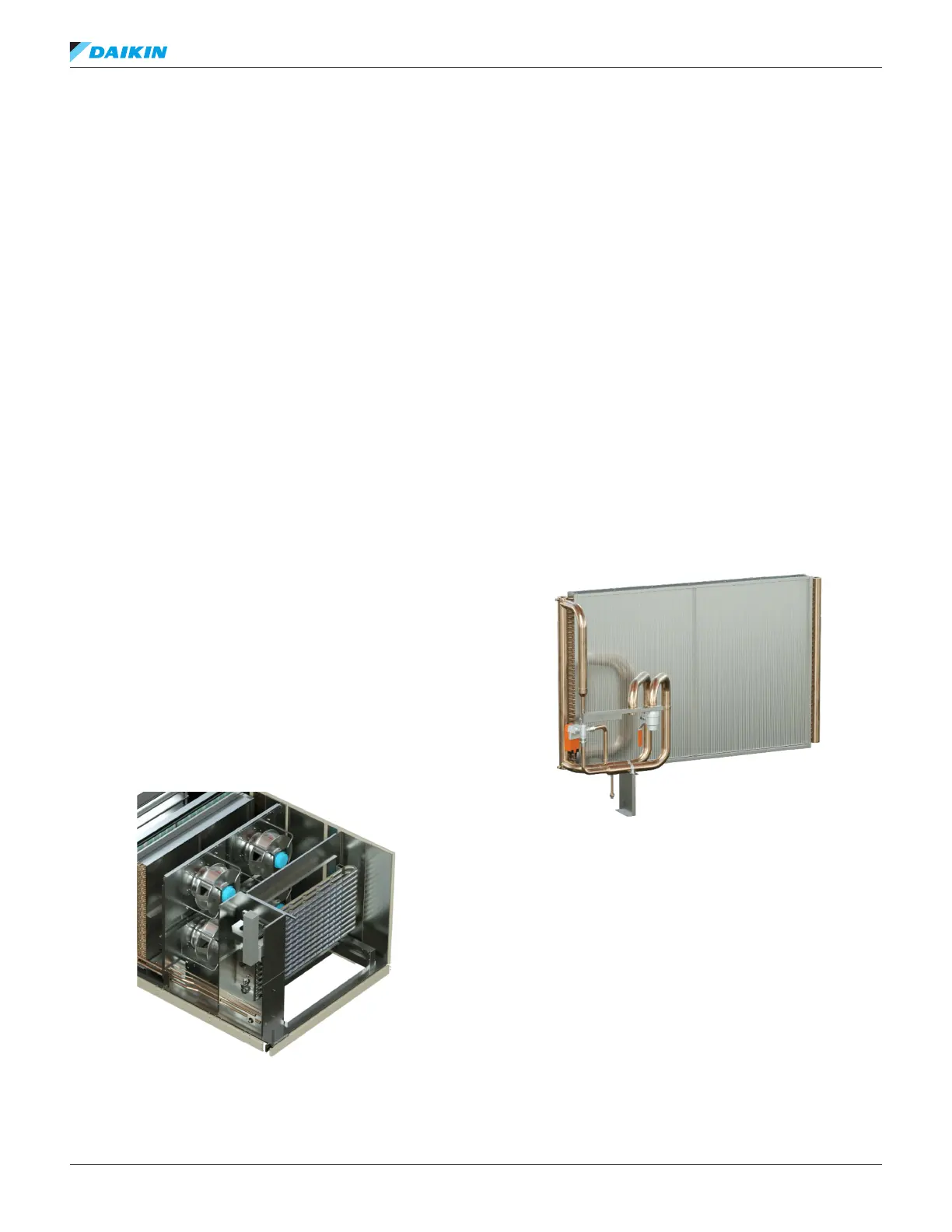

Figure 14: Gas Furnace

• 20 kW to 230 kW selections factory installed and tested

• Multi-stage or SCR control capability for application

exibility

• Durable low watt density, nickel chromium elements for

longer life

• Steam heating coils are 1-row or 2-row, 5/8-in. O.D.

copper tube/aluminum n jet distributing type with

patented HI-F5 n design

• Multiple coil selections oered to size heating output to

application needs

• Heating control fully integrated into the unit’s MicroTech 4

control system

• Factory-installed two or three-way modulating control

valve, piping and modulating spring return actuator

provide system control and full ow through the coil in the

event of a power failure

• Available with factory-mounted freezestat

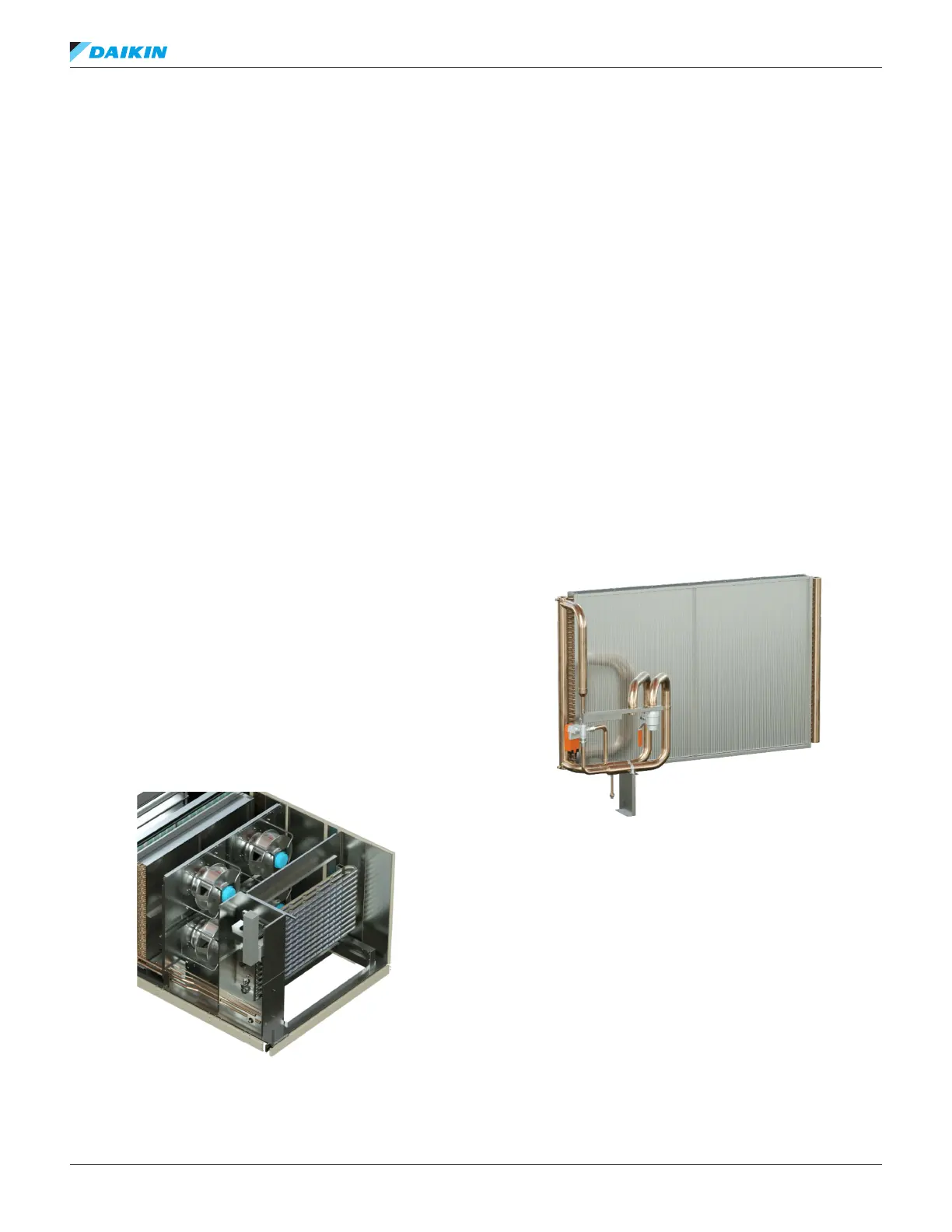

Figure 15: Hot Water or Steam Coil

Loading...

Loading...