1-13

1.4.3 Dehumidification Mode (Option)

The dehumidification operation lowers humidity

using the reheater that heats the air cooled by the

evaporator.

Heat source of the reheater, like the defrosting

operation, uses high temperature refrigerant (hot

gas) discharged from the compressor.

This control is optional, and available for only the

unit equipped with a reheat coil.

The unit equipped with a reheat coil is set to "ON"

at factory referring to *12 Configuration Setting in

paragraph 2.3.

●Setting for dehumidification operation

To execute dehumidification operation, selecting

the dehumidification operation set to "ON", "ON-A",

or "Bulb" is necessary.

ON: When dehumidification operation is executed

ONーA : When dehumidification operation is

executed for the unit without humidity

sensor

Bulb: When dehumidification operation is executed

in the Bulb mode

OFF: When dehumidification operation is not

executed

●Display

After completion of

setting, "DEHUMID" is

indicated on right.

●Dehumidification Operation

Dehumidification operation starts when the

following conditions are met during modulated

cooling in the chilled mode.

RH>Setting humidity RH

& SS<SP±0.7℃ with 5 min. elapse

or SS>SP-0.7℃ with 5 min. elapse

When dehumidification operation starts, it supplies

hot gas to the reheater. EFM runs at high speed.

Modulated Cooling in Chilled

Dehumidification Control

RH>Setting humidity RH

& SS<SP±0.7℃

with 5 min. elapse

or SS>SP-0.7℃

with 5 min. elapse

RH<Setting humidity RH-7%

with 3 min. elapse

or SS>SP+0.5℃

with 20 min. elapse

or SS<SP-0.5℃

with 20 min. elapse

●Cancellation of Dehumidification operation

1) Set dehumidification operation to "OFF"

2) 48 hours elapse after power OFF

3) F-PTI completed

4) Chilled PTI completed

5) Frozen PTI completed

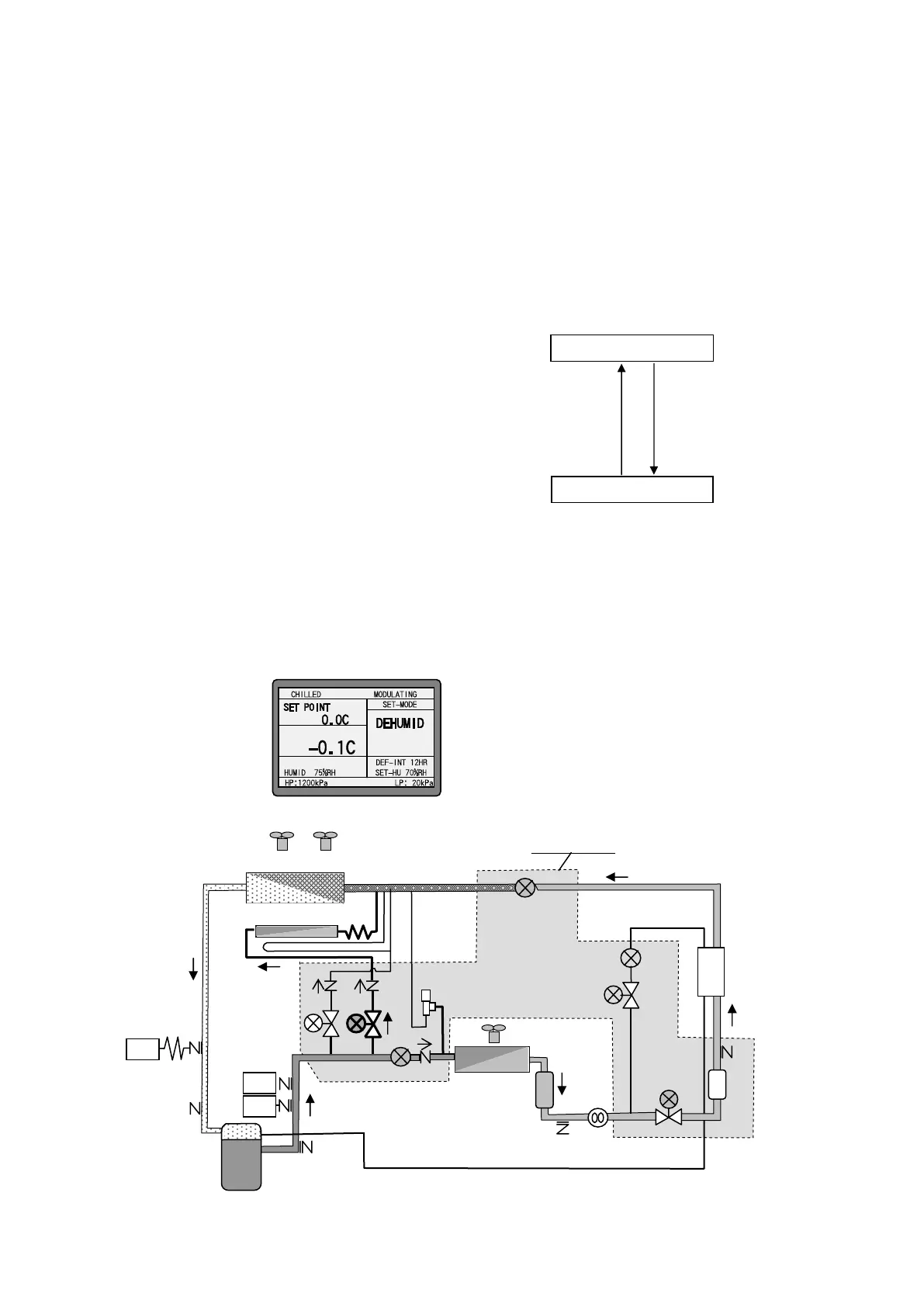

CFM

RSVHSV

DMV

Valve chamber

Economizer

Reheat coil (option)

Condenser

Receiver

HPT

HPS

EMV

ESV

LSV

Drier

EEV

LPT

Sight glass

Evaporator

EFM

PRV

RETURN 2.0C

▲

▼

SUPPLY

Loading...

Loading...