TR08-03

(2008.9.00100)NK

$5,00

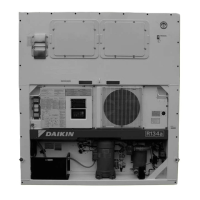

Marine type Container Refrigeration Unit Service Manual LXE10E100 or later

DAIKIN CONTAINER

LXE10E-A

TR 08-03

Marine type

Container Refrigeration Unit

Service Manual

Head Office. Umeda Center Bldg., 4-12, Nakazaki-Nishi 2-chome, Kita-ku, Osaka, 530-8323 Japan.

Tel: 06-6373-4338

Fax: 06-6373-7297

Tokyo Office. JR Shinagawa East Bldg., 11F 18-1, Konan 2-chome, Minato-ku Tokyo, 108-0075 Japan.

Tel: 03-6716-0420

Fax: 03-6716-0230

LXE10E100 or later

(DECOSⅢe)

LXE10E100以降(E)表14巾9.1.qx08.9.410:12AMページ1