3-8

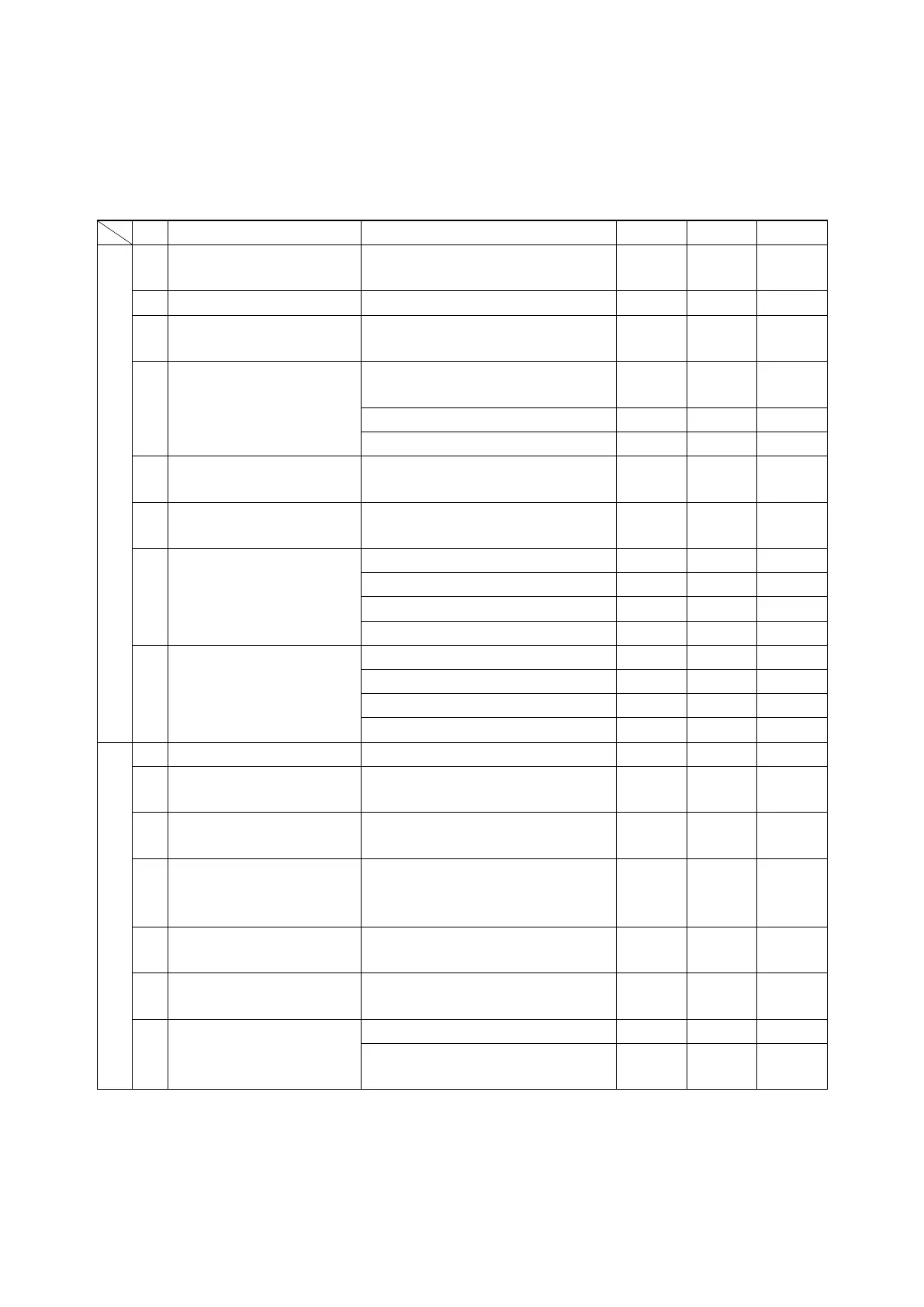

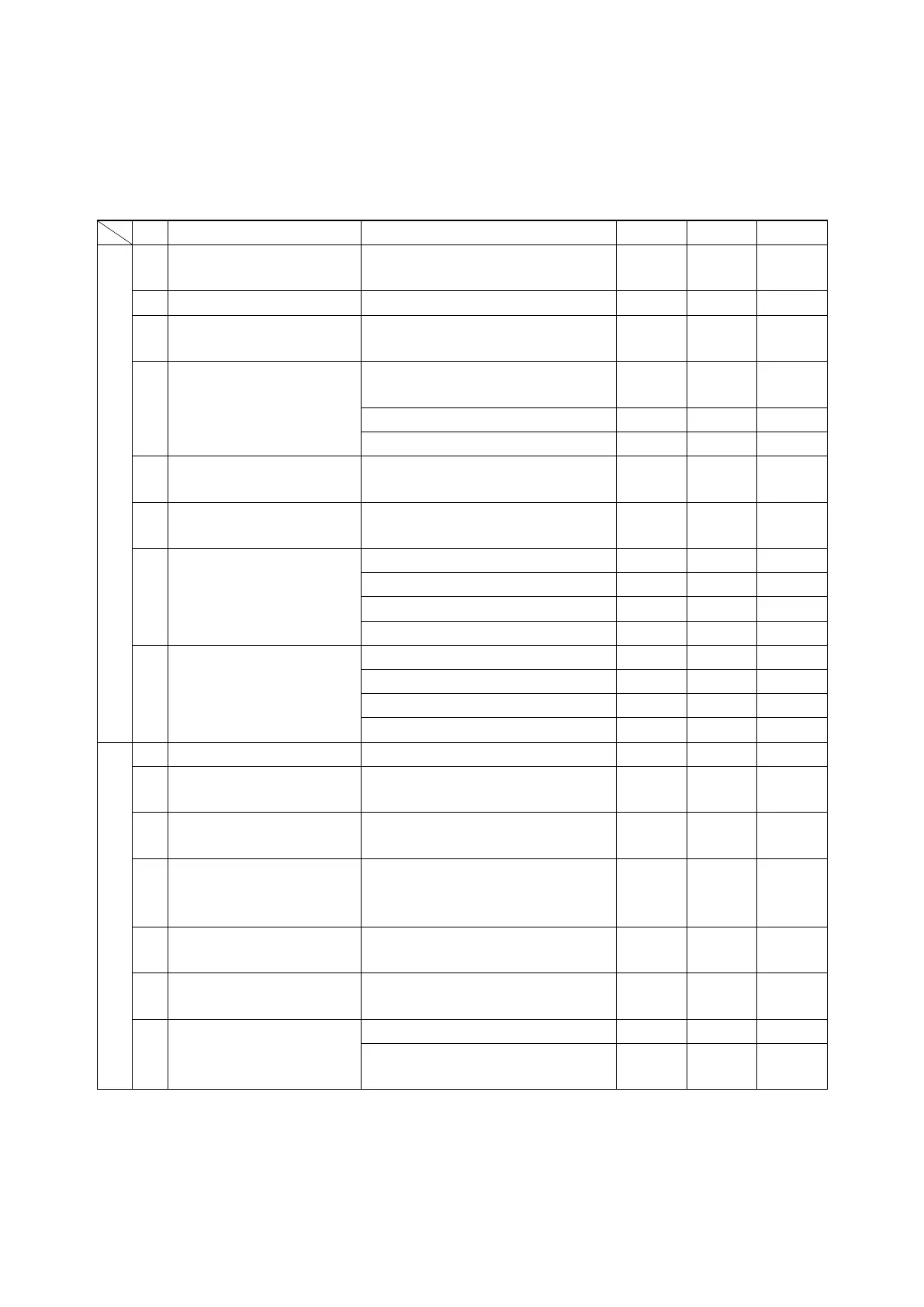

3.4 Periodic Inspection

Always to operate the unit normally, conduct periodic inspections of each part in addition to pre-operation

ones and make adjustments or repairs where necessary. The following table shows an example of the

inspection plan.

No. Inspection item Inspection content 2nd year 4th year 8th year

General structure

1

Inspection for physical

damage

✓✓✓

2 Loose mounting bolts ✓✓✓

3

Condition of panels, hinge

and lock

✓✓✓

4 Control box inspection

1) Cover packing inspection and

replacement

✓✓✓

2) Loose cable gland ✓✓✓

3) Internal cleaning ✓✓✓

5

Sealing condition of holes

through casing frame

Air leakage and clearance ✓✓✓

6

Packing inspection and

replacement

Ventilator cover packing ✓✓✓

7 Painted area recondition

1) Compressor ✓✓✓

2) Receiver ✓✓✓

3) Solenoid valve (coil cap) ✓✓✓

4) Unit ✓✓

8 Repainting

1) Compressor ✓

2) Receiver ✓

3) Condenser fan motor ✓

4) Condenser fan ✓

Refrigerant system

1 Refrigerant leakage ✓✓✓

2 Compressor

Water entering to compressor

terminal

✓✓✓

3

Inspection and replacement

of sight glass

✓

4

Condition of fasteners on

the refrigerant pipes and

gauge pipes

✓✓✓

5

Condition of thermal

insulation of refrigerant pipe

✓✓✓

6

Evaporator coil cleaning

(by water)

✓✓✓

7 Condenser coil cleaning

1) Water-cleaning ✓✓✓

2) Steam-cleaning (after pumping

down the refrigerant)

✓✓✓

Loading...

Loading...